Yamaha XV1700P, XV1700PC. Service Manual - part 23

5 - 86

ENG

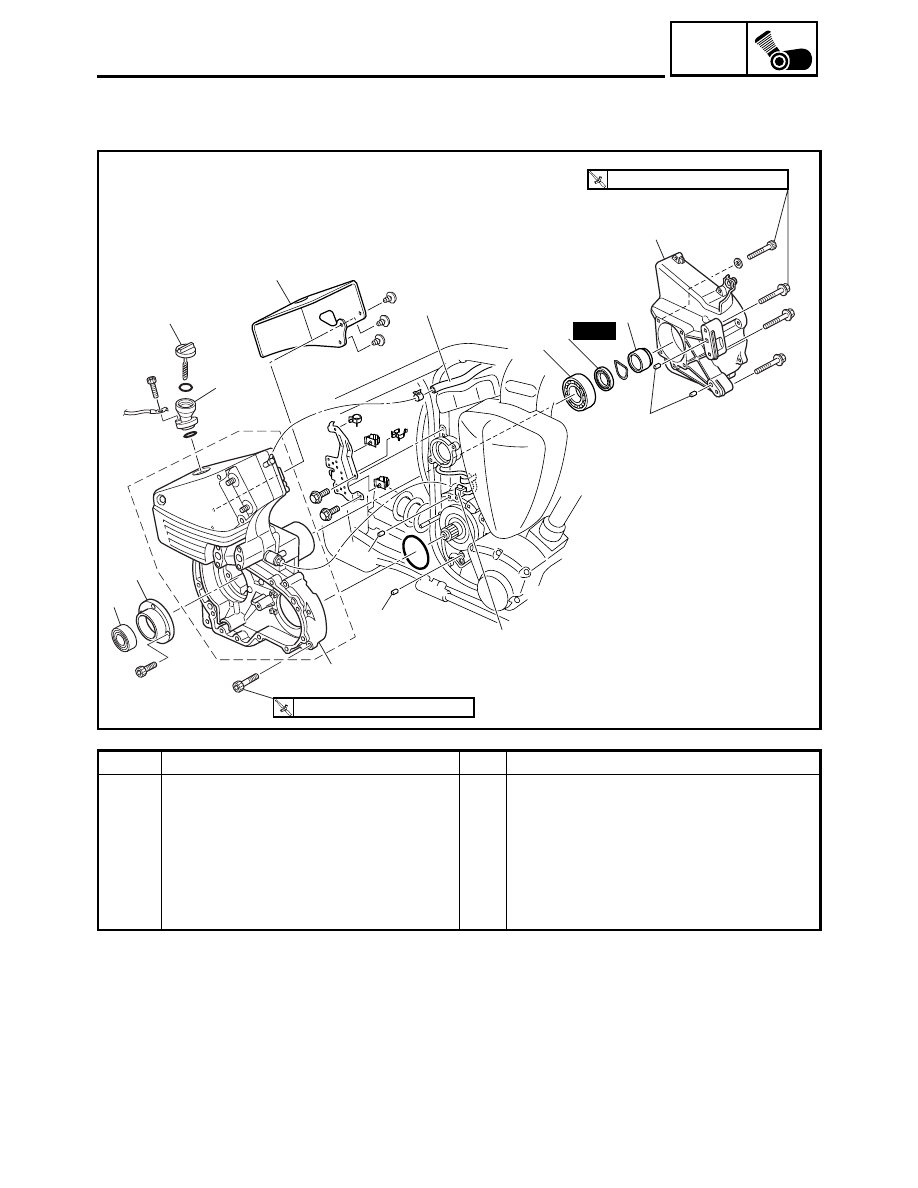

TRANSFER GEAR CASE

3

4

5

13

12

10

(4)

(4)

11

11

2

1

12

9

8

7

6

(5)

T

R

.

.

30 Nm (3.0 m

•

kg, 22 ft

•

Ib)

T

R

.

.

50 Nm (5.0 m

•

kg, 36 ft

•

Ib)

New

Order

Job/Part

Q’ty

Remarks

9

Oil seal

1

10

Transfer gear case

1

11

Dowel pin

2

12

Bearing

2

13

Bearing housing

1

For installation, reverse the removal

procedure.