Yamaha XV1700P, XV1700PC. Service Manual - part 21

5 - 54

ENG

CYLINDERS AND PISTONS

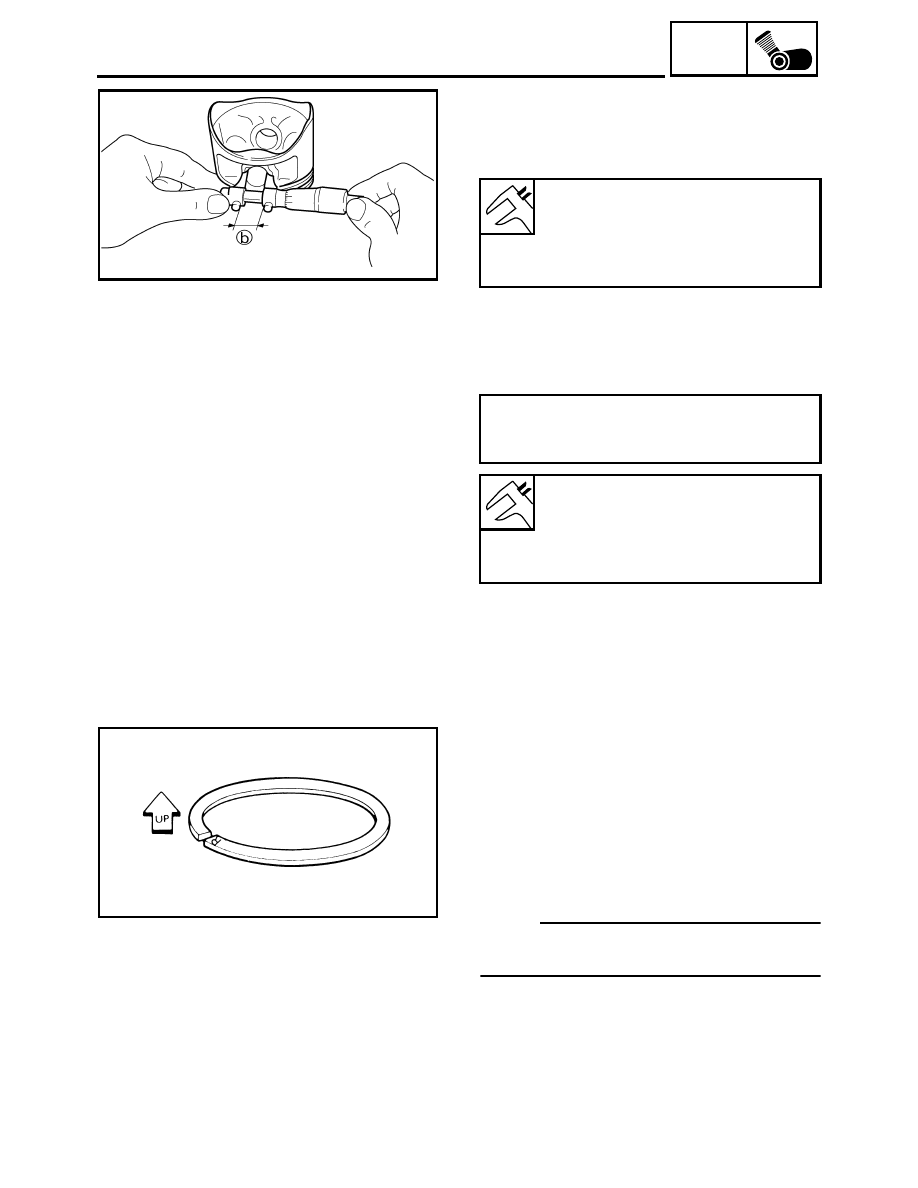

3. Measure:

• piston pin bore diameter (in the piston)

b

Out of specification

→

Replace the piston

pin.

4. Calculate:

• piston-pin-to-piston-pin-bore clearance

Out of specification

→

Replace the piston

pin and piston as a set.

Piston pin bore diameter (in the

piston)

22.004 ~ 22.015 mm

(0.8663 ~ 0.8667 in)

<Limit>: 22.045 mm (0.8679 in)

Piston-pin-to-piston clearance =

Piston pin bore diameter (in the piston)

b

- Piston pin outside diameter

a

Piston-pin-to-piston pin bore

clearance

0.004 ~ 0.024 mm

(0.00016 ~ 0.00094 in)

<Limit>: 0.074 mm (0.0029 in)

EAS00268

INSTALLING THE PISTONS AND

CYLINDERS

The following procedure applies to all of the

pistons and cylinders.

1. Install:

• top ring

• 2nd ring

• oil ring

NOTE:

_

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.