Yamaha XV19SW(C), XV19W(C), XV19MW(C), XV19CTSW(C), XV19CTW(C), XV19CTMW(C). Service Manual - part 21

TRANSMISSION

5-112

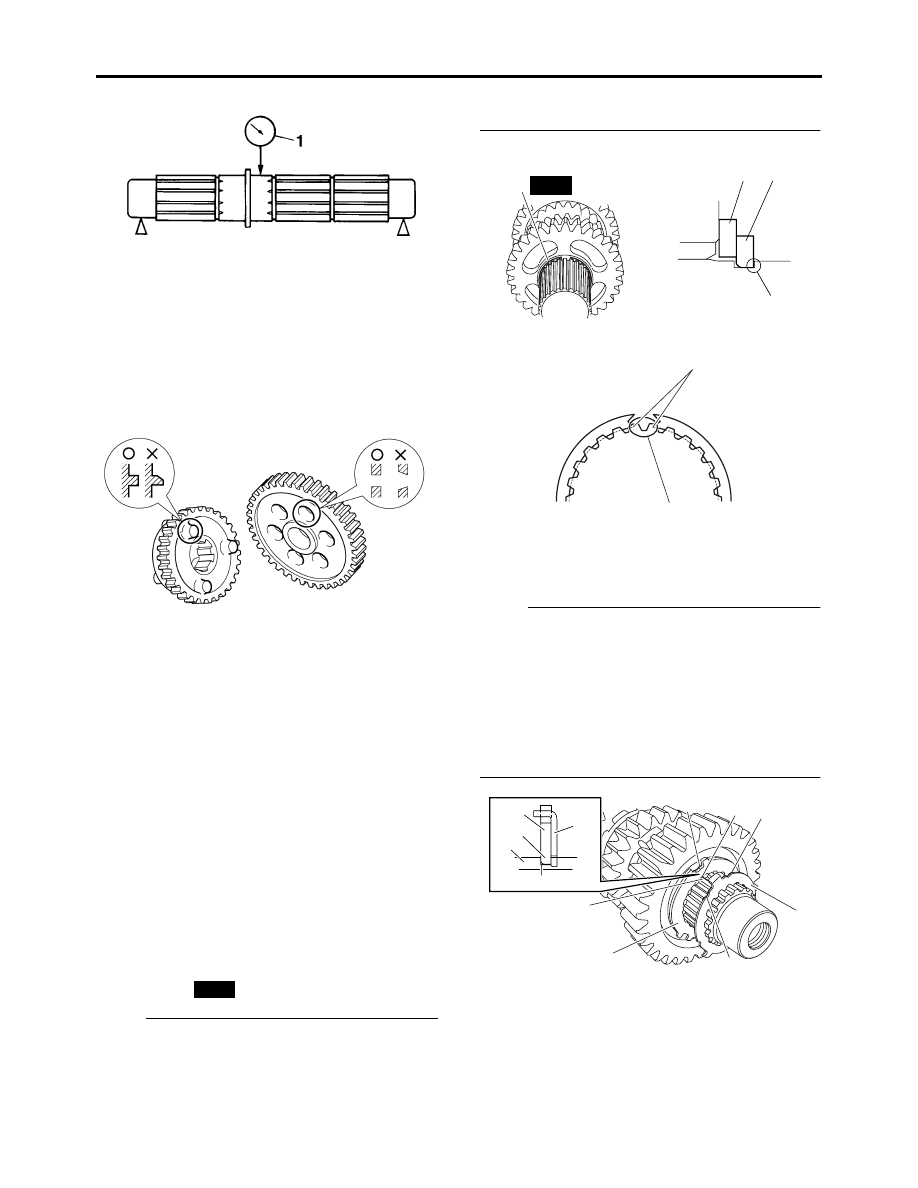

3. Check:

• Transmission gears

Blue discoloration/pitting/wear

→

Replace

the defective gear(s).

• Transmission gear dogs

Cracks/damage/rounded edges

→

Replace

the defective gear(s).

4. Check:

• Transmission gear engagement

(each pinion gear to its respective wheel

gear)

Incorrect

→

Reassemble the transmission

axle assemblies.

5. Check:

• Transmission gear movement

Rough movement

→

Replace the defective

part(s).

6. Check:

• Circlips

Bends/damage/looseness

→

Replace.

ET1D71006

ASSEMBLING THE MAIN AXLE AND DRIVE

AXLE

1. Install:

• Toothed washer “1”

• Circlip “2”

NOTE:

• Be sure the circlip sharp-edged corner “a” is

positioned opposite side to the toothed washer

and gear. (For main axle)

• Install the circlip so that both ends “b” rest on

the sides of a spline “c” with both axles aligned.

2. Install:

• Toothed lock washer retainer “1”

• Toothed lock washer “2”

NOTE:

• With the toothed lock washer retainer “1” in the

groove “a” in the axle, align the projection “c”

on the retainer with an axle spline “b”, and then

install the toothed lock washer “2”.

• Be sure to align the projection on the toothed

lock washer that is between the alignment

marks “e” with the alignment mark “d” on the

retainer.

EAS26320

INSTALLING THE SHIFT FORKS AND SHIFT

DRUM ASSEMBLY

1. Install:

• Shift forks 1 “1”

• Shift fork 2 “2”

• Shift drum assembly “3”

New

1

2

2

New

a

b

c

2

e

e

d

b

c

1

c

b

a

2

1