Yamaha XV19SW(C), XV19W(C), XV19MW(C), XV19CTSW(C), XV19CTW(C), XV19CTMW(C). Service Manual - part 19

ELECTRIC STARTER

5-80

7. Check:

• Gear teeth

Damage/wear

→

Replace the gear.

8. Check:

• Bearings

• Oil seal

Damage/wear

→

Replace the defective

part(s).

EAS24800

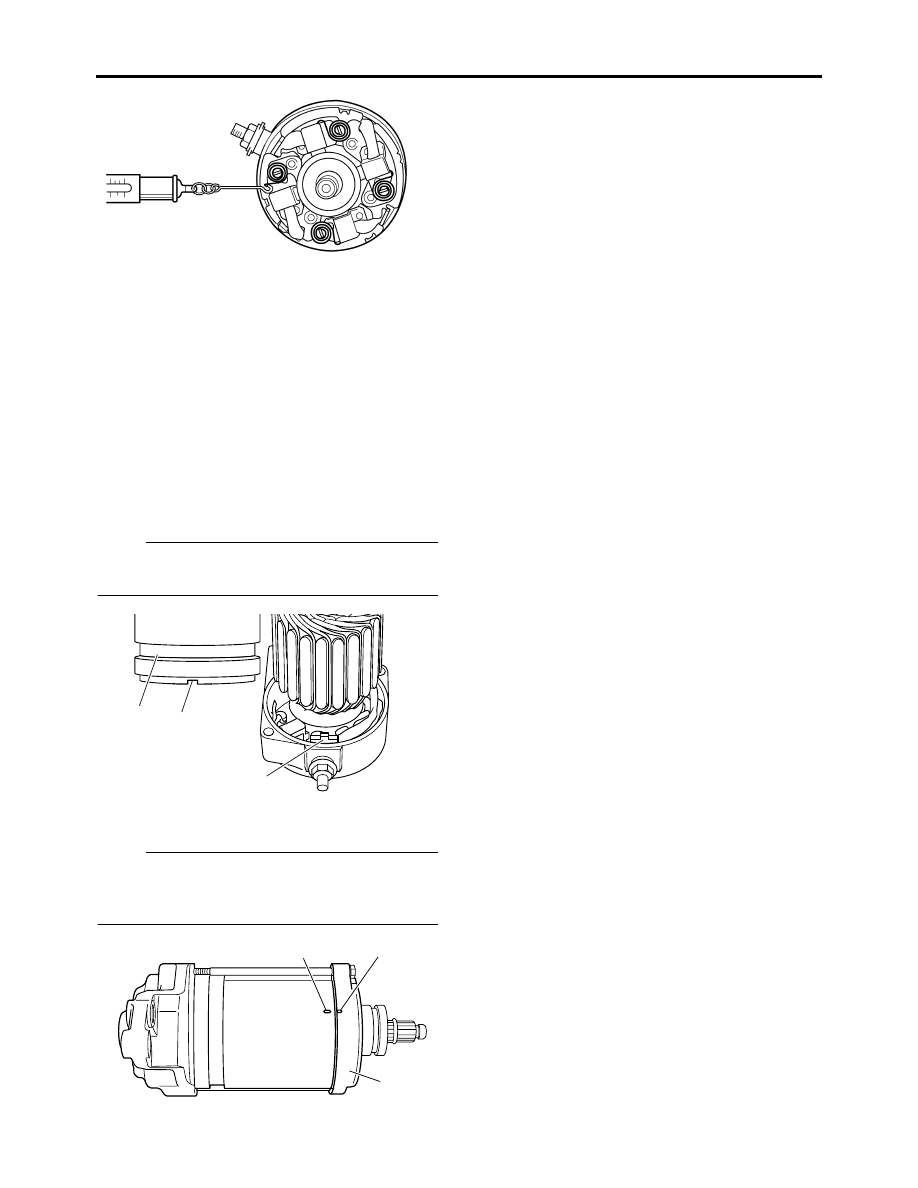

ASSEMBLING THE STARTER MOTOR

1. Install:

• Starter motor yoke “1”

NOTE:

Align the projection “a” on the brush holder with

the slot “b” in the starter motor yoke.

2. Install:

• Starter motor front cover “1”

NOTE:

Align the match mark “a” on the starter motor

yoke with the match mark “b” on the starter mo-

tor front cover.

1

b

a

a

b

1