Yamaha XV19SW(C), XV19W(C), XV19MW(C), XV19CTSW(C), XV19CTW(C), XV19CTMW(C). Service Manual - part 7

ENGINE

3-10

10.Install:

• Air filter case

Refer to “GENERAL CHASSIS” on page 4-1.

• Fuel tank

Refer to “FUEL TANK” on page 6-1.

• Rider seat bracket assembly

• Rider seat

Refer to “GENERAL CHASSIS” on page 4-1.

EAS20700

CHECKING THE IGNITION TIMING

NOTE:

Prior to checking the ignition timing, check the

wiring connections of the entire ignition system.

Make sure all connections are tight and free of

corrosion.

1. Stand the vehicle on a level surface.

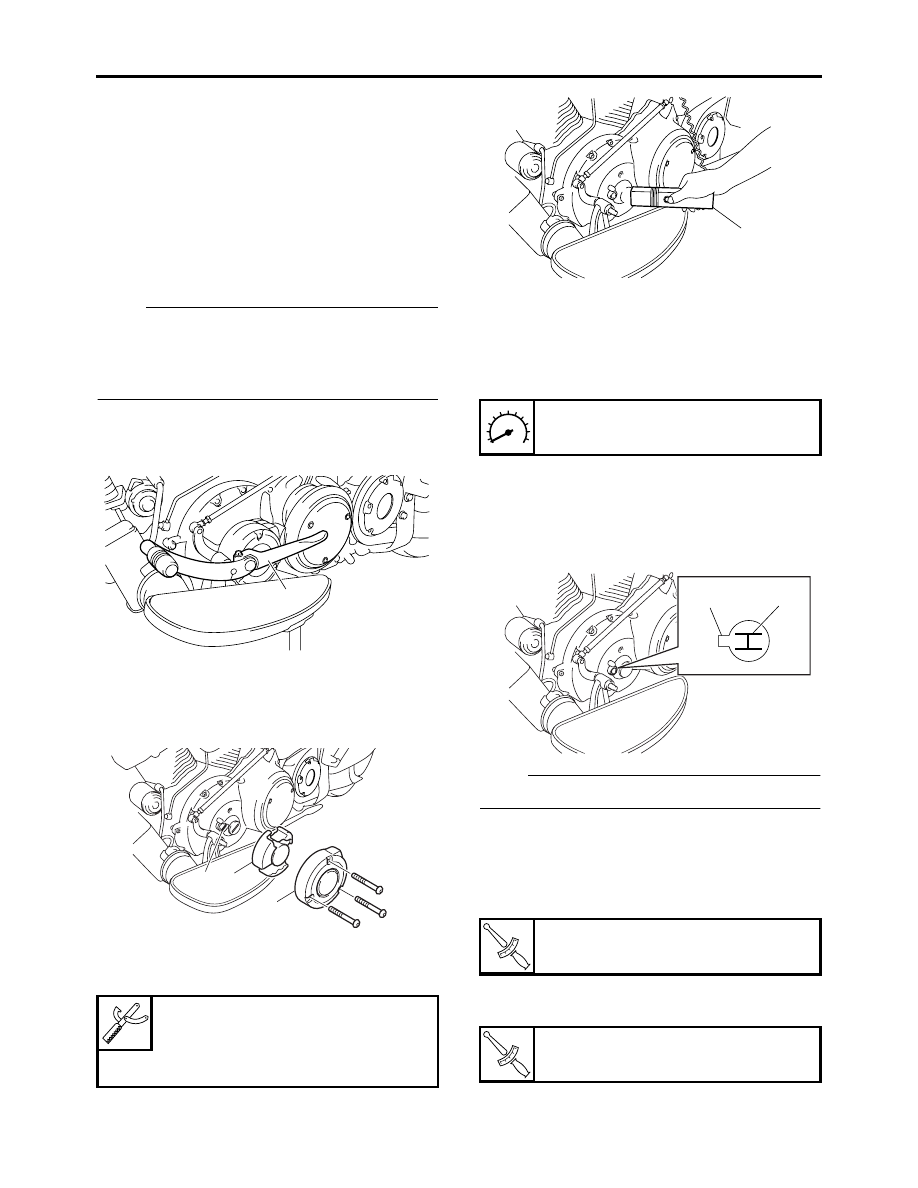

2. Remove:

• Shift pedal assembly “1”

3. Remove:

• Damper cover “1”

• Damper “2”

• Timing mark accessing screw “3”

4. Connect:

• Timing light “1”

• Tachometer

5. Check:

• Ignition timing

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

a. Start the engine, warm it up for several min-

utes, and then let it run at the specified en-

gine idling speed.

b. Check that pointer “a” on the clutch cover is

within the firing range “b” on the crankshaft

position sensor rotor.

Incorrect firing range

→

Check the ignition

system.

NOTE:

The ignition timing is not adjustable.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

6. Install:

• Timing mark accessing screw

• Damper

• Damper cover

7. Install:

• Shift pedal assembly “1”

Timing light

90890-03141

Inductive clamp timing light

YU-03141

1

3 2

1

Engine idling speed

850–950 r/min

T

R

.

Damper cover bolt

10 Nm (1.0 m·kg, 7.2 ft·lb)

T

R

.

Shift pedal bolt

18 Nm (1.8 m·kg, 13 ft·lb)

1

a

b