Yamaha YFM45FAR, YFM450FAR. Service Manual - part 13

4 - 66

ENG

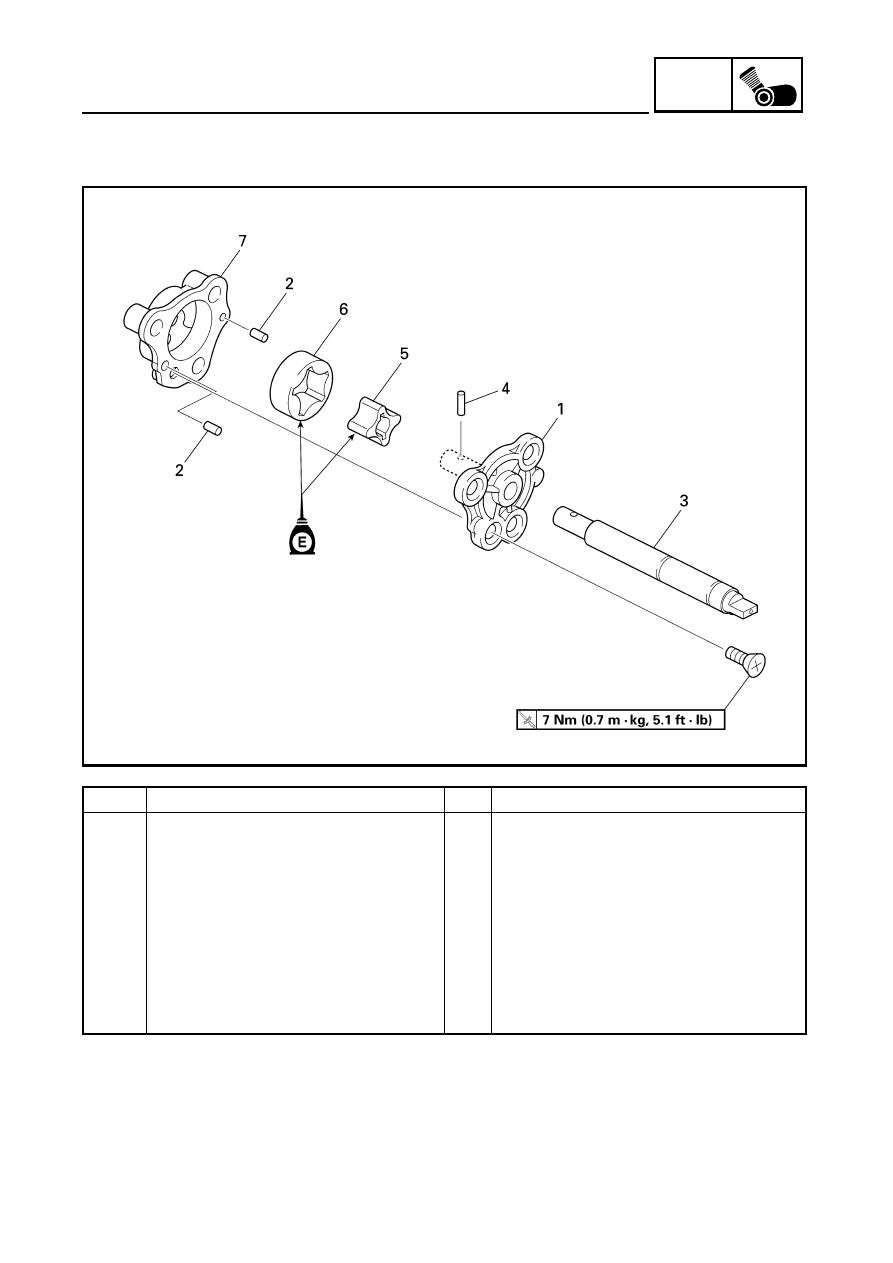

CRANKSHAFT AND OIL PUMP

OIL PUMP

Order

Job name/Part name

Q’ty

Remarks

Disassembling the oil pump

Remove the parts in the order below.

1

Rotor cover

1

2

Pin

2

3

Shaft

1

4

Pin

1

5

Inner rotor

1

6

Outer rotor

1

7

Oil pump housing

1

For assembly, reverse the disassembly

procedure.