Yamaha YFM45FAR, YFM450FAR. Service Manual - part 11

4 - 34

ENG

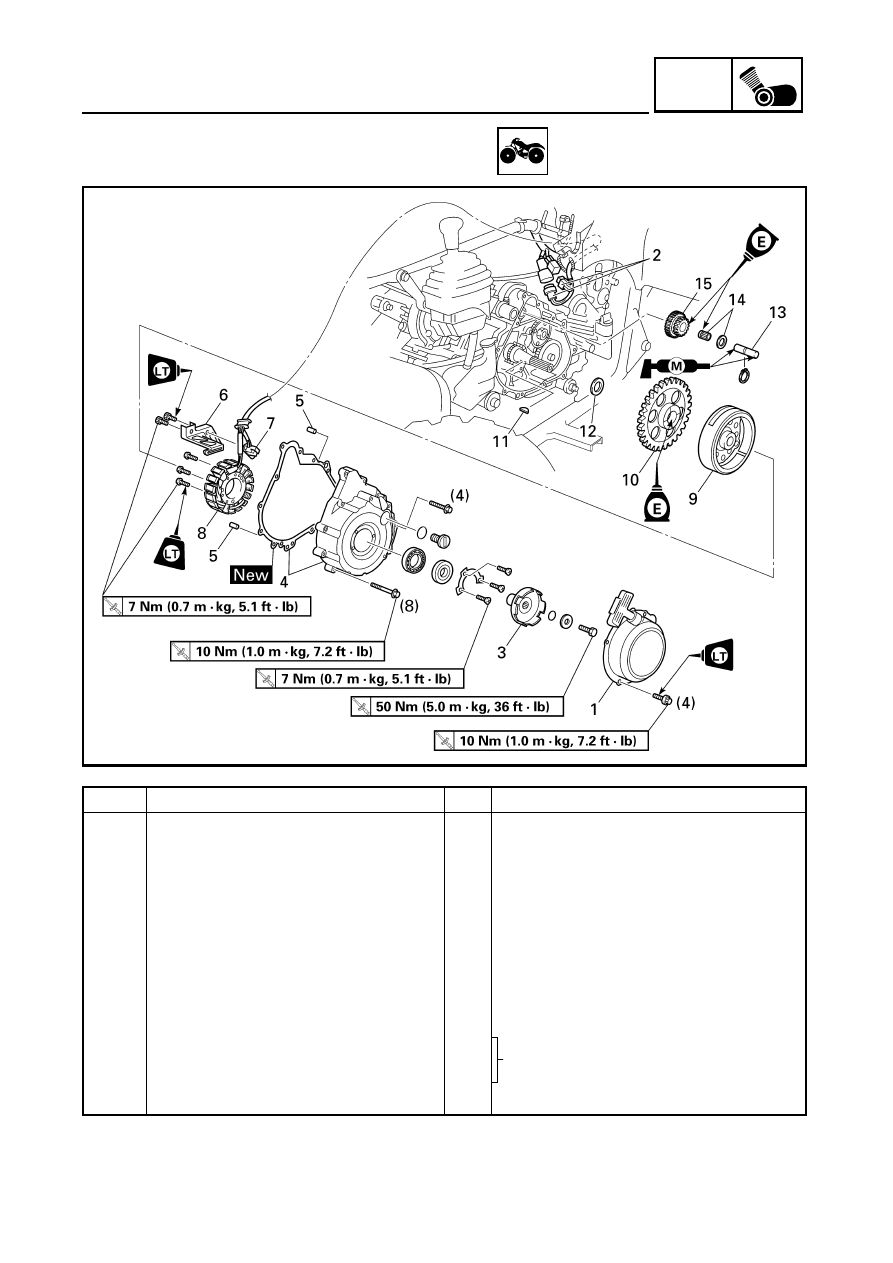

RECOIL STARTER AND A.C. MAGNETO

RECOIL STARTER AND A.C. MAGNETO

Order

Job name/Part name

Q’ty

Remarks

Removing the CDI magneto

Remove the parts in the order below.

Engine oil

Drain.

Refer to “CHANGING THE ENGINE OIL”

in CHAPTER 3.

Seat and side panels

Refer to “SEAT AND SIDE PANELS” in

CHAPTER 3.

Left footrest board

Refer to “FOOTREST BOARDS” in

CHAPTER 3.

1

Recoil starter assembly

1

2

A.C. magneto coupler

2

Disconnect.

3

Starter pulley

1

Refer to “REMOVING/INSTALLING THE

A.C. MAGNETO”.

4

Crankcase cover (left)/gasket

1/1

5

Dowel pin

2

6

Lead holder

1