Yamaha YFM45FAR, YFM450FAR. Service Manual - part 7

3 - 39

CHK

ADJ

CHECKING THE FRONT BRAKE PAD/

CHECKING THE REAR BRAKE PAD

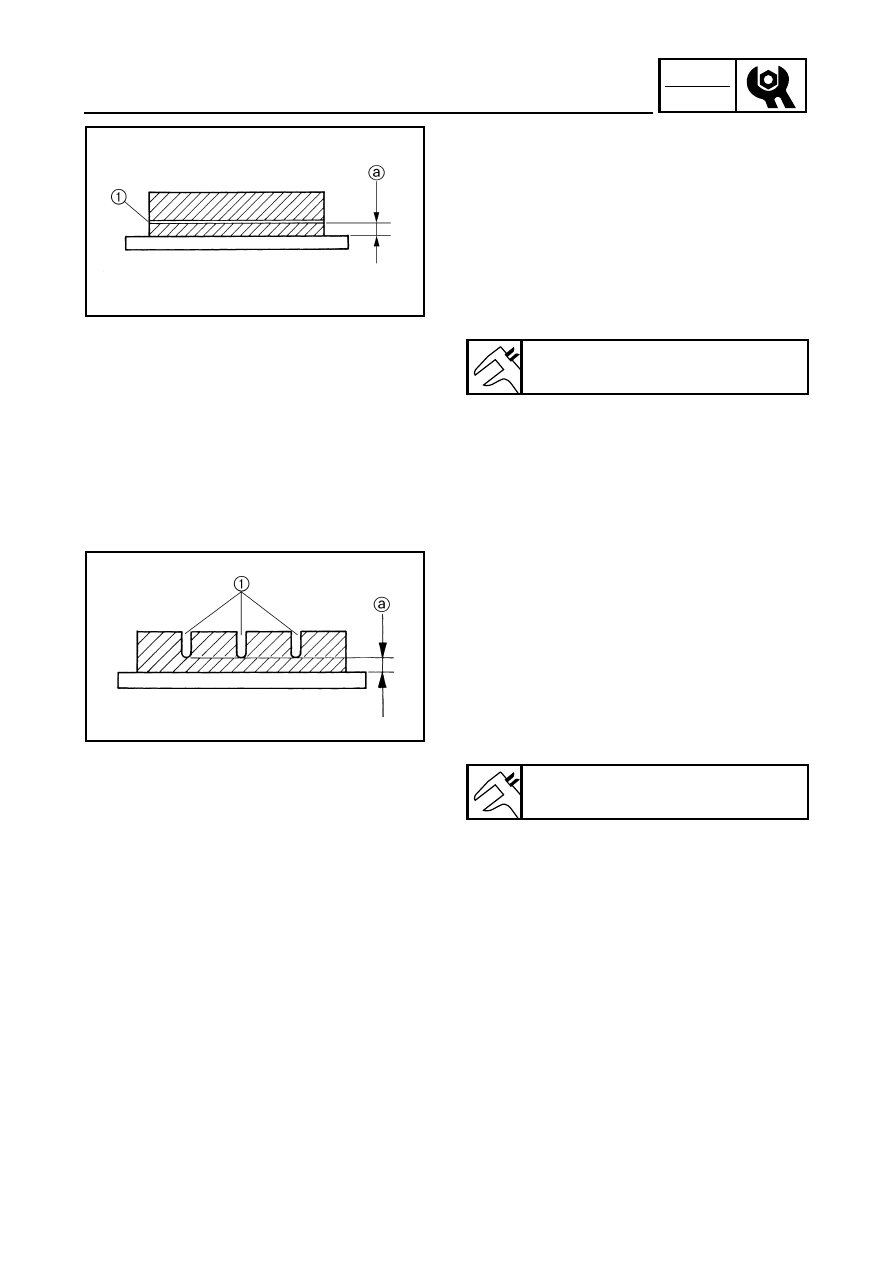

CHECKING THE FRONT BRAKE PAD

1.Remove:

●

Front wheels

2.Check:

●

Brake pad

Wear indicators groove

1

almost touch the

brake disc

→

Replace the brake pads as a

set.

Refer to “FRONT AND REAR BRAKES” in

CHAPTER 8.

3.Operate the brake lever.

4.Install:

●

Front wheels

Brake pad wear limit

a

:

1 mm (0.04 in)

CHECKING THE REAR BRAKE PAD

1.Remove:

●

Rear wheel (left)

2.Check:

●

Brake pad

Wear indicator groove

1

almost

disappeared

→

Replace the brake pads as a

set.

Refer to “FRONT AND REAR BRAKES” in

CHAPTER 8.

3.Operate the brake lever or brake pedal.

4.Install:

●

Rear wheel (left)

Brake pad wear limit

a

:

1 mm (0.04 in)