Yamaha YFM45FAR, YFM450FAR. Service Manual - part 6

3 - 23

CHK

ADJ

CHECKING THE ENGINE OIL LEVEL

CHECKING THE ENGINE OIL LEVEL

1.Place the machine on a level surface.

2.Remove:

●

Engine side panel

Refer to “SEAT, CARRIERS, FENDERS

AND FUEL TANK”.

3.Check:

●

Engine oil level

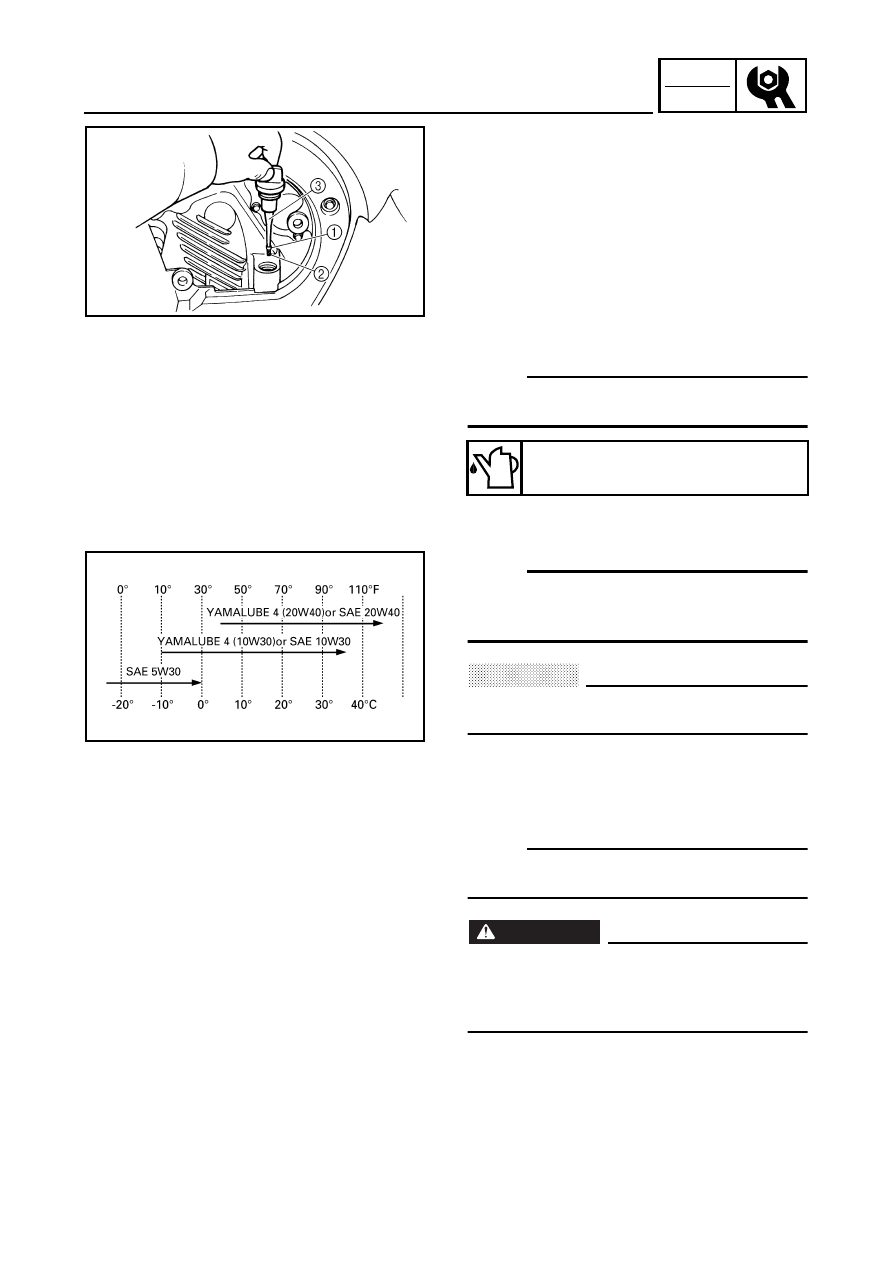

Oil level should be between the maximum

level mark

1

and minimum level mark

2

.

Oil level low

→

Add oil to the proper level.

NOTE:

Do not screw the dipstick

3

in when checking

the oil level.

Recommended oil:

Follow the left chart.

NOTE:

Recommended oil classification:

API Service “SE”, “SF” type or equivalent (e.g.

“SF–SE–CC”, “SF–SE–SD” etc.)

CAUTION:

Do not allow foreign material to enter the

crankcase.

4.Start the engine and let it warm up for

several minutes.

5.Stop the engine and check the oil level

again.

NOTE:

Wait a few minutes until the oil settles before

checking the oil level.

WARNING

Never remove the dipstick just after high

speed operation because the heated oil

could spurt out. Wait until the oil cools

down before removing the dipstick.

6.Install:

●

Engine side panel