ATV Arctic Cat 2001 Line. Service Manual - part 26

Fig. 9-16

AF680D

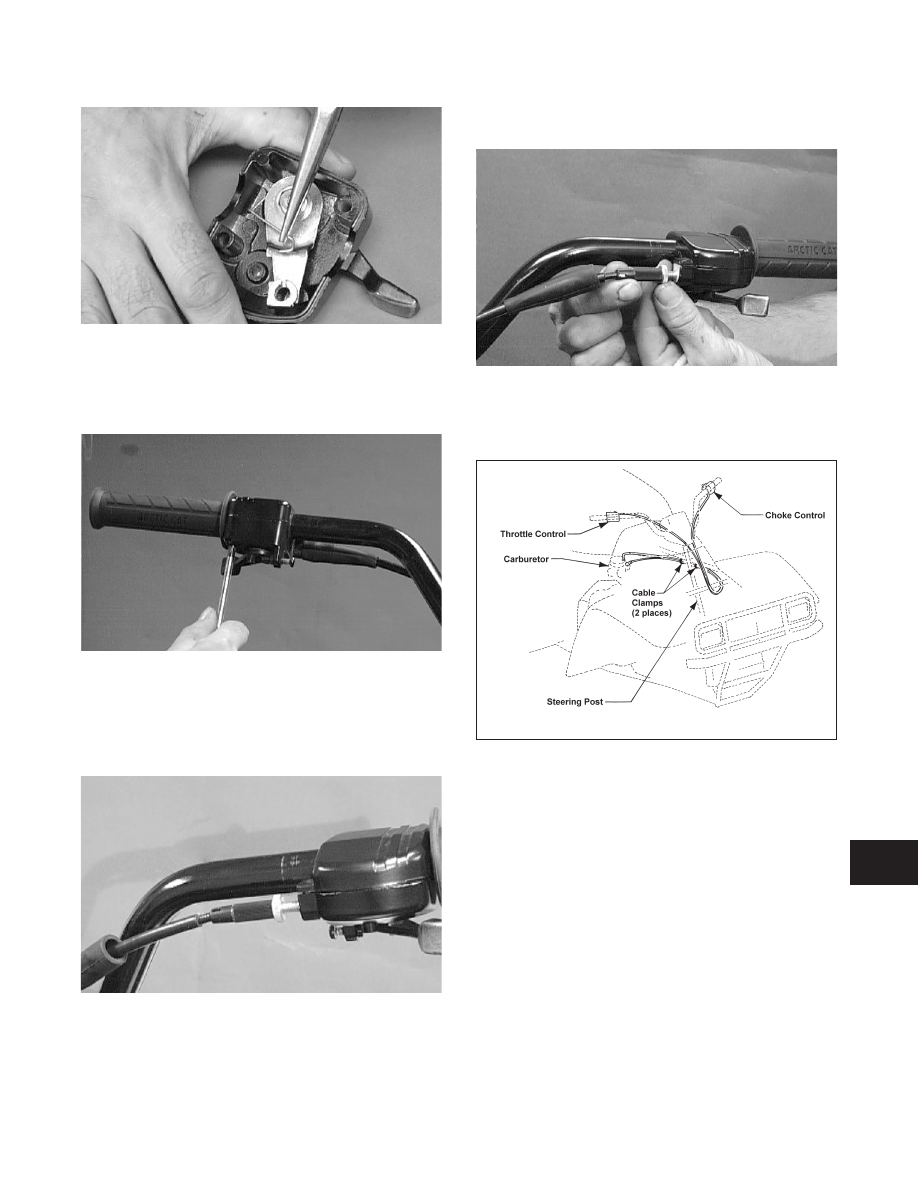

3. Place the two halves of the throttle control onto the

handlebars and secure with the two machine

screws.

Fig. 9-17

AL610D

ADJUSTING

1. Slide the boot back to reveal the jam nut; then

loosen the jam nut.

Fig. 9-18

AF682D

2. Rotate the adjuster sleeve until 0.5-1.0 mm

(0.02-0.04 in.) is attained.

Fig. 9-19

AL611D

3. Secure the adjustment by tightening the jam nut;

then slide the boot over the jam nut.

Fig. 9-20

0732-412

9

9-7