ATV Arctic Cat 2002. Service Manual - part 23

8-14

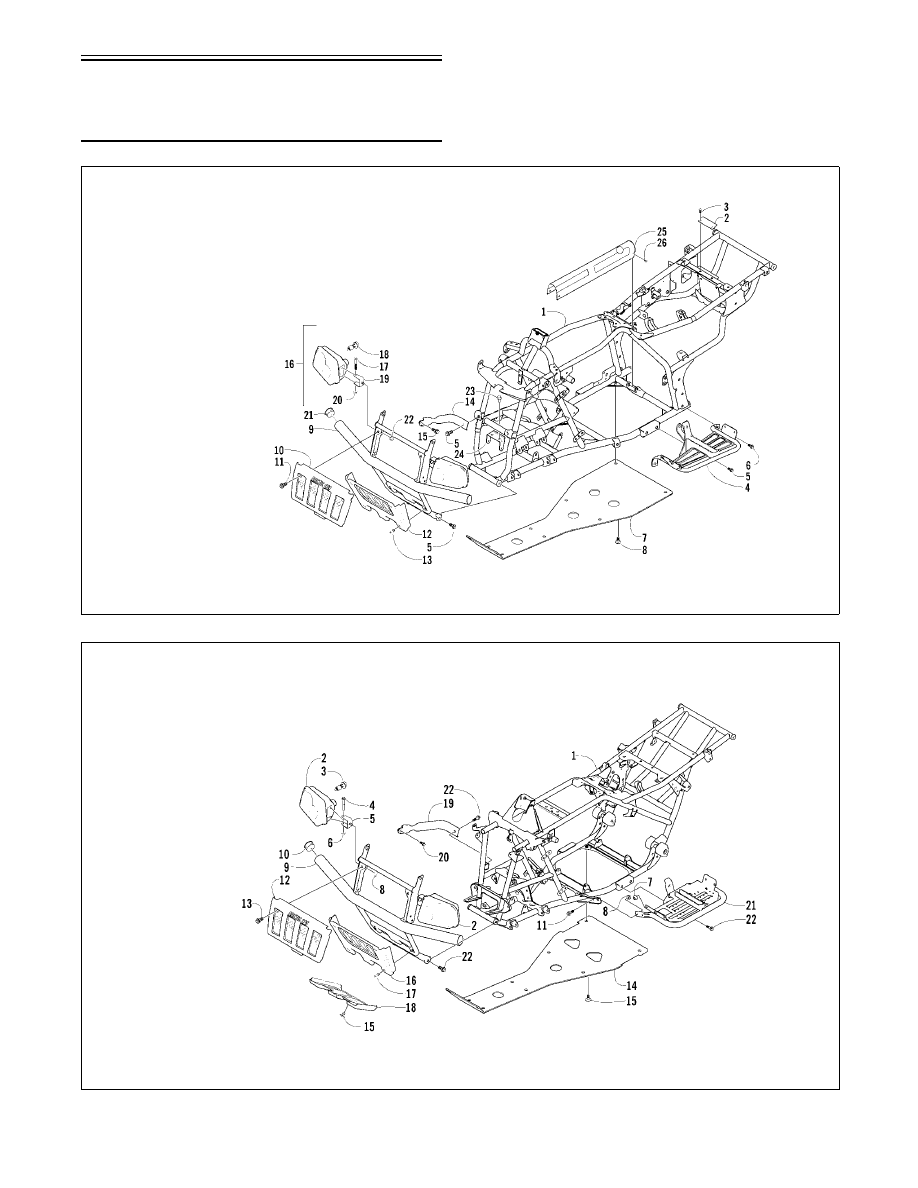

Frame/Exhaust

Assembly Schematics

0737-752

0737-594

KEY

1. Main Frame

2. Bracket

3. Machine Screw

4. Footrest

5. Cap Screw

6. Cap Screw

7. Belly Panel

8. Body Screw

9. Bumper

10. Grille

11. Machine Screw

12. Grille

13. Machine Screw

14. Bumper

15. Cap Screw

16. Headlight Assy

17. Cap Screw

18. Bulb

19. Bracket

20. Nut

21. Bumper Cap

(300 4x4)

22. Nut

23. Cap Screw*

24. Bracket*

25. Driveshaft

Cover*

26. Cap Screw*

250/300

KEY

1. Main Frame

2. Headlight Assy

3. Bulb

4. Cap Screw

5. Bracket

6. Nut

7. Nut

8. Nut

9. Bumper

10. Cap

11. Cap Screw

12. Grille

13. Machine Screw

14. Belly Panel

15. Body Screw

16. Grille

17. Machine Screw

18. Skid Plate

19. Mounting Channel

20. Cap Screw

21. Footrest

22. Cap Screw

400/500 ACT

!

NOTE: Some components may vary from model

to model. The technician should use discretion

and sound judgment.

* 4x4 Models