ATV Arctic Cat 2002. Service Manual - part 22

7-14

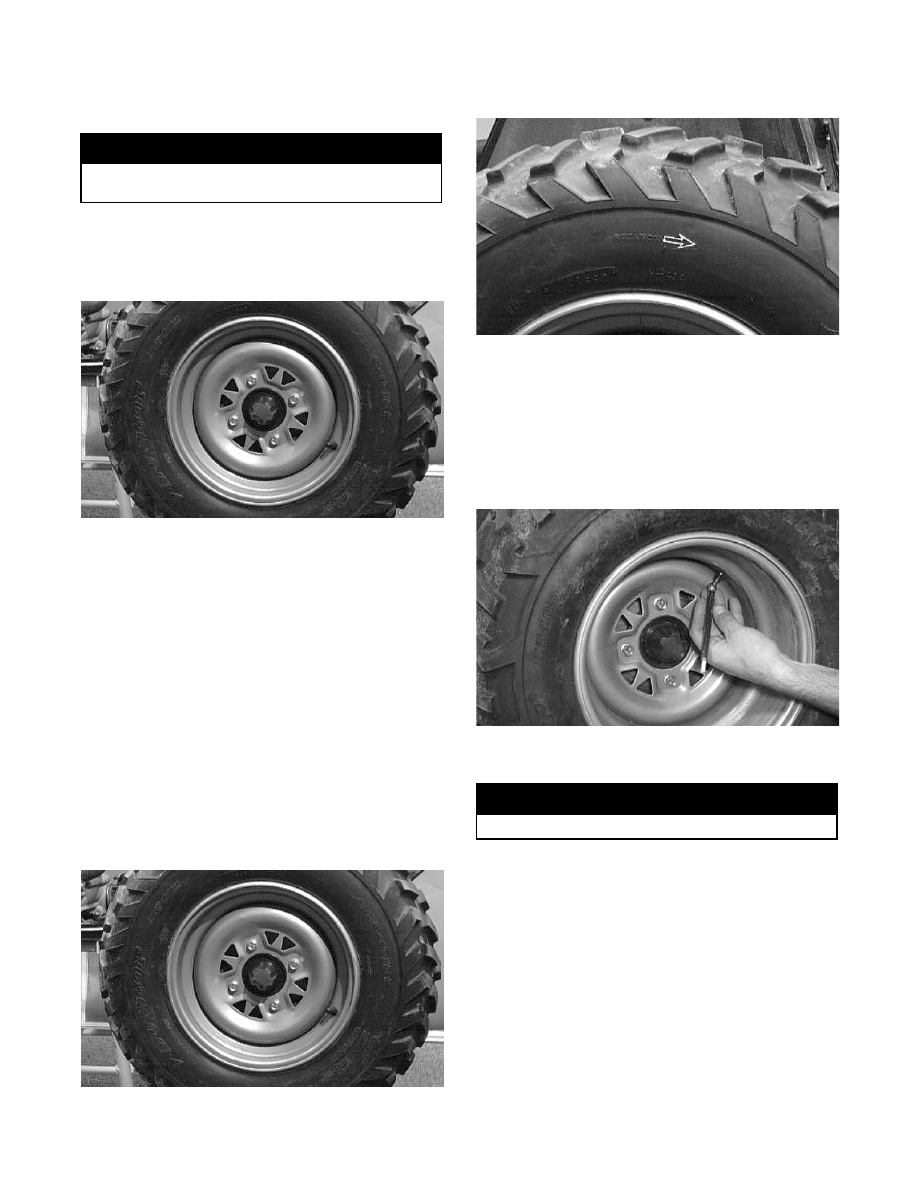

REMOVING

1. Secure the ATV on a support stand to elevate the

wheels.

2. Remove the wheels.

!

NOTE: Keep left-side and right-side wheels sepa-

rated for installing them on their proper sides.

AF611D

CLEANING AND INSPECTING

!

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Clean the wheels and hubs with parts-cleaning

solvent.

2. Clean the tires with soap and water.

3. Inspect each wheel for cracks, dents, or bends.

4. Inspect each tire for cuts, wear, missing lugs, and

leaks.

INSTALLING

1. Install each wheel on its hub.

AF611D

!

NOTE: Make sure each wheel is installed on its

proper hub as noted in removing (the “rotation

arrow” must indicate forward direction of rotation).

AF612D

2. Tighten to 5.5 kg-m (40 ft-lb).

CHECKING/INFLATING

1. Using an air pressure gauge, measure the air

pressure in each tire. Adjust the air pressure as

necessary to meet the recommended inflation

pressure.

AL628D

2. Inspect the tires for damage, wear, or punctures.

!

NOTE: If repair is needed, follow the instructions

found on the tire repair kit or remove the wheel

and have it repaired professionally.

!

NOTE: Be sure all tires are the specified size and

have identical tread pattern.

3. Check the front wheel toe-in and toe-out and

adjust as necessary (see Section 8).

4. Test drive the ATV on a dry, level surface and note

any pulling to the left or right during acceleration,

deceleration, and braking.

! WARNING

Make sure the ATV is solidly supported on the sup-

port stand to avoid injury.

! WARNING

Do not operate the ATV if tire damage exists.