Suzuki GSX-R1000. Service Manual - part 33

4B-4 Front Brakes:

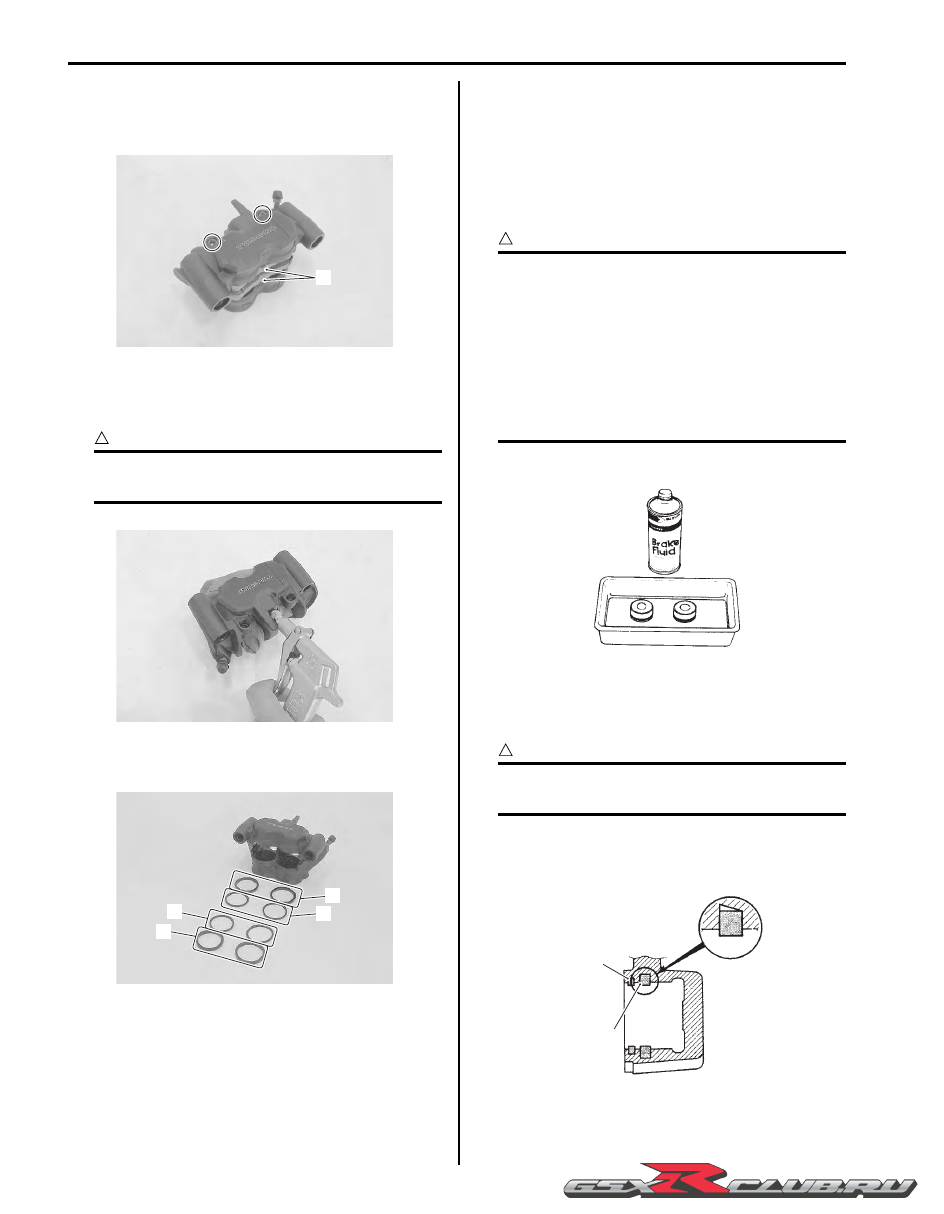

Disassembly

1) Remove the brake pads (1) and spring from the

caliper by removing the pad mounting pins.

2) Place a rag over the pistons to prevent them from

popping out and then force out the pistons using

compressed air.

CAUTION

!

Do not use high pressure air to prevent

piston damage.

3) Remove the dust seals (2) and piston seals (3) from

both sides of the caliper.

Assembly

Assemble the caliper in the reverse order of

disassembly. Pay attention to the following points:

• Wash the caliper bores and pistons with specified

brake fluid. Particularly wash the dust seal grooves

and piston seal grooves.

BF: Brake fluid (DOT 4)

CAUTION

!

• Wash the caliper components with fresh

brake fluid before reassembly. Never use

cleaning solvent or gasoline to wash them.

• Do not wipe the brake fluid off after

washing the components.

• When washing the components, use the

specified brake fluid. Never use different

types of fluid or cleaning solvent such as

gasoline, kerosine or the others.

• Apply the brake fluid to piston seals (1) and dust seals

(2).

CAUTION

!

Replace the piston seals (1) and dust seals

(2) with new ones.

BF: Brake fluid (DOT 4)

• Install the piston seals as shown in the figure.

1

I947H1420005-01

I947H1420006-01

2

3

2

3

I947H1420007-01

I649G1420012-02

1

2

I649G1420013-02