Suzuki GSX-R1000. Service Manual - part 31

3A-6 Drive Chain / Drive Train / Drive Shaft:

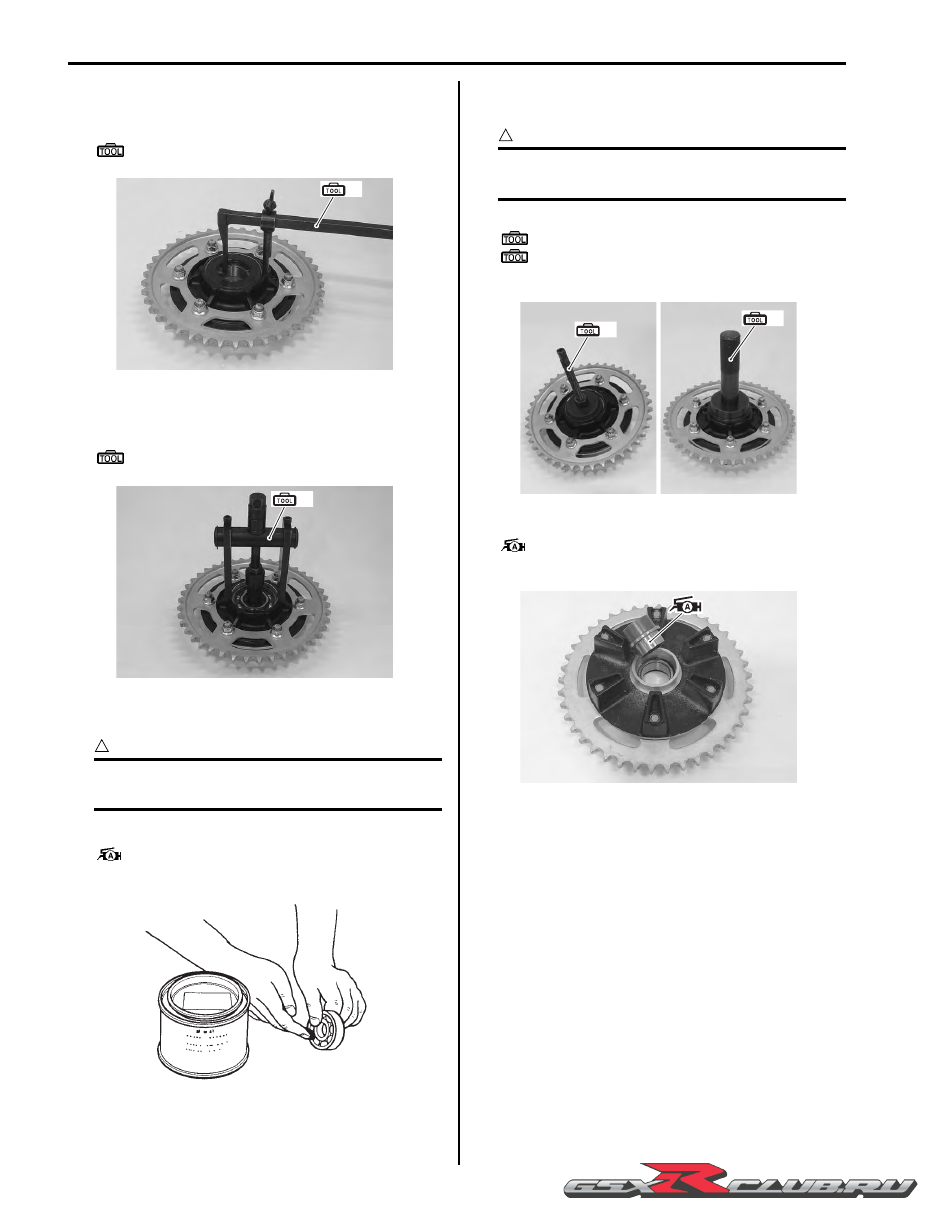

4) Remove the sprocket mounting drum dust seal with

the special tool.

Special tool

(A): 09913–50121 (Oil seal remover)

5) Remove the sprocket mounting drum bearing with

the special tool.

Special tool

(B): 09921–20240 (Bearing remover set)

Installation

CAUTION

!

The removed dust seal and bearing must be

replaced with new ones.

1) Apply grease to the bearing before installing.

: Grease 99000–25010 (SUZUKI SUPER

GREASE “A” or equivalent)

2) Install the bearing and dust seal to the sprocket

mounting drum with the special tools.

CAUTION

!

The sealed cover of the bearing must face

wheel hub side.

Special tool

(A): 09924–84510 (Bearing installer set)

(B): 09913–70210 (Bearing installing set (10

– 75

Φ

))

3) Apply grease to the retainer.

: Grease 99000–25010 (SUZUKI SUPER

GREASE “A” or equivalent)

4) Install the rear sprocket mounting drum assembly to

rear wheel hub. Refer to “Rear Sprocket / Rear

Sprocket Mounting Drum Removal and Installation”

(Page 3A-3).

5) Install the rear wheel assembly. Refer to “Rear

Wheel Assembly Removal and Installation” in

Section 2D (Page 2D-11).

(A)

I947H1310014-01

(B)

I947H1310015-01

I649G1310020-02

(A)

(B)

I947H1310016-01

I947H1310017-01