Suzuki GSX-R1000. Service Manual - part 30

2D-11 Wheels and Tires:

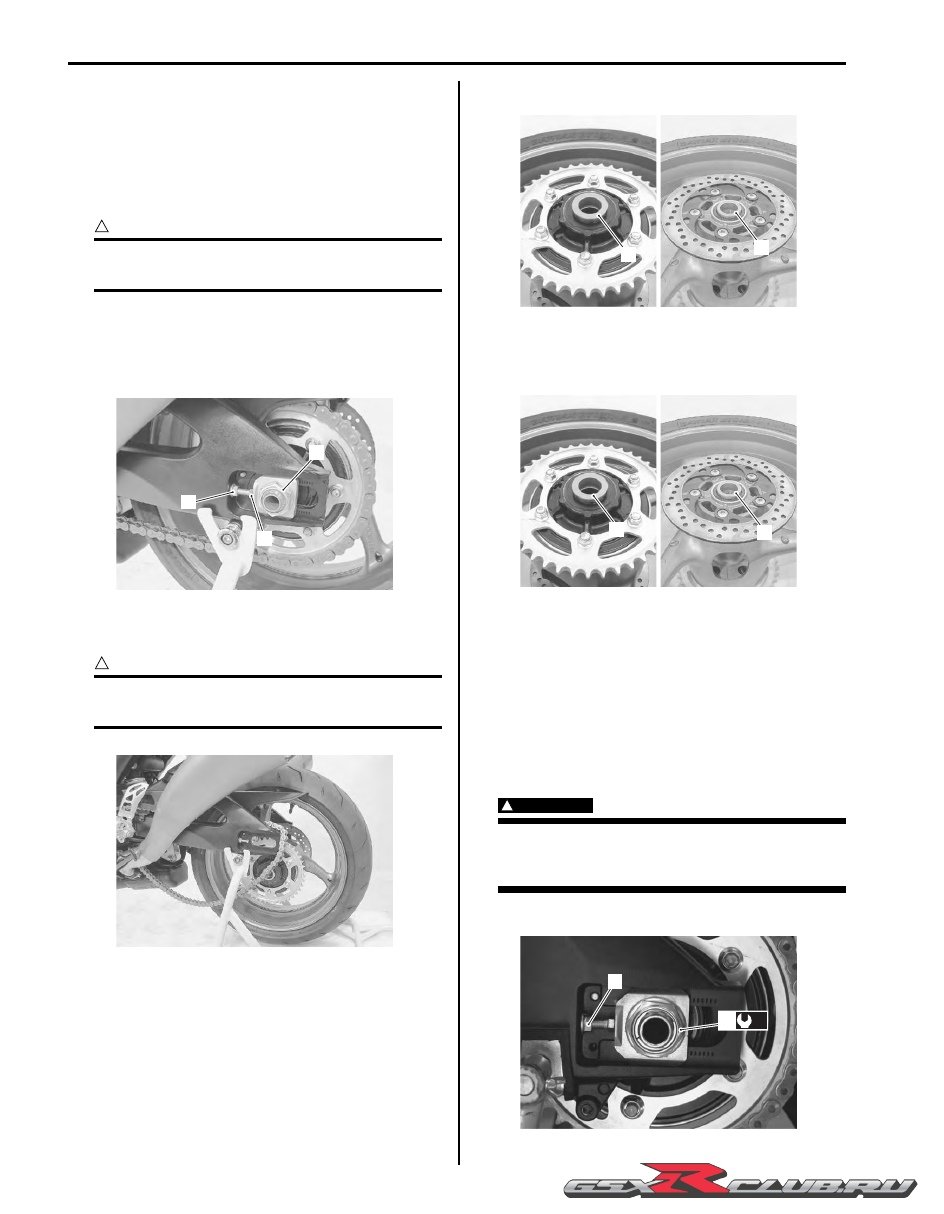

Rear Wheel Assembly Removal and Installation

B947H12406008

Removal

1) Loosen the axle nut (1).

2) Raise the rear wheel off the ground and support the

motorcycle with a jack or wooden block.

CAUTION

!

Make sure that the motorcycle is supported

securely.

3) Remove the axle nut (1).

4) Loosen the left and right lock-nuts (2) and turn in the

adjuster bolts (3).

5) Draw out the rear axle.

6) Remove the rear wheel by disengaging the drive

chain.

CAUTION

!

Do not operate the rear brake pedal with the

rear wheel removed.

7) Remove the collars (5) and (6).

Installation

1) Install the collars (1) and (2).

2) Remount the rear wheel and rear axle, tighten the

rear axle nut (3) temporarily.

3) Adjust the chain slack after installing the rear wheel.

Refer to “Drive Chain Inspection and Adjustment” in

Section 0B (Page 0B-14).

4) Tighten the rear axle nut (3) to the specified torque.

Tightening torque

Rear axle nut (a): 100 N·m (10.0 kgf-m, 72.5 lbf-

ft)

WARNING

!

After remounting the rear wheel, pump the

brake pedal several times to check for proper

brake operation.

5) Tighten both chain adjuster lock-nut (4) securely.

1

2

3

I947H1240014-02

I947H1240015-01

6

5

I947H1240017-02

2

1

I947H1240026-02

4

(a)

3

I838H1240002-01