Suzuki GSX-R1000. Service Manual - part 21

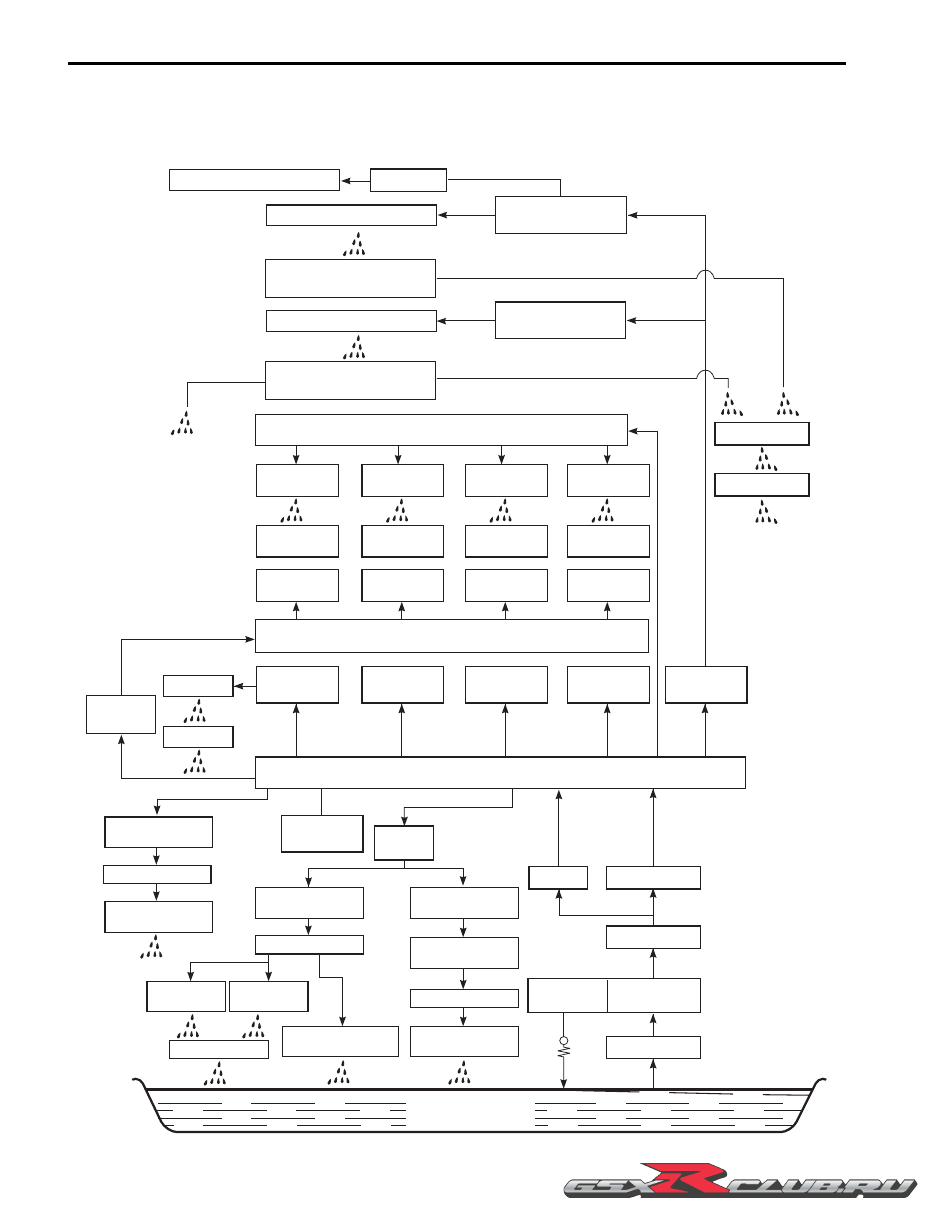

1E-2 Engine Lubrication System:

Schematic and Routing Diagram

Engine Lubrication System Chart Diagram

B947H11502001

INTAKE CAMSHAFT

INTAKE CAMSHAFT

JOURNAL HOLDER

CAM CHAIN

STARTER CLUTCH

OIL JET (#16)

CAM CHAIN TENSION ADJUSTER

#1 PISTON COOLING

OIL JET

#1 PISTON AND

CYLINDER WALL

#1 CRANK PIN

BEARING

#1 CRANKSHAFT

JOURNAL BEARING

ORIFICE

GENERATOR

GENERATOR

COVER

#2 CRANKSHAFT

JOURNAL BEARING

#3 CRANKSHAFT

JOURNAL BEARING

#4 CRANKSHAFT

JOURNAL BEARING

#5 CRANKSHAFT

JOURNAL BEARING

OIL PRESSURE

SWITCH

#2 CRANK PIN

BEARING

OIL JET

(#14)

OIL FILTER

OIL COOLER

OIL PUMP

ORIFICE

OIL STRAINER

OIL PRESSUER

REGULATOR

COUNTERSHAFT

LEFT BEARING

BALANCERSHAFT

RIGHT BEARING

COUNTERSHAFT

CLUTCH PUSH

PIECE

CLUTCH PLATES

PRIMARY DRIVEN

GEAR BEARING

COUNTERSHAFT

RIGHT BEARING

DRIVESHAFT

RIGHT BEARING

#3 CRANK PIN

BEARING

#4 CRANK PIN

BEARING

#2 PISTON AND

CYLINDER WALL

#3 PISTON AND

CYLINDER WALL

#4 PISTON AND

CYLINDER WALL

#2 PISTON COOLING

OIL JET

#3 PISTON COOLING

OIL JET

#4 PISTON COOLING

OIL JET

EXHAUST CAMSHAFT

INTAKE CAMSHAFT JOURNALS,

CAMFACES AND TAPPETS

EXHAUST CAMSHAFT JOURNALS,

CAMFACES AND TAPPETS

SUB GALLERY

MAIN GALLERY

CRANKSHAFT

OIL PAN

EXHAUST CAMSHAFT

JOURNAL HOLDER #1

BALANCERSHAFT

BALANCERSHAFT

LEFT BEARING

DRIVESHAFT

DRIVESHAFT GEARS

AND BUSHINGS

COUNTERSHAFT GEARS

AND BUSHINGS

I947H1150001-03