Suzuki GSX-R1000. Service Manual - part 22

1F-3 Engine Cooling System:

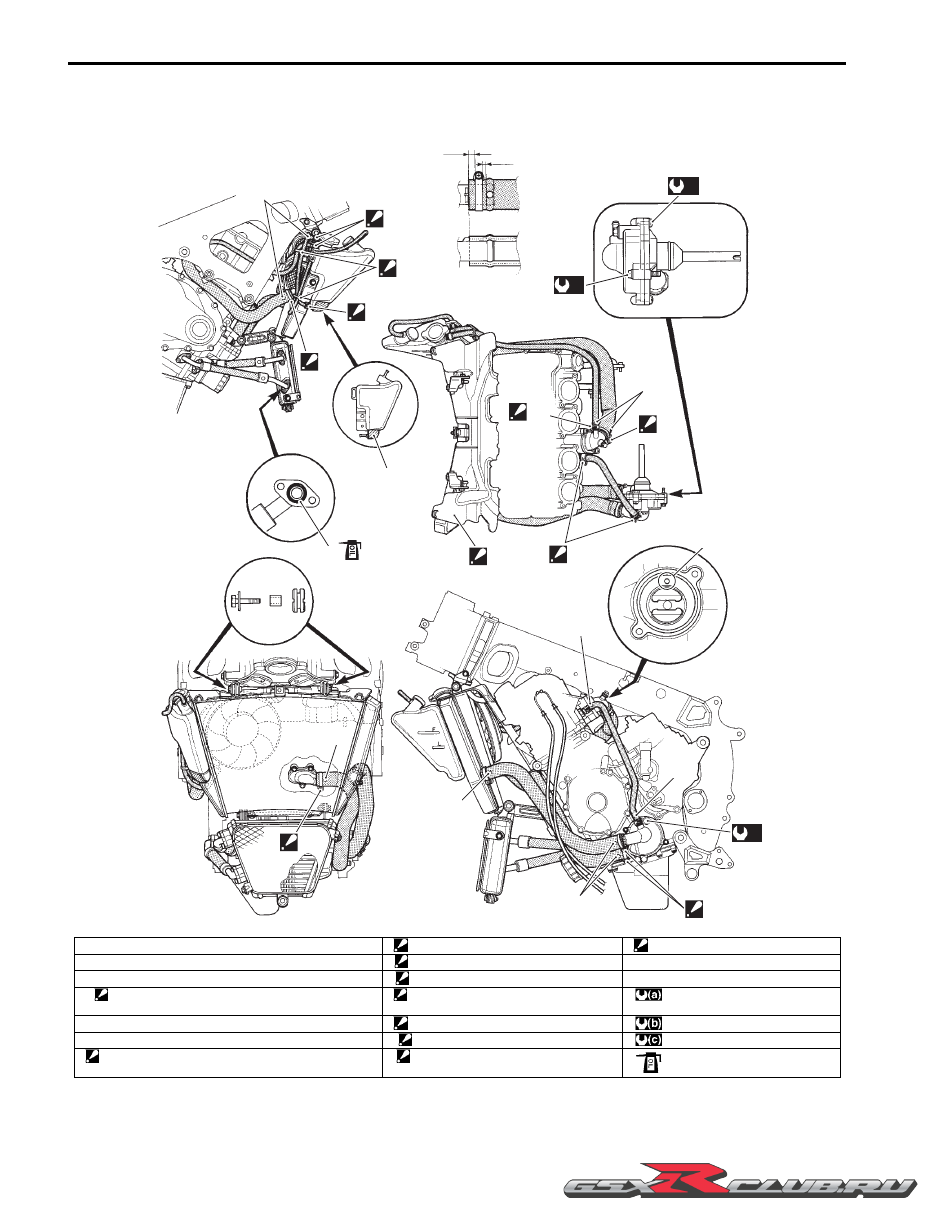

Water Hose Routing Diagram

B947H11602002

“I”

“C”

“F”

“H”

“A”

“A”

“A”

“B”

“B”

“G”

“ a ”

“ b ”

(a)

(b)

“B”

1

(c)

“K”

“A”

“J”

“D”

2

3

4

“E”

I947H1160053-03

1. Thermostat air bleeder hole

“D”: Clamp end should face right side.

“K”: Screw head should face left side.

2. Cushion

“E”: Cut off the excess tip of the clamp.

“a”: 2 – 8 mm (0.08 – 0.31 in)

3. O-ring

“F”: Screw head should face right side.

“b”: Clearance

4. Radiator heat guard

: Be careful not to damage the pawls when removing.

“G”: Screw head should face backward.

: 6 N

⋅

m (0.6 kgf-m, 4.5 lbf-ft)

“A”: Yellow marking

“H”: Clamp end should face upward.

: 10 N

⋅

m (1.0 kgf-m, 0.7 lbf-ft)

“B”: White marking

“I”: Clamp end should face left side.

: 13 N

⋅

m (1.3 kgf-m, 9.5 lbf-ft)

“C”: Clamp end should face downward.

“J”: Screw head should face forward.

: :Apply engine oil.