Suzuki GSX-R1000. Service Manual - part 18

1D-44 Engine Mechanical:

• Put on the valve spring retainer (10), and using the

special tools, press down the springs, fit the cotter

halves to the stem end, and release the lifter to allow

the cotter halves to wedge in between retainer and

stem.

CAUTION

!

• Be sure to restore each spring and valve to

their original positions.

• Be careful not to damage the valve and

valve stem when handling them.

• Be careful not to damage the tappet sliding

surface with the special tool.

Special tool

(A): 09916–14510 (Valve lifter)

(B): 09916–14522 (Valve lifter attachment)

(C): 09919–28620 (Sleeve protector)

: 09916–84511 (Tweezer)

• Be sure that the rounded lip “G” of the cotter fits

snugly into the groove “H” in the stem end.

• Install the other valves and springs in the same

manner as described previously.

• Install the tappet shims and the tappets to their

original positions.

NOTE

• Apply engine oil to the stem end, shim and

tappet before fitting them.

• When seating the tappet shim, be sure the

figure printed surface faces the tappet.

Cylinder Head Related Parts Inspection

B947H11406028

Refer to “Cylinder Head Disassembly and Assembly”

(Page 1D-40).

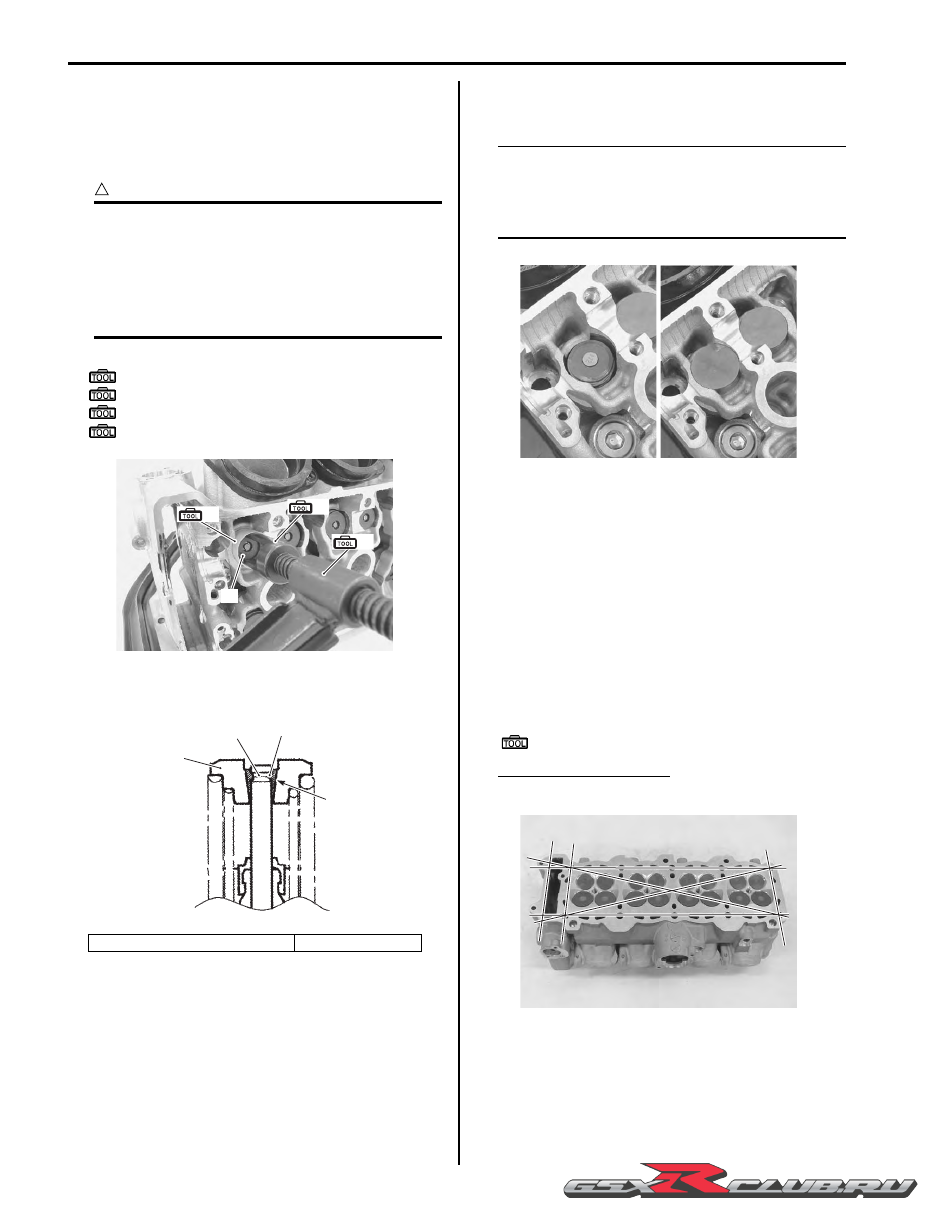

Cylinder Head Distortion

1) Decarbonize the combustion chambers.

2) Check the gasket surface of the cylinder head for

distortion. Use a straightedge and thickness gauge.

Take clearance readings at several places. If

readings exceed the service limit, replace the

cylinder head.

Special tool

: 09900–20803 (Thickness gauge)

Cylinder head distortion

Service limit: 0.02 mm (0.0008 in)

10. Valve spring retainer

11. Cotter

(A)

(B)

(C)

10

I947H1140089-01

“H”

10

11

“G”

I947H1140090-02

I947H1140091-01

I947H1140092-02