Suzuki GSX-R1000. Service Manual - part 16

1D-12 Engine Mechanical:

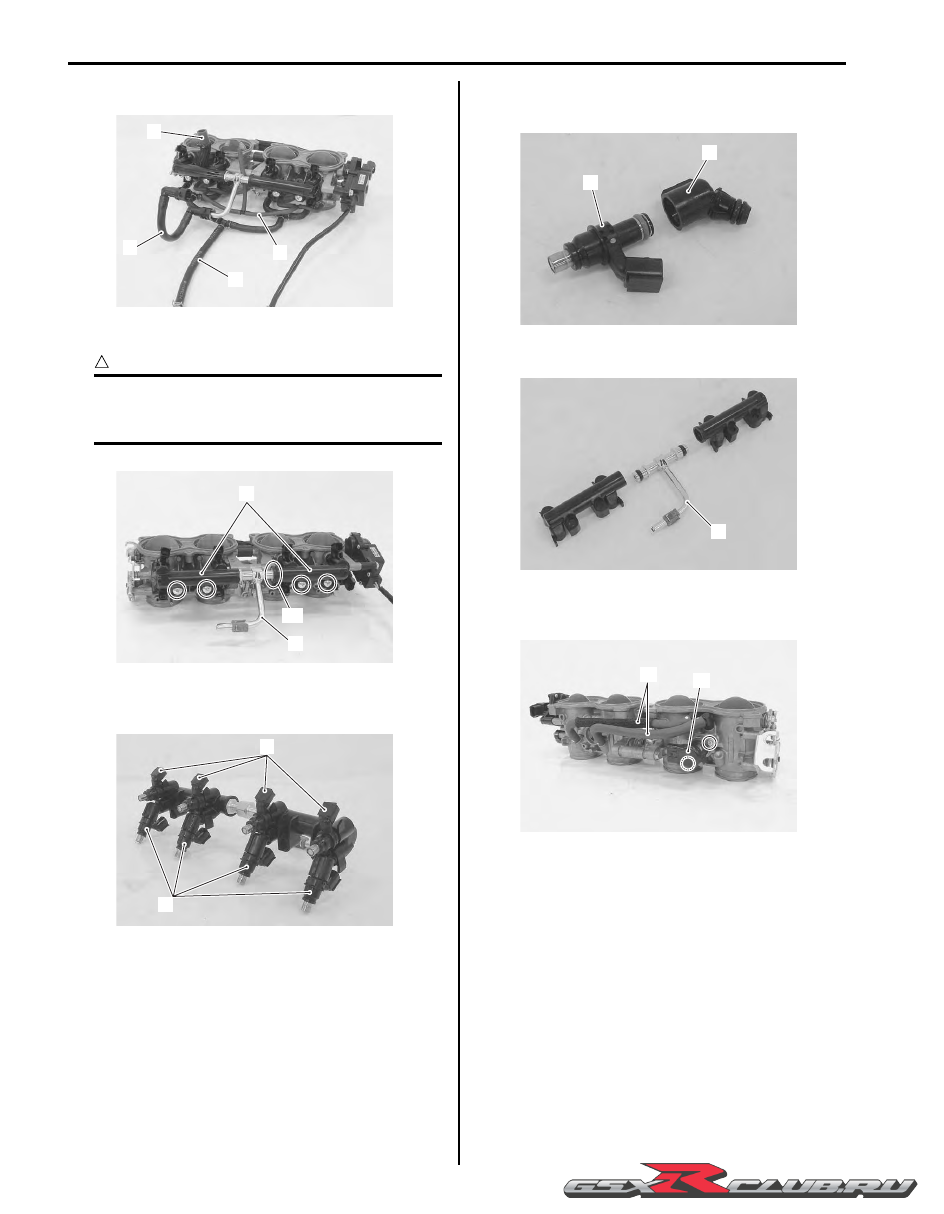

2) Disconnect the purge hose (4). (E-33 only)

3) Remove the fuel delivery pipe assembly (5).

CAUTION

!

Be careful not to twist the fuel delivery pipes

and T-joint (6) when removing them, or joint

part “A” of the fuel delivery pipe get damage.

4) Remove the primary fuel injectors (7) and secondary

fuel injectors (8) from the fuel delivery pipes.

5) Remove the fuel pipe (9) from the primary fuel

injectors (7).

6) Remove the T-joint (6) from the fuel delivery pipes.

7) Remove the ISC valve hoses (10) and ISC valve

(11).

1

2

3

4

I947H1140299-01

5

6

“A”

I947H1140008-01

7

8

I947H1140009-01

7

9

I947H1140010-01

6

I947H1140011-01

11

10

I947H1140012-01