Suzuki GSX-R1000. Service Manual - part 7

1A-34 Engine General Information and Diagnosis:

Step

Action

Yes

No

1

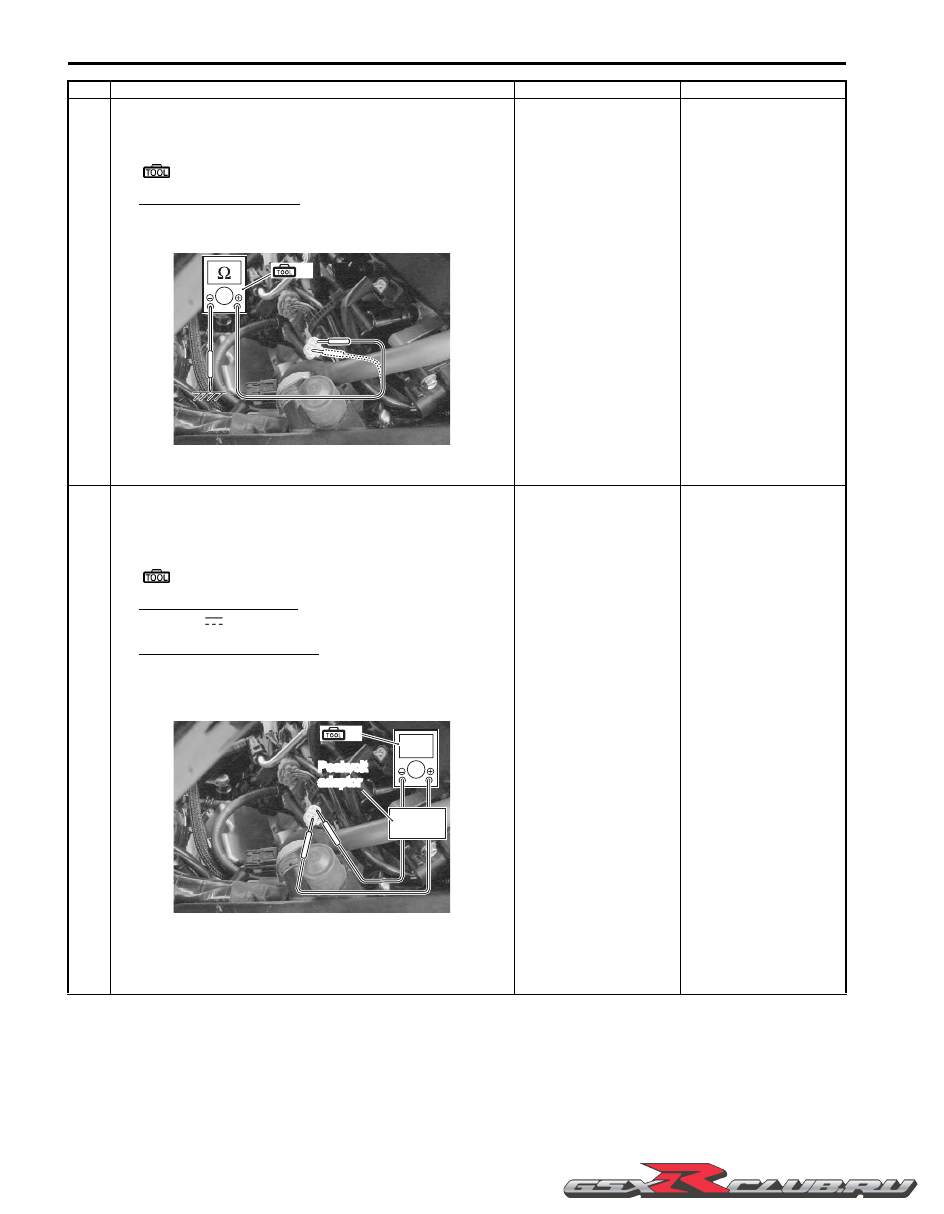

5) If OK, then check the continuity between each terminal

and ground.

Special tool

(A): 09900–25008 (Multi circuit tester set)

CKP sensor continuity

∞

Ω

(Infinity) (B – Ground, Bl/Y– Ground)

Are the resistance and continuity OK?

Go to Step 2.

Replace the CKP

sensor with a new one.

2

1) Crank the engine several seconds with the starter motor,

and measure the CKP sensor peak voltage at the

coupler.

Special tool

(A): 09900–25008 (Multi circuit tester set)

Tester knob indication

Voltage (

)

CKP sensor peak voltage

0.5 V and more

((+) terminal: B – (–) terminal: Bl/Y)

2) Repeat the 1) test procedures several times and

measure the highest peak voltage.

Is the voltage OK?

• B or Bl/Y wire of the

harness side open or

shorted to ground.

• Loose or poor

contacts on the CKP

sensor coupler or

ECM coupler

(Terminal “9” or “21”).

• If the wires and

connection are OK,

intermittent trouble or

faulty ECM.

• Recheck each

terminal and wire

harness for open

circuit and poor

connection.

• Replace the ECM

with a known good

one, and inspect it

again. Refer to “ECM

Removal and

Installation” in

Section 1C

(Page 1C-1).

• Inspect that metal

particles or foreign

material stuck on the

CKP sensor and rotor

tip.

• If there are no metal

particles and foreign

material, then replace

the CKP sensor with

a new one. Refer to

“CKP Sensor

Removal and

Installation” in

Section 1C

(Page 1C-2).

(A)

I947H1110014-01

V

Peakvolt

adaptor

(A)

I947H1110015-01