Suzuki GSX-R1000. Service Manual - part 8

1A-50 Engine General Information and Diagnosis:

DTC “C15” (P0115-H/L): ECT Sensor Circuit Malfunction

B947H11104014

Detected Condition and Possible Cause

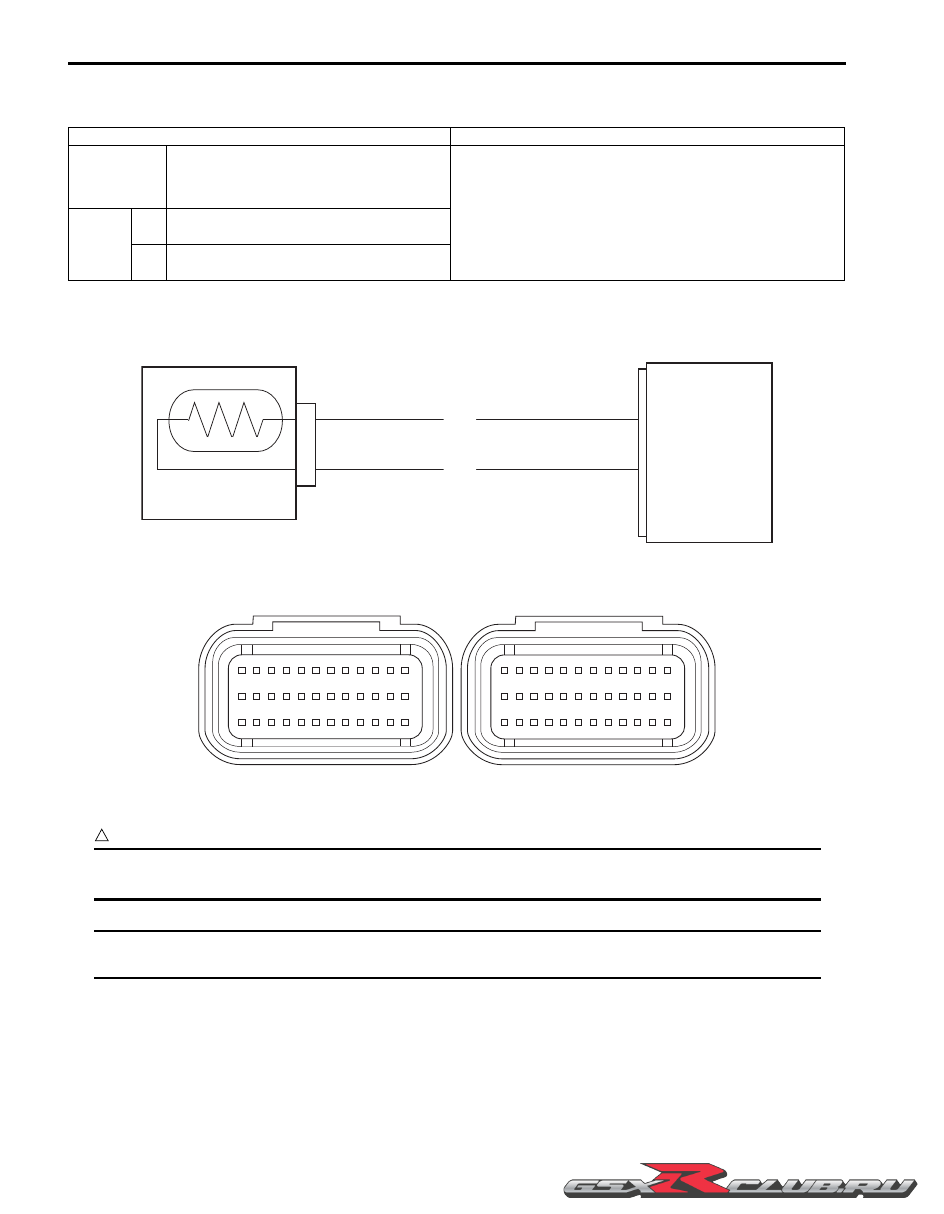

Wiring Diagram

ECM coupler (Harness side)

Troubleshooting

CAUTION

!

When using the multi-circuit tester, do not strongly touch the terminal of the ECM coupler with a

needle pointed tester probe to prevent terminal damage.

NOTE

After repairing the trouble, clear the DTC using SDS tool. Refer to “Use of SDS Diagnosis Reset

Procedures” (Page 1A-14).

Detected Condition

Possible Cause

C15

Output voltage is not with in the following

range.

0.15 V

≤

Sensor voltage < 4.85 V

• ECT sensor circuit open or short.

• ECT sensor malfunction.

• ECM malfunction.

P0115

H

Sensor voltage is higher than specified

value.

• ECT sensor circuit is open or ground circuit open.

L

Sensor voltage is lower than specified

value.

• ECT sensor circuit shorted to ground.

ECM

E2

ECTS

B/Br

ECT sensor

B/BI

32

35

I837H1110027-01

1

2

3

4

5

6

7

8

9 10 11 12

13 14 15 16 17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32 33 34 35 36

37 38 39 40 41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56 57 58 59 60

61 62 63 64 65 66 67 68 69 70 71 72

I837H1110007-02