Hyundai Excavator R210LC-7. Service and repair manual - page 27

8-5

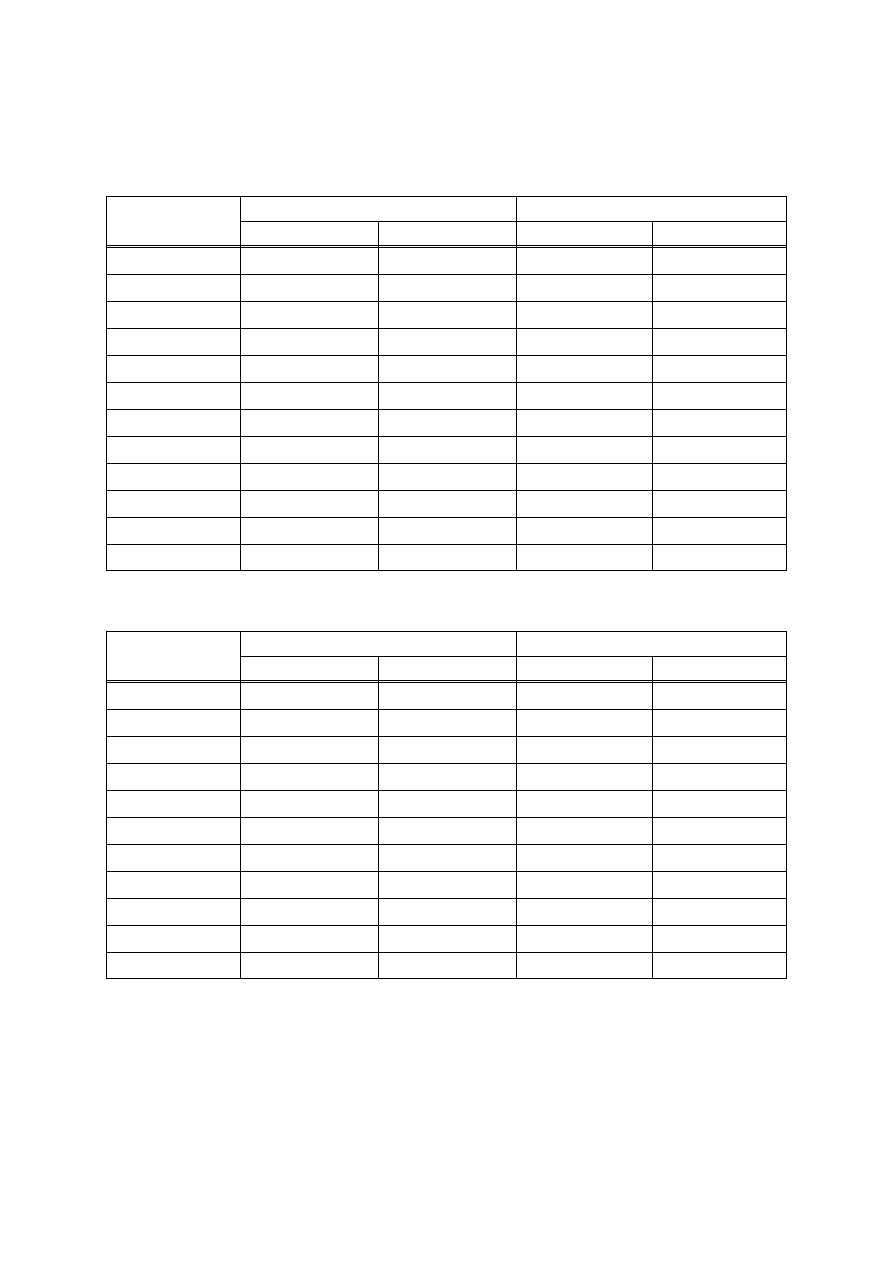

2. TORQUE CHART

Use following table for unspecified torque.

BOLT AND NUT - Coarse thread

1)

Bolt size

M 6

1.0

M 8

1.25

M10

1.5

M12

1.75

M14

2.0

M16

2.0

M18

2.5

M20

2.5

M22

2.5

M24

3.0

M30

3.5

M36

4.0

0.85 ~ 1.25

2.0 ~ 3.0

4.0 ~ 6.0

7.4 ~ 11.2

12.2 ~ 16.6

18.6 ~ 25.2

25.8 ~ 35.0

36.2 ~ 49.0

48.3 ~ 63.3

62.5 ~ 84.5

124 ~ 168

174 ~ 236

lbf ft

6.15 ~ 9.04

14.5 ~ 21.7

28.9 ~ 43.4

53.5 ~ 79.5

88.2 ~ 120

135 ~ 182

187 ~ 253

262 ~ 354

350 ~ 457

452 ~ 611

898 ~ 1214

1261 ~ 1703

kgf m

1.14 ~ 1.74

2.73 ~ 4.12

5.5 ~ 8.3

9.8 ~ 15.8

16.7 ~ 22.5

25.2 ~ 34.2

35.1 ~ 47.5

49.2 ~ 66.6

65.8 ~ 98.0

85.0 ~ 115

169 ~ 229

250 ~ 310

lbf ft

8.2 ~ 12.6

19.7 ~ 29.8

39.8 ~ 60

71 ~ 114

121 ~ 167

182 ~ 247

254 ~ 343

356 ~ 482

476 ~ 709

615 ~ 832

1223 ~ 1655

1808 ~ 2242

8T

10T

BOLT AND NUT - Fine thread

2)

Bolt size

M 8

1.0

M10

1.25

M12

1.25

M14

1.5

M16

1.5

M18

1.5

M20

1.5

M22

1.5

M24

2.0

M30

2.0

M36

3.0

kgf m

2.17 ~ 3.37

4.46 ~ 6.66

7.78 ~ 11.58

13.3 ~ 18.1

19.9 ~ 26.9

28.6 ~ 43.6

40.0 ~ 54.0

52.7 ~ 71.3

67.9 ~ 91.9

137 ~ 185

192 ~ 260

lbf ft

15.7 ~ 24.3

32.3 ~ 48.2

76.3 ~ 83.7

96.2 ~ 130

144 ~ 194

207 ~ 315

289 ~ 390

381 ~ 515

491 ~ 664

990 ~ 1338

1389 ~ 1879

kgf m

3.04 ~ 4.44

5.93 ~ 8.93

10.6 ~ 16.0

17.9 ~ 24.1

26.6 ~ 36.0

38.4 ~ 52.0

53.4 ~ 72.2

70.7 ~ 95.7

90.9 ~ 123

182 ~ 248

262 ~ 354

lbf ft

22.0 ~ 32.0

42.9 ~ 64.6

76.6 ~ 115

130 ~ 174

193 ~ 260

278 ~ 376

386 ~ 522

512 ~ 692

658 ~ 890

1314 ~ 1795

1893 ~ 2561

8T

10T

kgf m