KTM LC4 400-660LC42003 engine. Manual - part 26

Repair manual KTM LC4

Art.-Nr

. 3.206.006 -E

10-5D

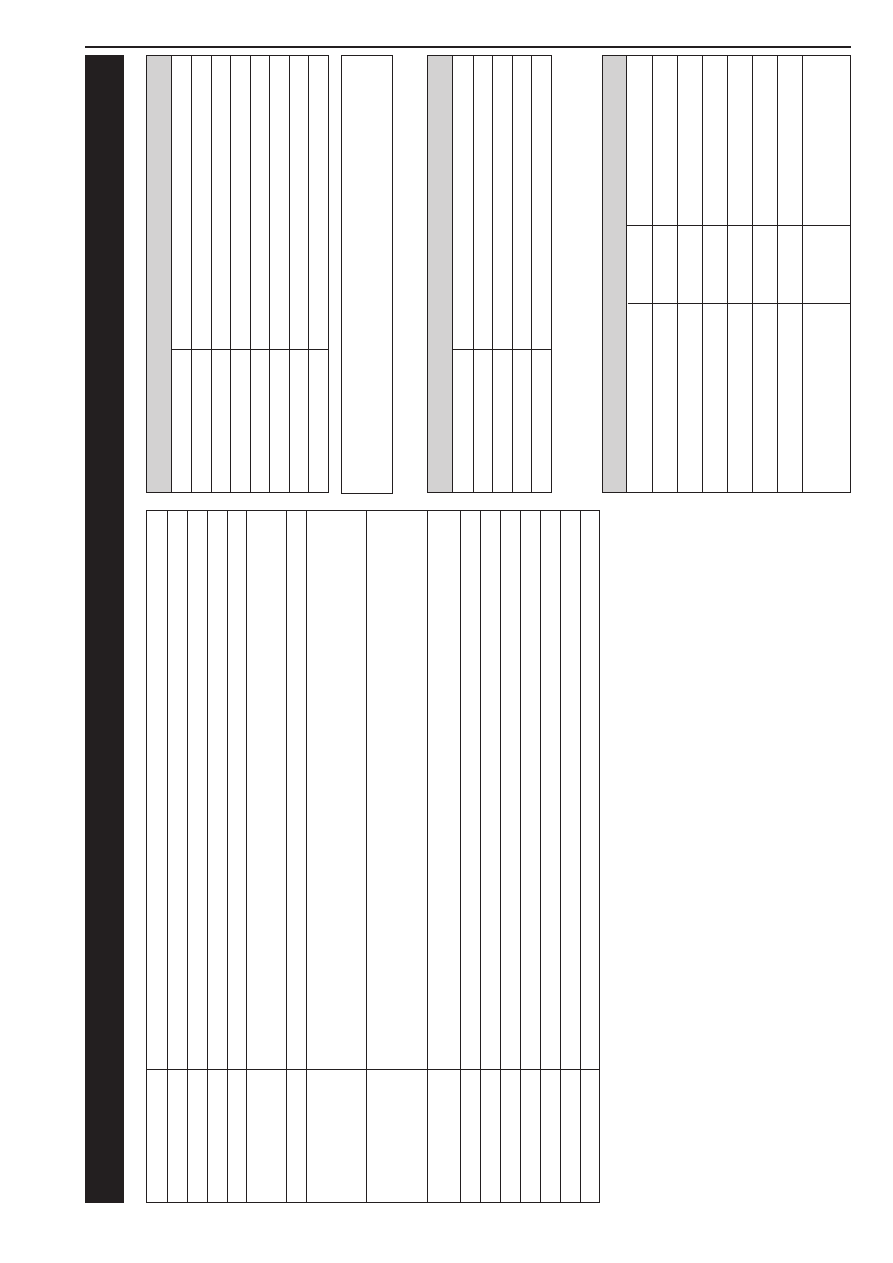

TECHNICAL SPECIFICA

TIONS - CHASSIS 400/540 SXC ‘98

400

/540 SXC

Frame

Central chr

ome-moly-steel frame

Fork

WP

Extr

eme

Wheel travel fr

ont/r

ear

285/320 mm (11,2/12,6 in)

Rear suspension

Central shock absorber (WP)

with PRO-LEVER linkage to r

ear

-swingarm with needle bearing

Fr

ont brake

Disc brake with carbon-steel brake disc , brake caliper floated

brake disc

Ø

= 260 mm (10,2 in)

Rear brake

Disc brake with carbon-steel brake disc

Ø

220 mm (8,7 in), brake caliper floated

Ty

re

sf

ront

90/90

- 2

1

Air pr

essur

e of

fr

oad

1,0 bar (14 psi)

Air pr

ess. r

oad, driver only

1,5 bar (21 psi)

Air pr

ess. r

oad with passenger

–

Ty

res r

ear

140/80

- 1

8

Air pr

essur

e of

fr

oad

1,2 bar (17 psi)

Air pr

ess. r

oad, driver only

2,0 bar (28 psi)

Air pr

ess. r

oad with passenger

–

Fuel tank capacity

9 liter (3 US

gallons)

of that 1,5 liter (0,4 US

gallons) r

eserve

Final drive ratio

400: 14:50 540:15:50

Chain

5

/

8

x

1

/

4

" O-Ring

Steering angle

62,5°

Wheel base

15

10

±

10

mm (59,4

±

0,4 in)

Seat high

940 mm (37 in)

Gr

ound clearance

350 mm (13,8 in)

Dead weight without fuel

400: 121 kg (267 lbs) 540: 122 kg (269 lbs)

Collar bolt fr

ont axle

M 1

0

40 Nm

(30 ft.lb)

Brake caliper fr

ont

M 8

Loctite 243 + 25 Nm

(18 ft.lb)

Collar nut r

ear axle

M 20x1

,5

80 Nm

(59 ft.lb)

Hex. nut swing arm bolt

M 1

4

x1

,5

100 Nm

(74 ft.lb)

Clamping bolt top triple clamp

M 8

15 Nm

(11 ft.lb)

Clamping bolt bottom triple clamp

M 8

20 Nm

(15 ft.lb)

Clamping bolts fork leg axle passage

M 8

10 Nm

(7,4 ft.lb)

Other bolts chassis

M 6

10 Nm

(7,4 ft.lb)

M 8

25 Nm

(18 ft.lb)

M 10

45 Nm

(33 ft.lb)

TORQUES

WP 09.18.S7.44

Compr

ession adjuster

12

Rebound adjuster

12

Spring

4,2 N/mm

Spring pr

eload

7 mm

Air chamber length

155 mm

Capacity per fork leg

ca 800 ccm

Fork oil

SAE 5

ST

ANDARD ADJUSTMENT - FORK

NOTE FOR WHITE POWER FORKS:

The damping units in the left and the right fork leg ar

e of dif

fer

ent design. Make

sur

e not to mix them up in case of r

epair or service works.

WP 01.18.Q7.82

Compr

ession adjuster

3

Rebound adjuster

4

Spring

63/260

Spring pr

eload

23 mm

ST

ANDARD-ADJUSTMENT - SHOCK ABSORBER