KTM LC4 400-660LC42003 engine. Manual - part 25

9-7D

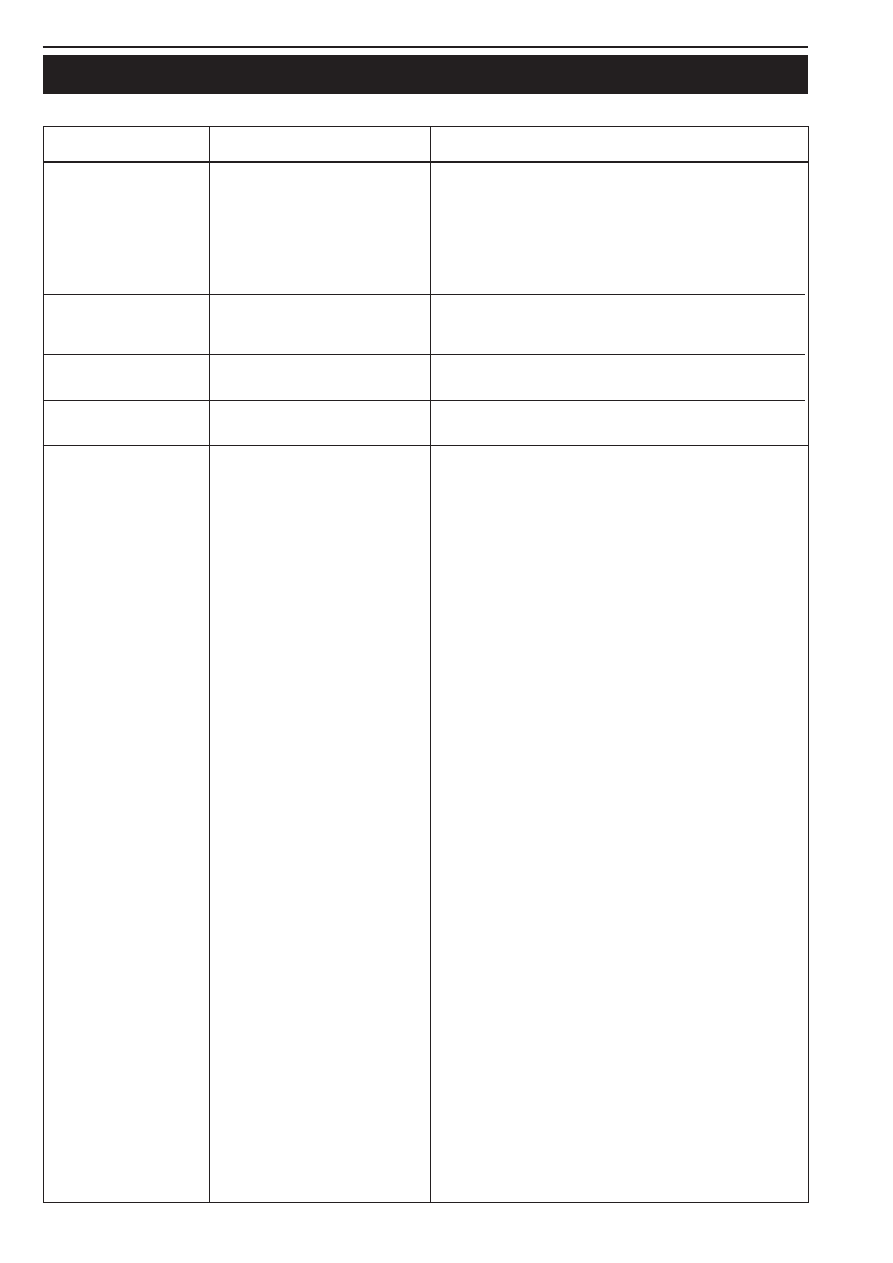

TROUBLE SHOOTING LC4

TROUBLE

Engine doesn’t crank.

The engine doesn't crank.

The neutral indicator

lamp doesn't light up.

The engine cranks only

with pulled clutch lever

Engine cranks with gear

engaged.

Engine cranks but doesn’t

start.

CAUSE

Operating errror

Discharged battery.

Defect ignition lock or emergency

OFF switch

Blown fuse safe-starting system.

Blown main fuse.

Defect safe-starting system.

Defect safe-starting system.

Operating error

The motorcycle has been out of

operation for a longer period of

time. Therefore old fuel has

accumulated in the float chamber

Fuel supply interrupted

Flooded engine

Sooty or wet spark plug

Electrode gap too large

Spark plug connector or spark plug

faulty

The plug connection of the CDI-

unit, the pulse generator or the

ignition coil has oxydized

Water in carburetor or jets blocked

REMEDY

Turn on the ignition, switch the gear to neutral and switch

the emergency OFF switch on.

Recharge the battery and investigate the causes for

discharging.

Check ignition lock and emergency OFF switch.

Replace fuse (below the headlight mask).

Remove seat and replace the main fuse.

Check the components of the safe-starting system.

Check the components of the safe-starting system.

Open fuel tap, tank fuel, you did not use choke i.e. the

warmstart device. Pay attention to starting off information

(see driving instructions).

The easily inflammable components of the new fuels

evaporate during longer periods of standstill.

When the motorcycle has been out of operation for more

than a week, it is therefore recommended to drain the old

fuel from the float chamber. The engine will immediately start

off when the float chamber is filled with new fuel.

Loosen fuel hose at carburettor, lead into a basin and open

fuel tap

– if fuel leaks out, the carburetor might need cleaning

– if no fuel leaks out, check tank ventilation, i.e. clean fuel tap

Fully open the throttle when starting or exchange the spark

plug, respectively

Clean and dry the spark plug or exchange it, respectively

Adjust spark plug electrode gap to 0,7 mm

Dismount spark plug, connect ignition cable, hold to ground

(blank place on engine) and actuate starter, a strong spark

must be produced at the spark plug

– If no spark is created exchange the spark plug.

– If the new spark plug doesn't produce a spark either,

disconnect the spark plug connector from the ignition cable,

hold it a distance of approx. 5 mm from ground and start.

– If a spark now occurs, replace spark plug cap

– If no spark is produced, control ignition system

Remove the seat, the right side cover and the fuel tank.

Clean the plug connection and treat it with contact spray

Dismount and clean carburetor