KTM LC4 400-660LC42003 engine. Manual - part 24

8-48D

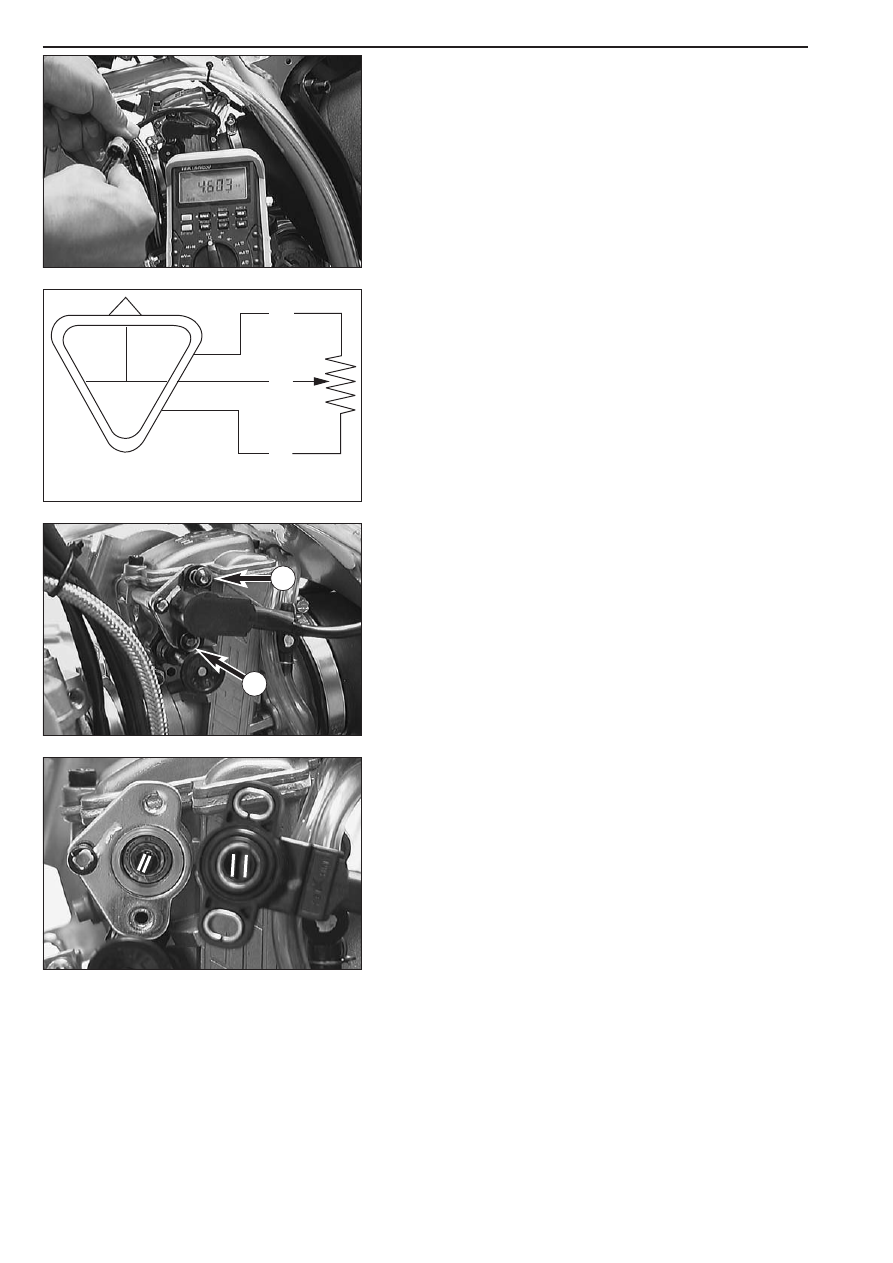

Checking the throttle valve sensor

NOTE: The following measurement must be taken at a component

temperature of approx. 20°C.

– Open the plug-and-socket connection of the throttle valve sensor.

– Connect a multimeter (measuring range Ω x 1k) to the blue (+) and

the black (-) cable of the throttle valve sensor.

Resistance of throttle valve sensor: 4 - 6 kΩ

– Now, connect the multimeter to the yellow (+) and the black (-)

cable of the throttle valve sensor.

– As you open the throttle grip slowly, the resistance must change

evenly.

Resistance of throttle valve sensor: 0-5 kΩ ±1 kΩ

(while opening the throttle grip)

Dismounting and installing the throttle valve sensor

– Disconnect the plug-and-socket connection of the throttle valve

sensor and remove the bolts

1

.

– Take the throttle valve sensor off the carburetor.

– When mounting the throttle valve sensor, make sure that the flat

spot at the throttle valve pin engages the groove on the throttle

valve sensor.

– Mount the 2 bolts, however, do not yet tighten them fully and adjust

the position of the throttle valve sensor. Secure the 2 bolts with

Loctite 243.

bl

bl

ge

ge

s

s

bl = blue

ge = yellow

s = black

1

1