Suzuki Grand Vitara JB416 / JB420. Manual - part 383

9E-5 Glass / Windows / Mirrors:

Repair Instructions

Windshield Removal and Installation

S5JB0A9506001

Removal

1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Remove windshield side garnish.

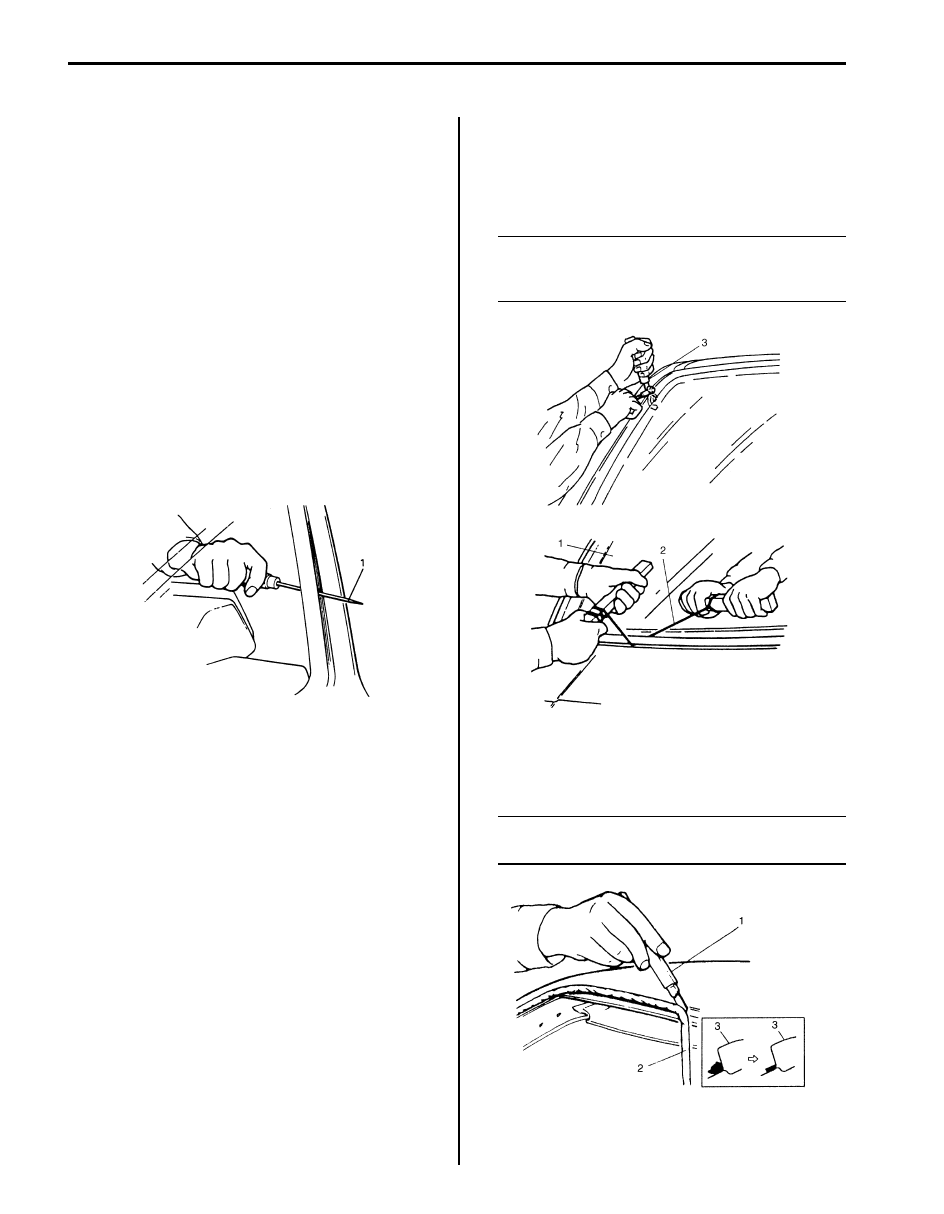

4) Using tape, cover body surface around glass to

prevent any damage.

5) Remove rear view mirror, sun visor and front pillar

trims (right & left).

6) If necessary, remove instrument panel. Refer to

“Instrument Panel Removal and Installation in

Section 9C”.

7) If necessary, remove head lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

8) Remove (or cut) windshield molding.

9) Drill hole with eyeleteer (1) through adhesive and let

piano string through it.

10) Cut adhesive all around windshield (1) with piano

string (2). When using tool, windshield knife (3), to

cut adhesive, be careful not to cause damage to

windshield. Use wire to cut adhesive along lower

part of windshield.

NOTE

Use piano string (2) as close to glass as

possible so as to prevent damage to body

and instrument panel.

11) Using knife (1), smoothen adhesive (2) remaining on

body side (3) so that it is 1 – 2 mm (0.039 – 0.078

in.) thick all around.

NOTE

Before using knife (1), clean it with alcohol or

the like to remove oil from it.

I2RH01950040-01

I3RH0A950006-01

I2RH01950042-01