Dacia Solenza (engine E7J). Manual - part 43

IGNITION AND INJECTION

17

17 - 78

PR004

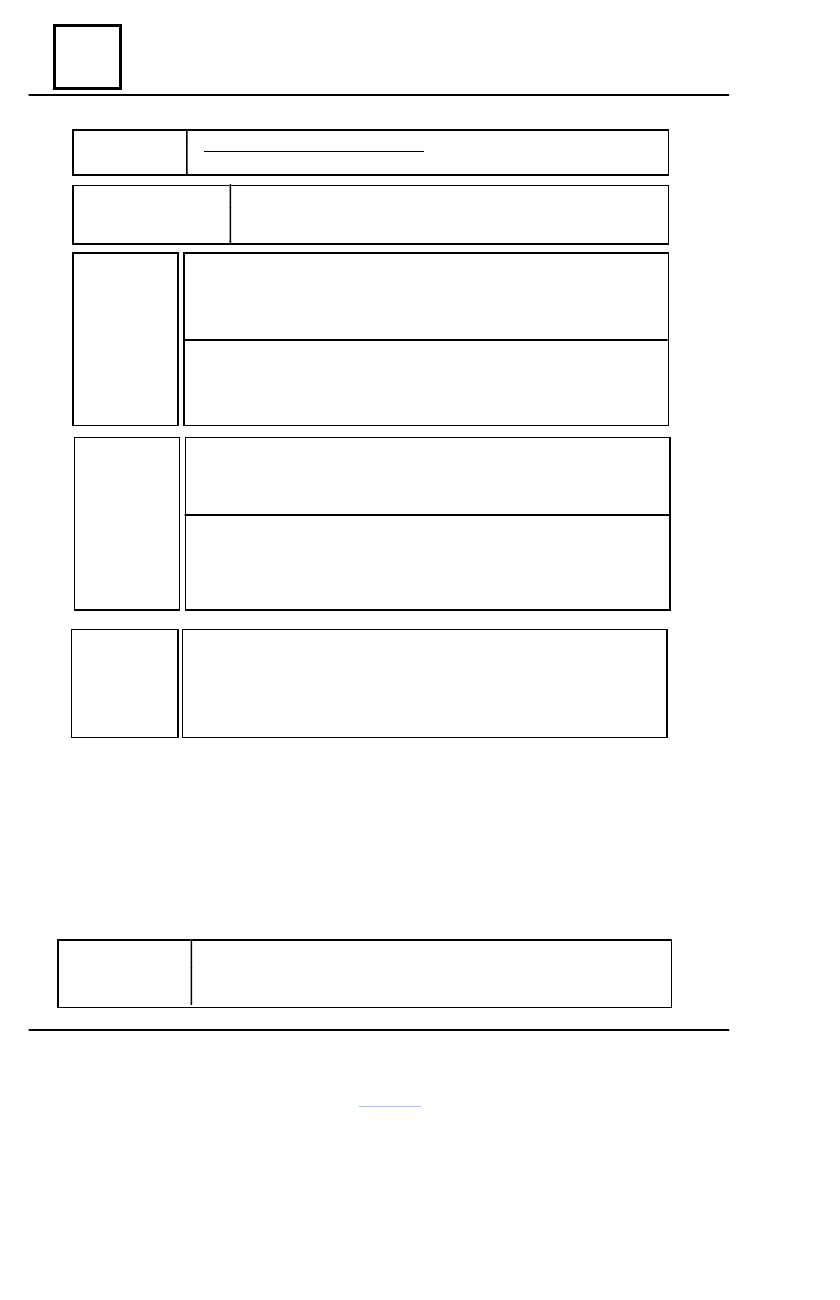

COMPUTER

SUPPLYING VOLTAGE

RECOMMEN

DATIONS

No failure must be present or memorized.

No consumers

If voltage > Min, the battery is discharged :

Check that charging voltage is correct with and without consumers.

Under contact

If voltage > Max, the battery i

s, probably, too charged:

Check that charging voltage is correct with and without consumers.

If voltage < Min, the charging voltage is to weak :

Check that charging circuit in order to detect the origin of this problem.

At idling

If voltage > Max, t he char

ging voltage is too strong:

The alternator-charging regulator is damaged.

Fix this problem and check the electrolyte level in the battery.

If the battery

and the charging

The problem must be treated using the DF345 diagnostic method : Supply +5

circuit are

volts potentiometers and sensors

correct.

AFTER

Restart the conformity checking from the beginning.

REPARATION

Diagnostic – Parameters interpretation