Mazda 6. Manual - part 181

CHARGING SYSTEM

G–7

G

GENERATOR INSPECTION

A6E471018300W02

Generator Warning Light

1. Verify that the battery is fully charged.

• Charge if necessary.

2. Verify that the drive belt deflection/tension is correct. (See

• If not as specified, replace the drive belt.

3. Turn the ignition switch to ON and verify that the generator warning light illuminates.

• If not as specified, inspect the generator warning light.

4. Verify that the generator warning light turns off after the engine is started.

• If not specifed, inspect if any of the DTCs are displayed: P0112, P0113, P2502, P2503, P2504.

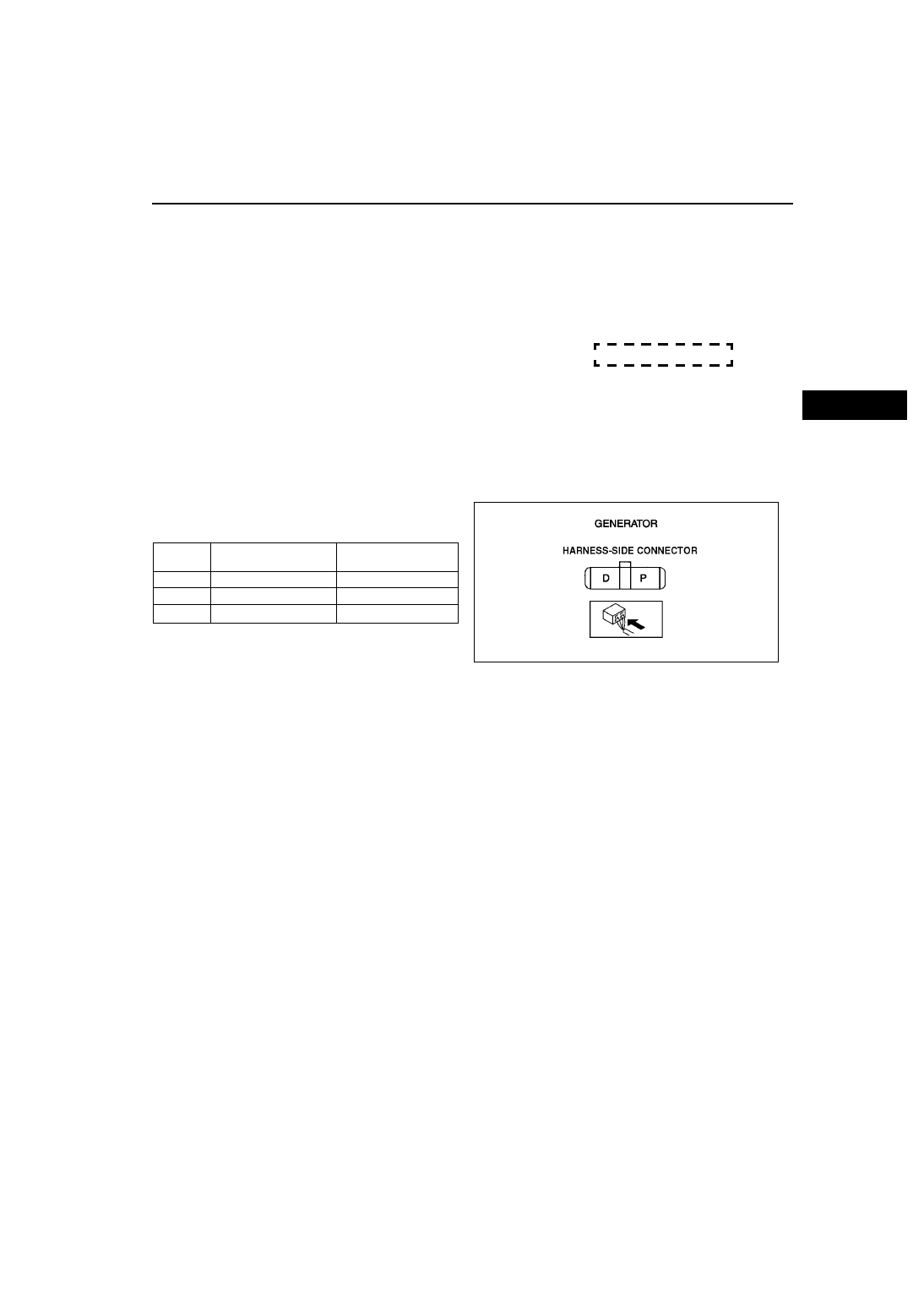

Generator

Voltage

1. Verify that the battery is fully charged.

2. Verify that the drive belt deflection/tension is correct. (See

• If not as specified, replace the drive belt.

3. Turn off all electrical loads.

4. Turn the engine switch to start the engine and verify that the generator rotates smoothly without any noise while

the engine is running.

5. Measure the voltage at the terminals shown in the table.

• If not as specified, repair or replace the

generator as necessary.

Standard voltage

*

: Turn the following electrical loads on and verify that

the voltage reading increases.

— Headlights

— Blower motor

— Rear window defroster

Current

1. Verify that the battery is fully charged.

• If the battery is not fully charged, charge the battery.

2. Verify that the drive belt deflection/tension is correct. (See

• If not as specified, replace the drive belt.

3. Disconnect the negative battery cable.

4. Connect an ammeter, capable of reading 120 A or above, between generator terminal B and the wiring

harness.

5. Connect the negative battery cable.

6. Turn off all electrical loards.

7. Start the engine and increase the engine speed to 2,000—2,500 rpm.

8. Turn the following electrical loads on and verify that the current reading increases.

• Headlights

• Blower motor

• Rear window defroster

— If generator terminal B current will not increase, repair or replace the generator as necessary.

Note

• Current required for generating power varies with electrical loads applied.

Terminal Ignition switch ON (V)

Idle (V)

[20

°C {68 °F}]

B

B+

13—15

P

Approx. 1

Approx. 3—8

D

Approx. 0

*

A6E4710W003