Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 959

7C–6

CLUTCH

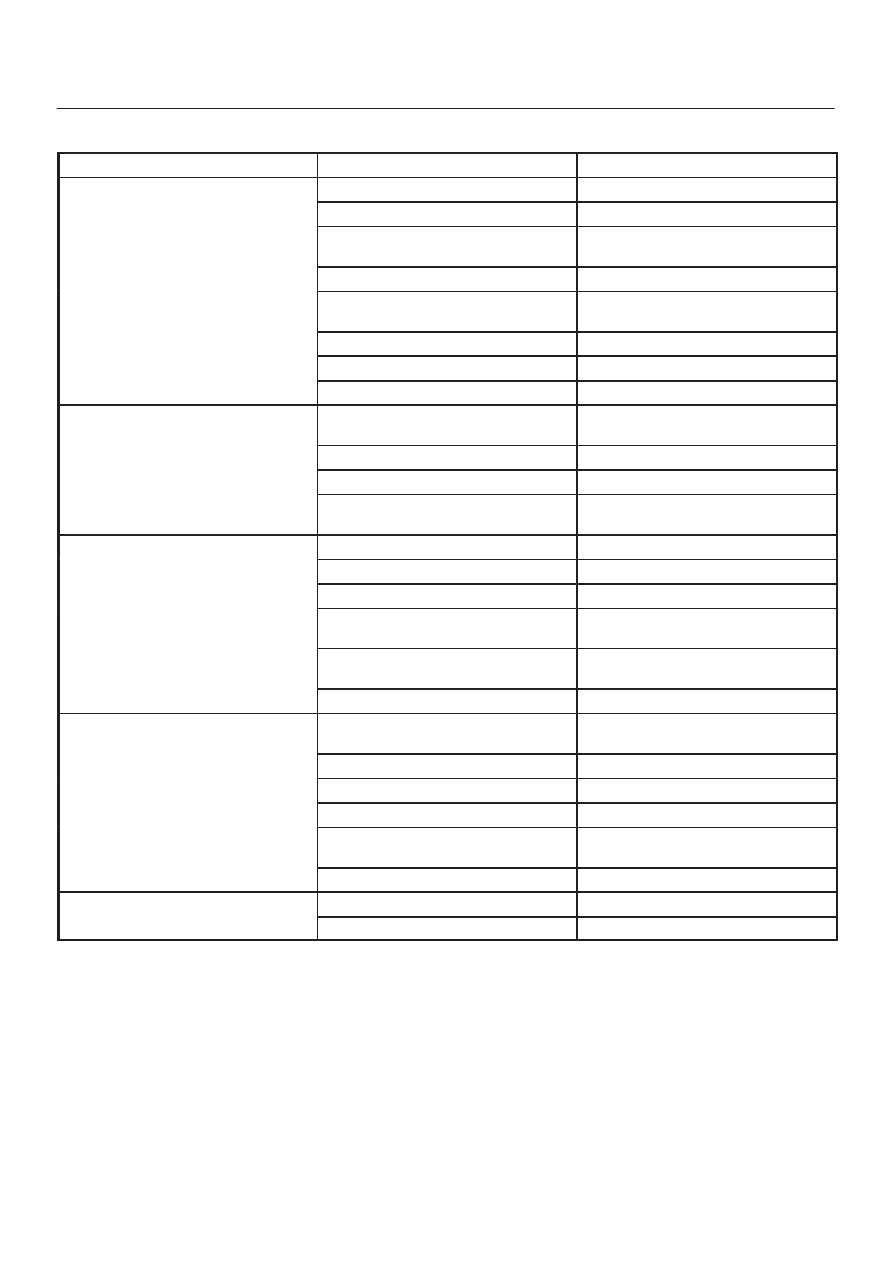

Diagnosis

Condition

Possible cause

Correction

Dragging

Fluid leakage.

Repair

Air in hydraulic line.

Bleed

Master cylinder and slave cylinder

seals worn.

Replace seals.

Driven plate warped.

Replace driven plate.

Diaphragm spring weakened or tip of

fingers worn.

Replace pressure plate

Driven plate sticking on splines.

Lubricate with grease or replace.

Clutch spline worn.

Repair

Release bearing worn or damaged.

Replace release bearing.

Slipping

Driven plate facing worn or oil

soaked.

Replace driven plate and check for

leaks.

Diaphragm spring weakened.

Replace pressure plate.

Pressure plate or flywheel warped.

Correct or replace.

Master cylinder and slave cylinder

seals worn.

Replace seals.

Chattering

Engine mounts loose or damaged.

Tighten or replace.

Driven plate facing warped.

Replace driven plate.

Surface of facing hardened.

Replace driven plate

Driven plate facing oil soaked.

Replace driven plate and check for

leaks.

Damper springs weakened or

broken.

Replace.

Pressure plate or flywheel warped.

Correct or replace.

Noisy

Replace bearing binding.

Correct, or replace if damaged, and

lubricate.

Replace bearing worn or damaged.

Replace release bearing.

Release bearing poorly lubricated.

Lubricate.

Pilot bearing worn.

Replace pilot bearing.

Damper springs weakened or

broken.

Replace driven plate.

Rivets of driven plate exposed.

Replace driven plate.

Replace driven plate.

Hydraulic line blocked.

Clean out or replace.

Master or slave cylinders binding.

Repair or replace as needed.