Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 960

7C–10

CLUTCH

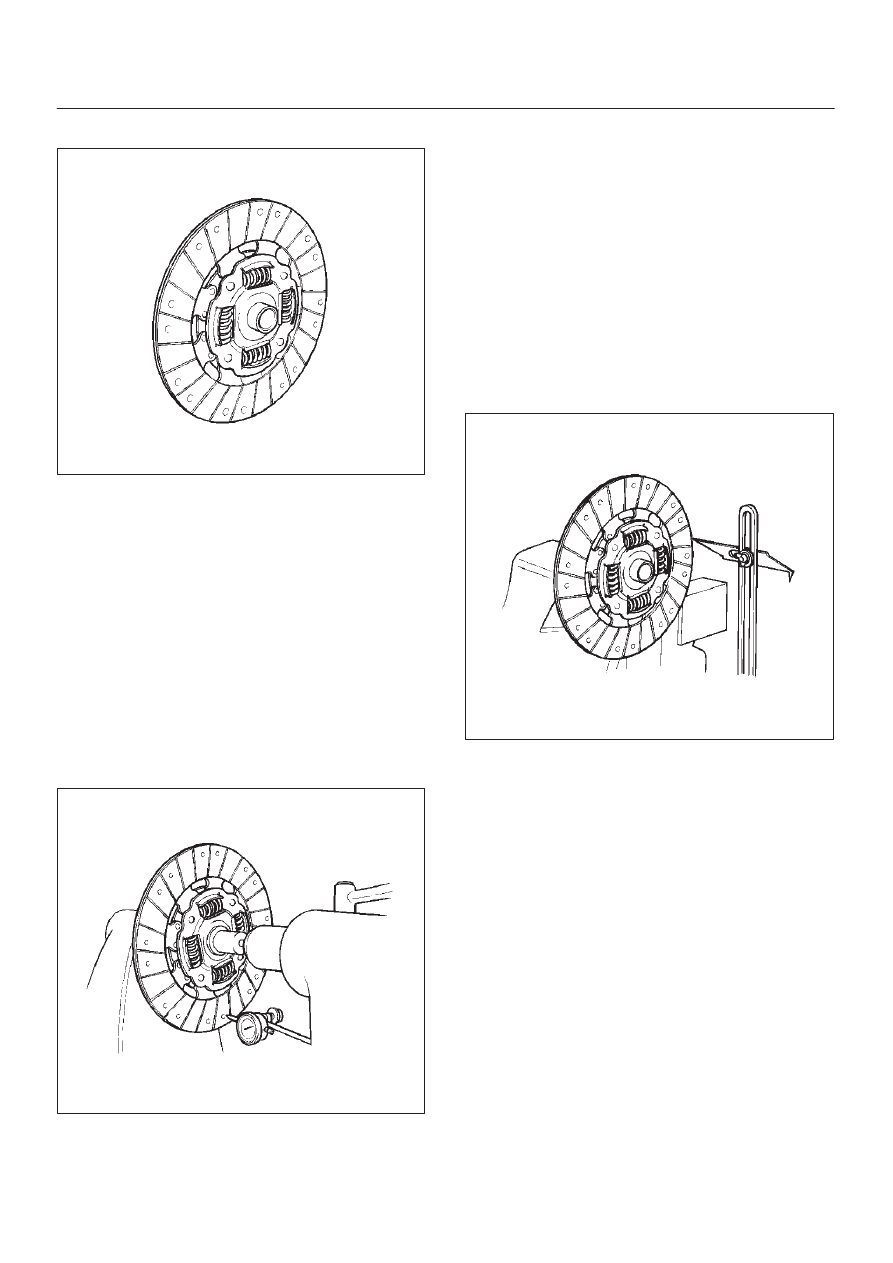

Driven Plate Assembly

201RS007

1. Visually check the torsion spring for looseness,

breakage, and weakening.

2. If any of these conditions are discovered, the driven

plate assembly must be replaced.

3. Visually check the facing surfaces for cracking and

excessive scorching.

4. Visually inspect the facing surfaces for the presence

of oil or grease.

5. If any of these conditions are discovered, the facing

must be cleaned or replaced.

6. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

7. Minor ridges on the top gear shaft spline may be

removed with an oil stone.

Driven Plate Warpage

201RS008

1. Insert the clutch pilot aligner into the driven plate

splined hub.

2. The clutch pilot aligner J-24547 must be held

perfectly horizontal.

3. Set a dial indicator to the driven plate outside

circumference.

4. Slowly turn the driven plate.

5. Read the dial indicator as you turn the driven plate.

6. If the measured value exceeds the specified limit, the

driven plate assembly must be replaced.

Driven Plate Warpage

Standard: 0.7 mm (0.028 in)

Limit: 1.0 mm (0.039 in)

Driven Plate Splined Hub Spline Wear

201RS009

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear

shaft spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

5. Measure the spline rotation play as you turn the

driven plate.

6. If the measured value exceeds the specified limit, the

driven plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear

Standard: 0.5 mm (0.020 in)

Limit: 1.0 mm (0.039 in)