Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 877

6E–532

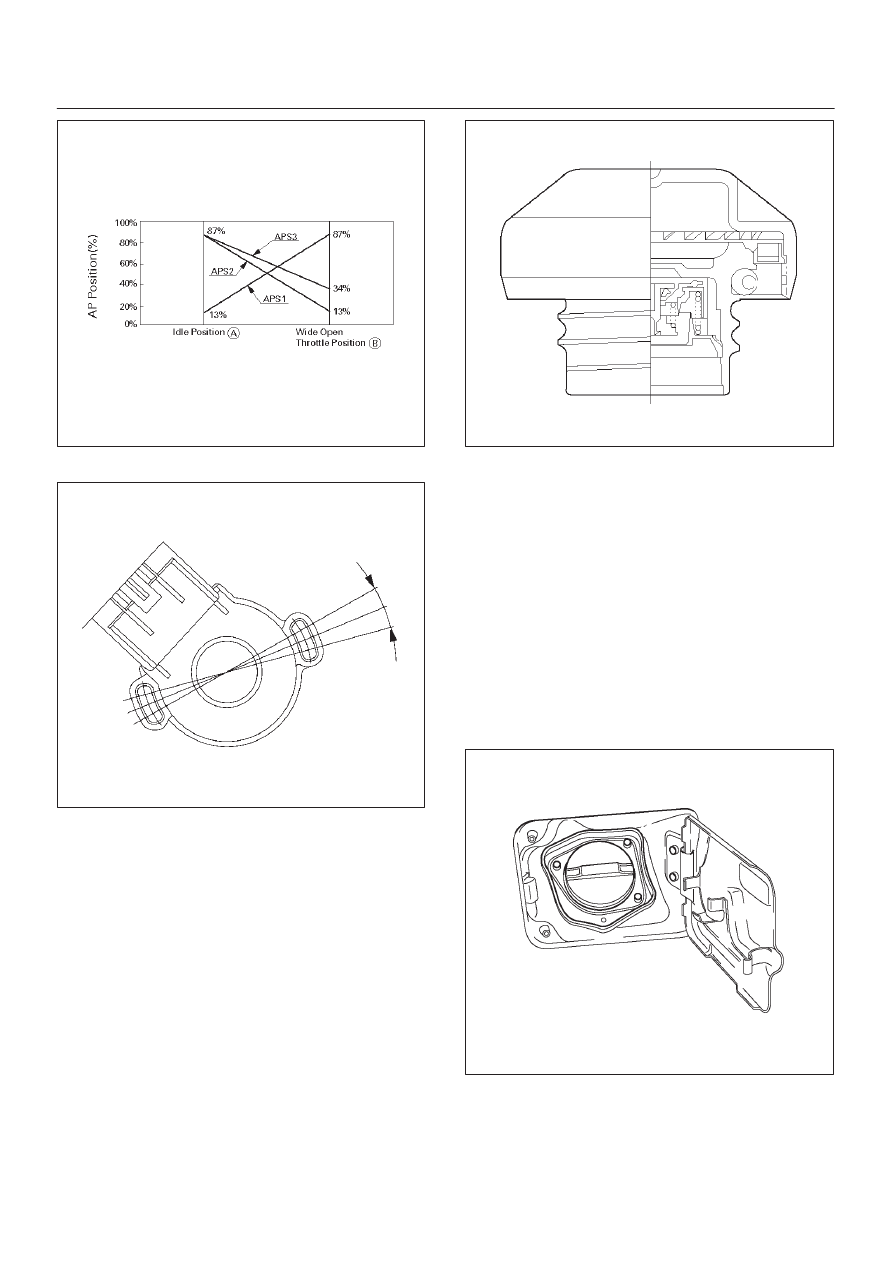

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

060RY00305

4. If the problem was found, adjust as necessary.

101RY00011

Fuel Filler Cap

General Description

The fuel filler cap includes a vacuum valve and a pressure

valve.

If high vacuum or high pressure occurs in the fuel tank,

each valve works to adjust the pressure in order to

prevent damage to the tank.

TS23767

Inspection Procedure

NOTE: Replace the fuel filler cap with the same type of

filler cap that was originally installed on the vehicle.

D

Check the seal ring in the filler cap for any abnormality

and for seal condition.

D

Replace the filler cap if any abnormality is found.

Fuel Filter

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the fuel filler cap.

060R200219