Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 878

6E–536

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

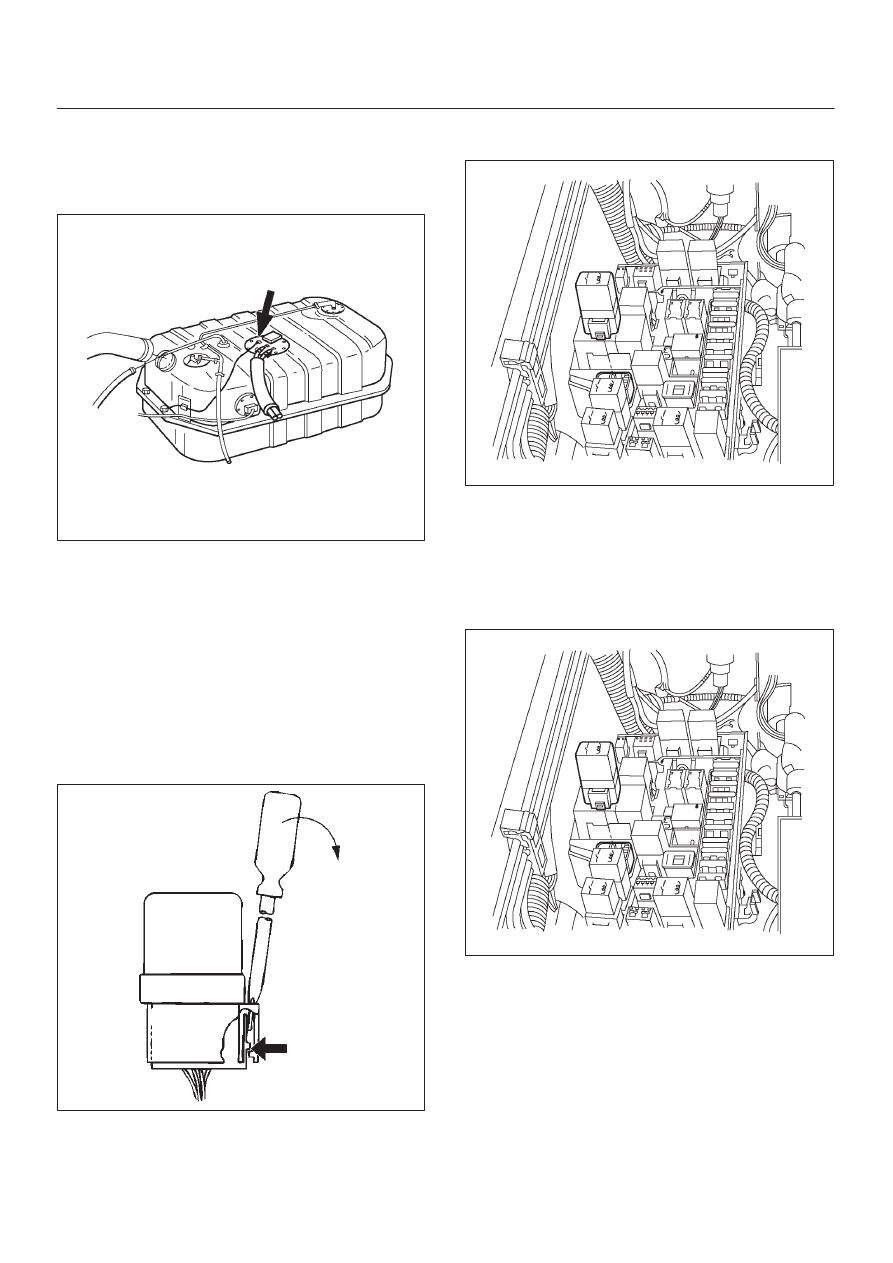

Fuel Pump Assembly

Removal Procedure

Refer to

Fuel Tank section.

060R200225

Fuel Pump Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Insert a small screwdriver into the catch slot on the

forward side of the fuel pump relay.

D

The screwdriver blade will release the catch inside.

D08RY00291

4. Pull the relay straight up and out of the fuse and relay

box.

060R200195

Installation Procedure

1. Insert the relay into the correct place in the fuse and

relay box with the catch slot facing forward.

2. Press down until the catch engages.

D

An audible “click” will be heard.

060R200195

3. Install the fuse and relay box cover.