Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 721

6A–65

ENGINE MECHANICAL

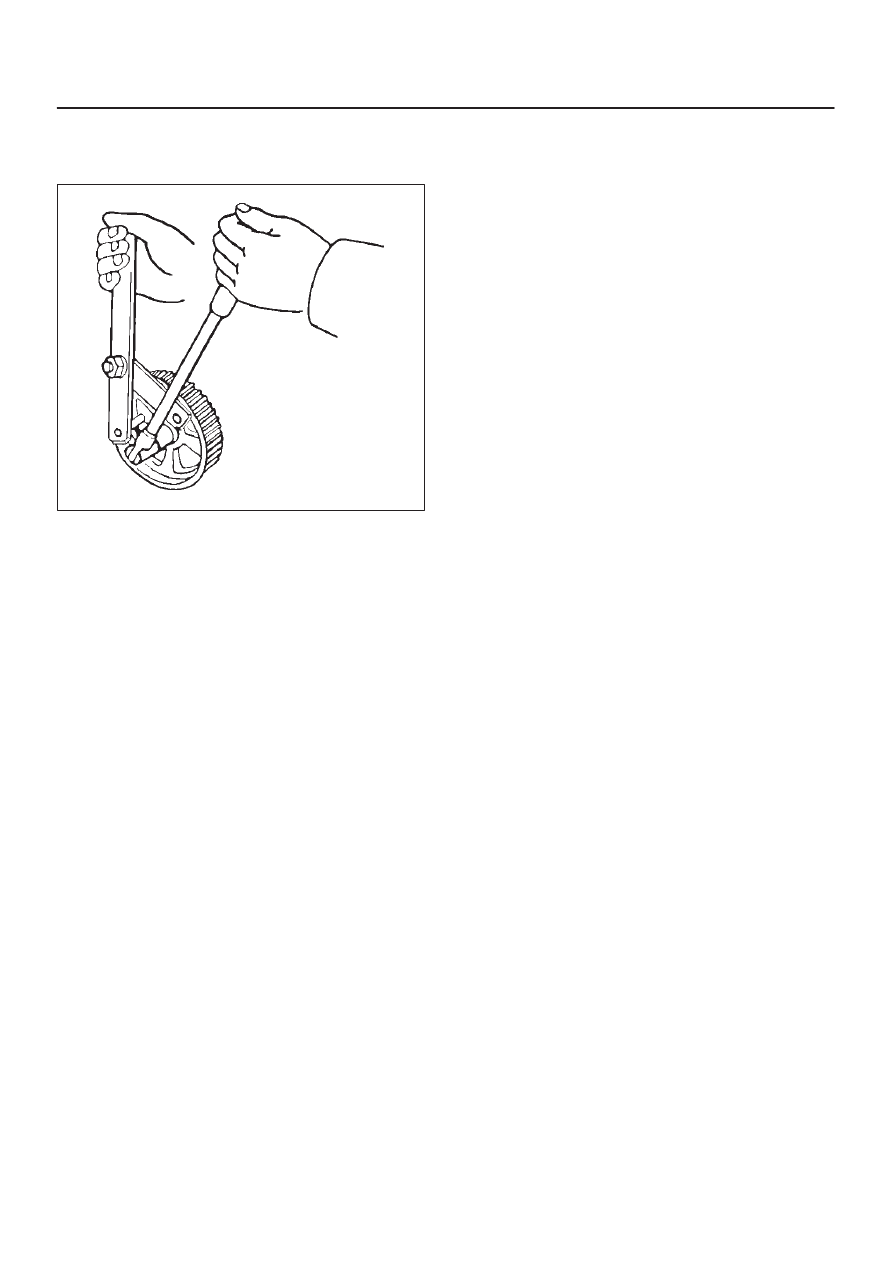

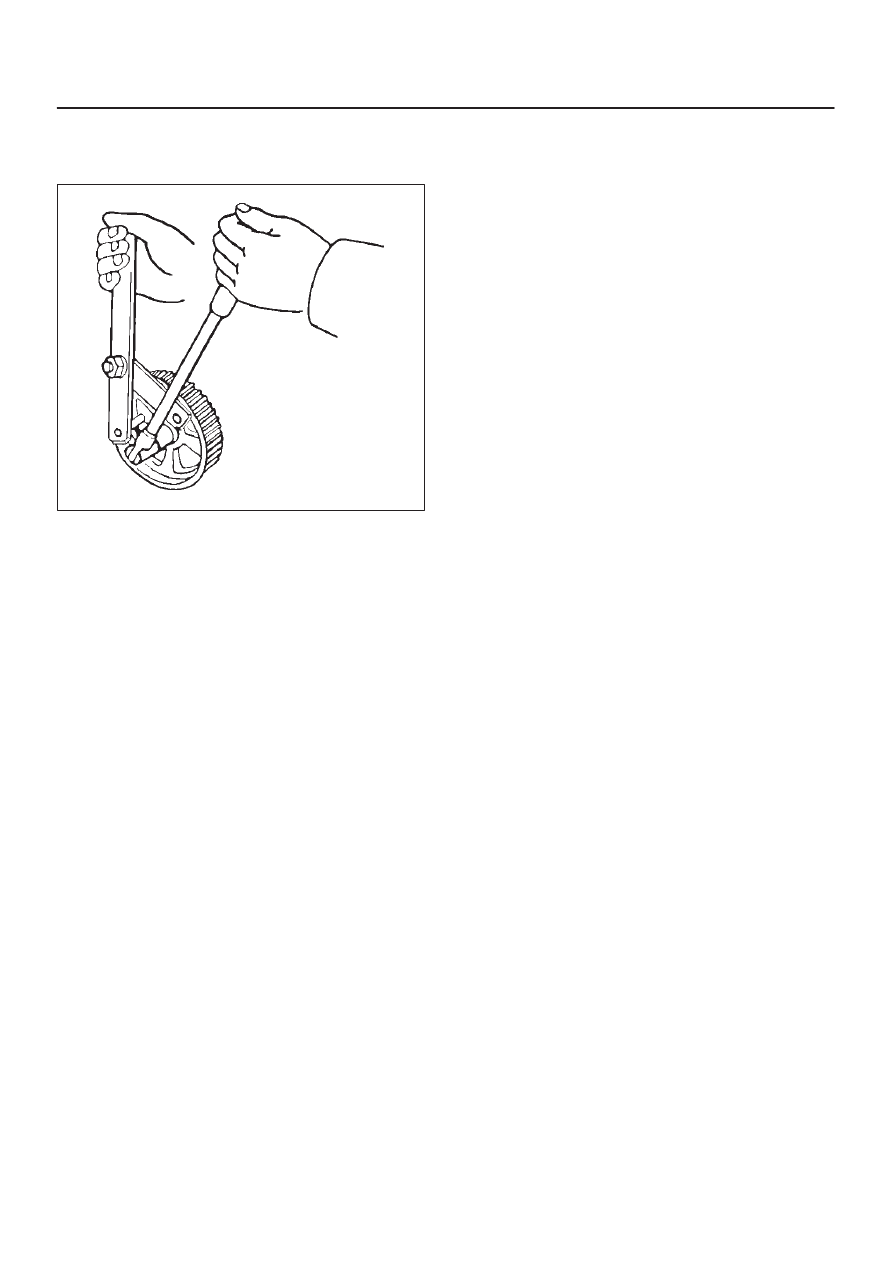

5. Tighten bolt for camshaft drive gear pulley to the

specified torque using the J–43041 universal holder.

Torque: 98 N·m (72 lb ft)

014RW060

Index Isuzu Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross - service repair manual 1999-2002 year

|

|

|

6A–65 ENGINE MECHANICAL 5. Tighten bolt for camshaft drive gear pulley to the specified torque using the J–43041 universal holder. Torque: 98 N·m (72 lb ft) 014RW060 |