Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 410

7A–53

AUTOMATIC TRANSMISSION (4L30–E)

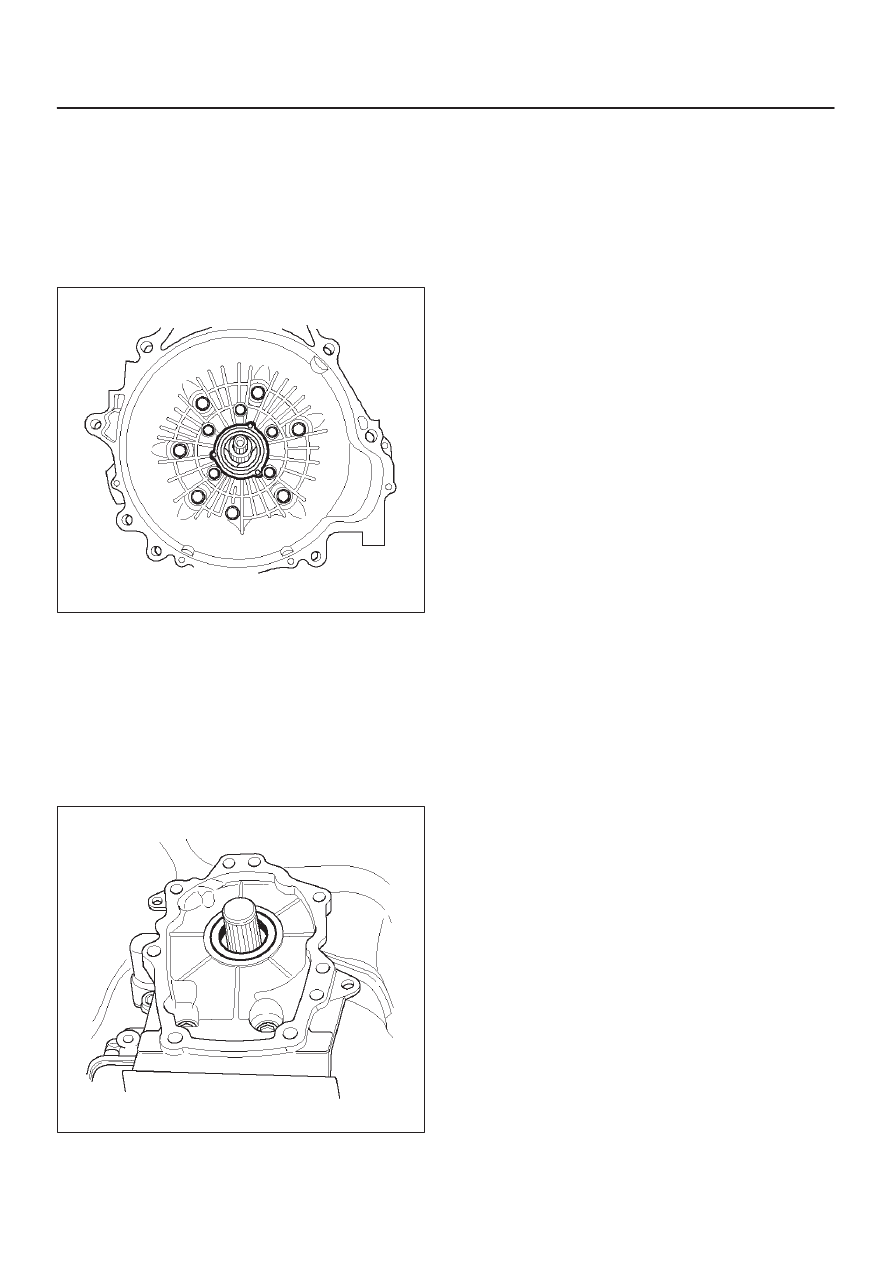

Front Oil Seal (Converter Housing)

Removal

1. Remove transmission assembly from the vehicle.

Refer to

Transmission Assembly in this section.

2. Remove torque converter from converter housing.

3. Remove three screws and oil seal ring from converter

housing.

241RW008

Installation

1. Apply clean ATF to the new oil seal ring lip.

D

Install oil seal ring to converter housing. Tighten the

screws to the specified torque.

Torque: 3 N

•

m (26 lb in)

2. Install torque converter to converter housing.

3. Install transmission assembly to the vehicle. Refer to

Transmission Assembly in this section.

Rear Oil Seal (Extension Assembly)

Removal

1. Remove transfer case assembly (4

×

4) or extension

assembly (4

×

2) from the vehicle. Refer to

Transfer

Case in Drive Line/Axle section (4

×

4).

2. Remove rear oil seal from transmission extension

assembly.

241RW005

Installation

1. Use J–36797 extension assembly oil seal installer,

and install the rear oil seal to the transmission

extension assembly.

2. Install the transfer case assembly (4

×

4) or extension

assembly (4

×

2) to the vehicle. Refer to

Transfer Case

in Drive Line/Axle section (4

×

4).