Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 408

7A–45

AUTOMATIC TRANSMISSION (4L30–E)

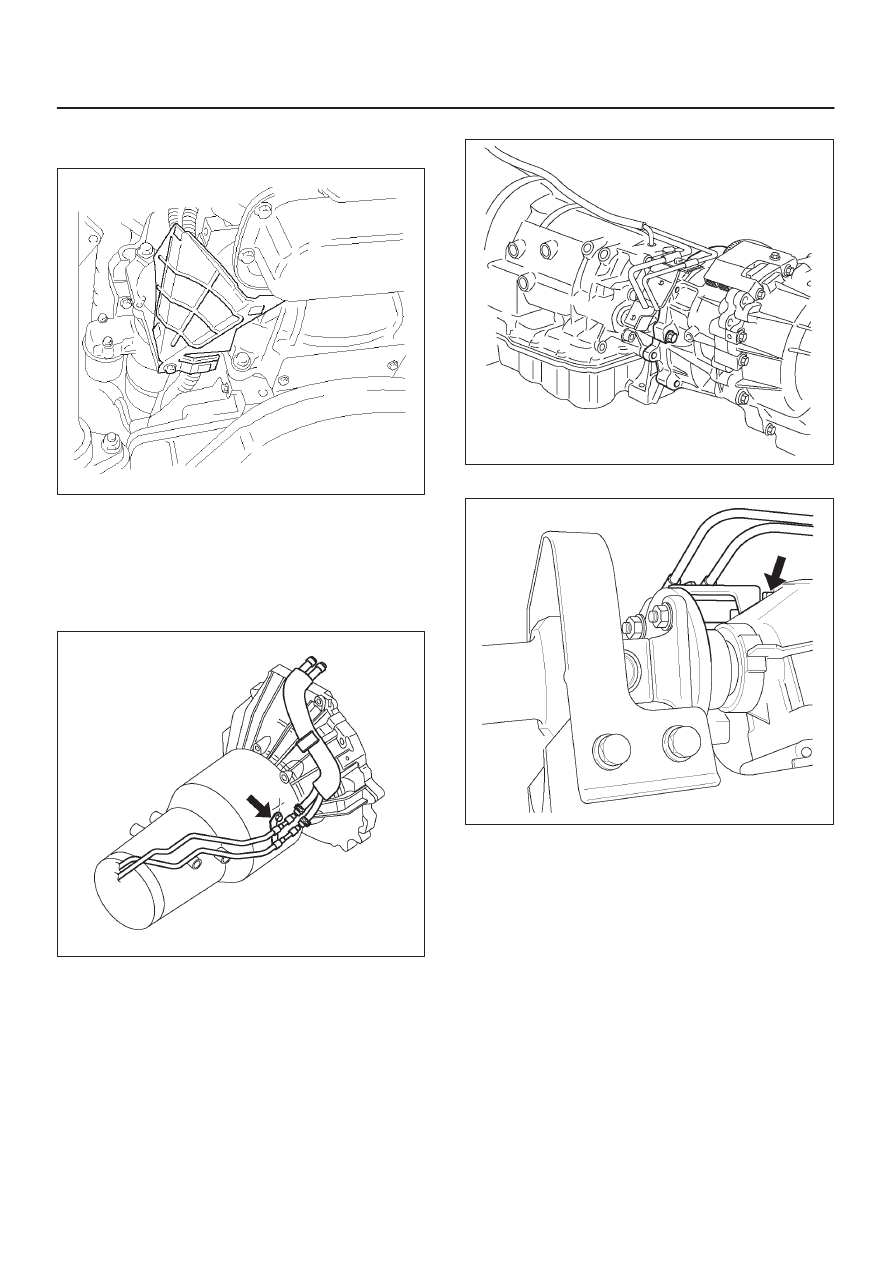

12. Install harness heat protector.

Torque: 6 N

•

m (52 lb in)

815RW002

13. Connect transmission harness connector and clip.

Connector : Adapter case, mode switch, main case,

magnetic sensor, transfer connectors (4

×

4) and car

speed sensor.

14. Connect fuel pipe bracket to transmission side.

NOTE: See “NOTE” of removal steps.

141R200003

(4

×

4)

240R200010

(4

×

2)

141R200002