Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 215

6A–47

ENGINE MECHANICAL (6VE1 3.5L)

Installation

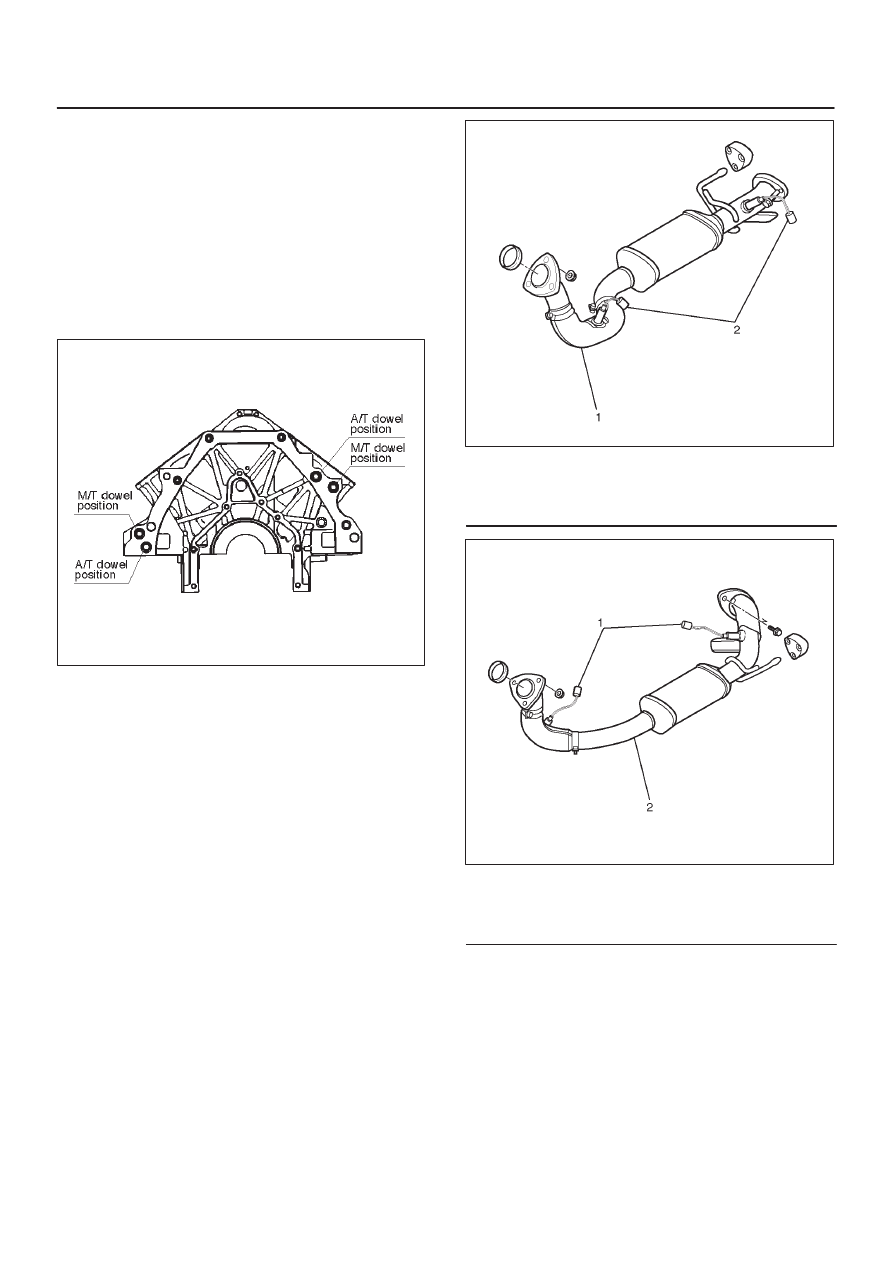

CAUTION: When assembling the engine and

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side.

NOTE: Take care that dowel positions are different

between the manual transmission and the automatic

transmission.

If the engine is assembled in the condition that the dowels

have not been mounted in the specified positions, the

transmission may be damaged.

012RS009

1. Install engine assembly. Tighten engine mount fixing

bolts to frame to the specified torque.

Torque: 41 N·m (30 lb ft)

2. Reconnect fuel hose to fuel pipe on engine.

3. Install transmission assembly. Refer to Transmission

section in this manual.

4. Reconnect two heater hoses to engine.

5. Install flywheel dust covers.

6. Install exhaust pipe and temporally tighten two (each

bank) rear exhaust flange nuts then tighten three stud

nuts (each bank) between exhaust manifold and

exhaust pipe, finally tighten rear side nuts to the

specified torque.

Torque:

Nuts: 43 N·m (32 lb ft)

Stud nuts: 67 N·m (49 lb ft)

150R200002

Legend

(1) Exhaust Front Pipe RH

(2) O

2

Sensor

150R200003

Legend

(1) O

2

Sensor

(2) Exhaust Front Pipe LH

7. Reconnect O

2

sensor connector.

8. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 N·m (16 lb ft) for fan pulley and fan

bracket.

Torque : 7.5 N·m (66.4 lb in) for fan and clutch

assembly.