Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 194

5C–93

POWER–ASSISTED BRAKE SYSTEM

Front Disc Brake Rotor

Inspection

In the manufacturing of the brake rotor, all the tolerances

regarding surface finish, parallelism and lateral runout are

held very closely. Maintaining these tolerances provides

the surface necessary to assure smooth brake operation.

Lateral Runout

Lateral runout is the movement of the rotor from side to

side as it rotates on the spindle. This could also be

referred to as “rotor wobble”.

This movement causes the piston to be knocked back into

its bore. This results in additional pedal travel and a

vibration during braking.

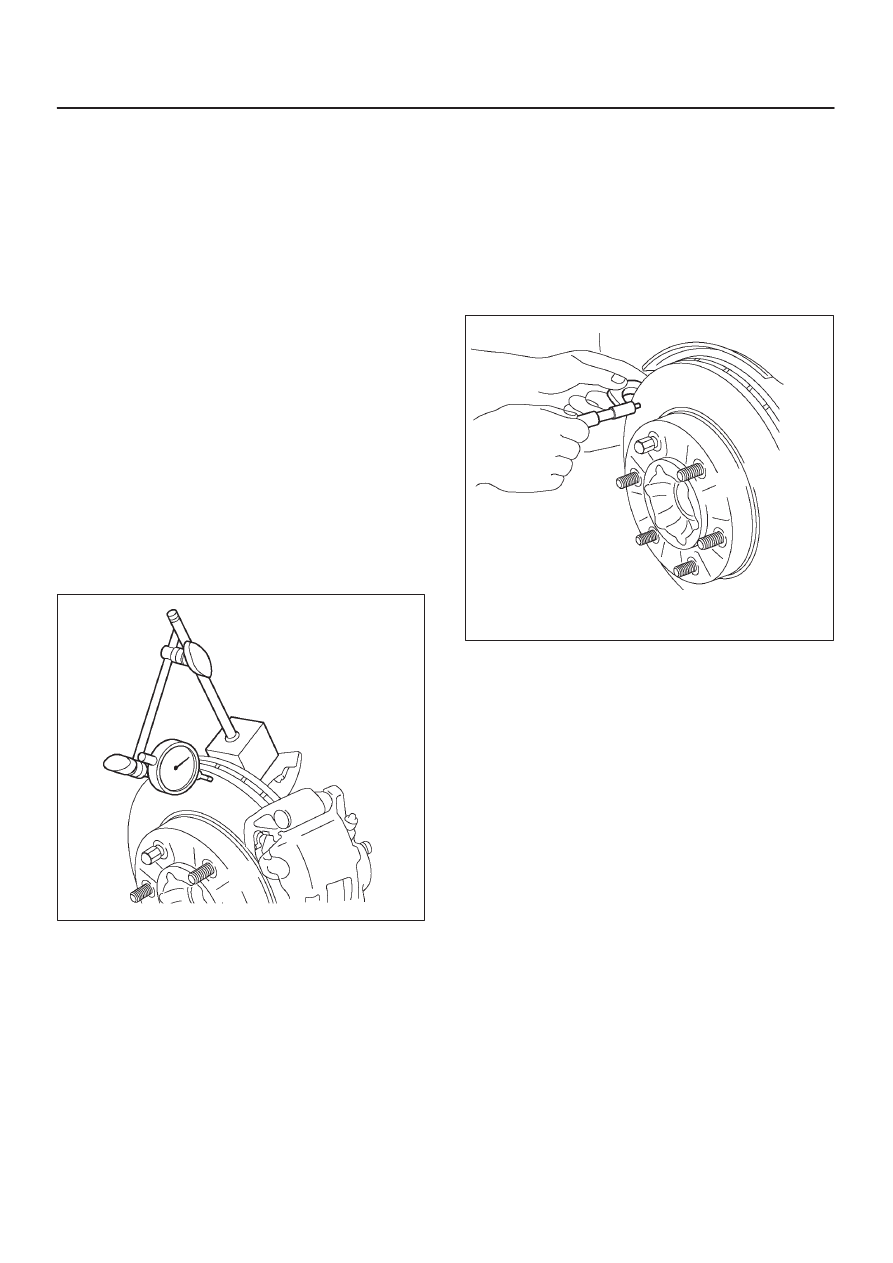

Checking Lateral Runout

1. Adjust the wheel bearing correctly, refer to

Differential

in Section 4A.

2. Attach the dial indicator accordingly so that the stem

contacts the rotor surface to approximately 29mm

(1.14 in) from the rotor edge.

3. Rotate the rotor one complete turn and inspect for

signs of lateral runout. Lateral runout should not

exceed 0.13 mm (0.005 in).

Maximum runout: 0.13 mm (0.005 in)

411R200008

Parallelism

Parallelism is the measurement of thickness of the rotor

at four or more points around the circumference of the

rotor. All measurement must be made at 29 mm (1.14 in)

from the edge of the rotor.

The rotor thickness must not vary more than 0.010 mm

(0.0004 in) from point to point.

Maximum runout: 0.010 mm (0.0004 in)

411R200007

Replacing Brake Rotors

When installing new brake rotors, do not refinish the

surfaces. These parts are at the correct level of surface

finish.

Refinishing Brake Rotors

Accurate control of the rotor tolerances is necessary for

proper performance of the disc brakes. Machining of the

rotor should be done only with precision equipment. All

brake rotors have a minimum thickness dimension cast

into them. This dimension is the minimum wear

dimension and not a refinish dimension. The minimum

wear dimension is 24.60 mm (0.969 in). The minimum

refinish dimension is 26.00 mm (1.024 in).

When refinishing rotors, always use sharp cutting tools or

bits. Dull or worn tools leave a poor surface finish which

will affect initial braking performance. Vibration

dampening attachments should always be used when

refinishing braking surfaces. These attachments

eliminate tool chatter and will result in better surface

finish.

After refinishing, replace any rotor that does not meet the

minimum thickness of 26.00 mm (1.024 in). Do not use a

brake rotor that exceeds the manufacturers

specifications.