Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 195

5C–97

POWER–ASSISTED BRAKE SYSTEM

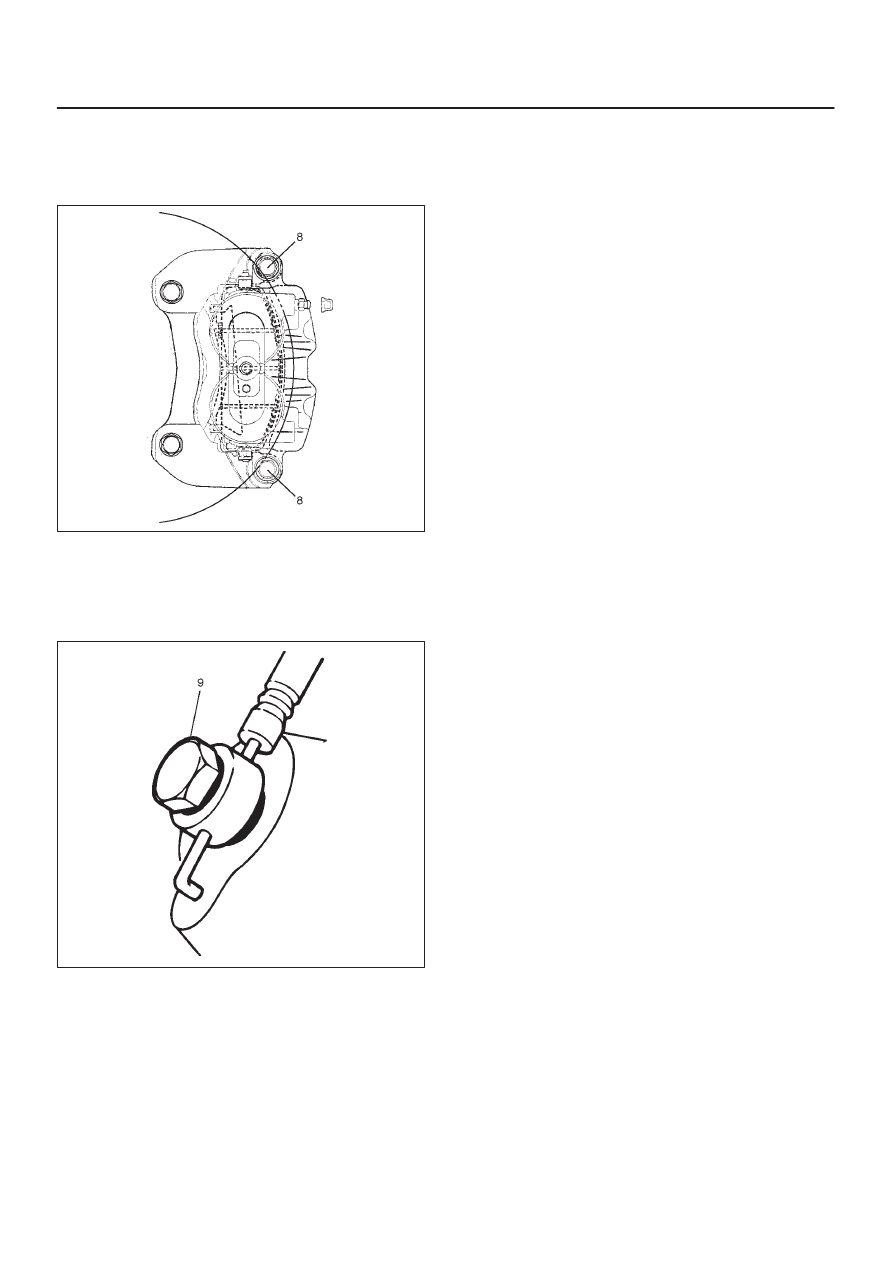

4. Install caliper assembly.

5. Install pin bolt (8) and tighten the bolt to the specified

torque.

Torque: 45 N·m (33 lb ft)

302R200010

6. Install brake flexible hose, always use new gaskets

and be sure to put the hooked edge of the flexible

hose end into the anti–rotation cavity then tighten the

I–bolt (9) to the specified torque.

Torque: 35 N·m (26 lb ft)

302R200021

7. Install wheel and tire assembly, referring to

Wheels

and Tires System in Section 3E.

8. Bleed brakes. Refer to

Hydraulic Brakes in this

section.