Content .. 1737 1738 1739 1740 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1739

4C–14

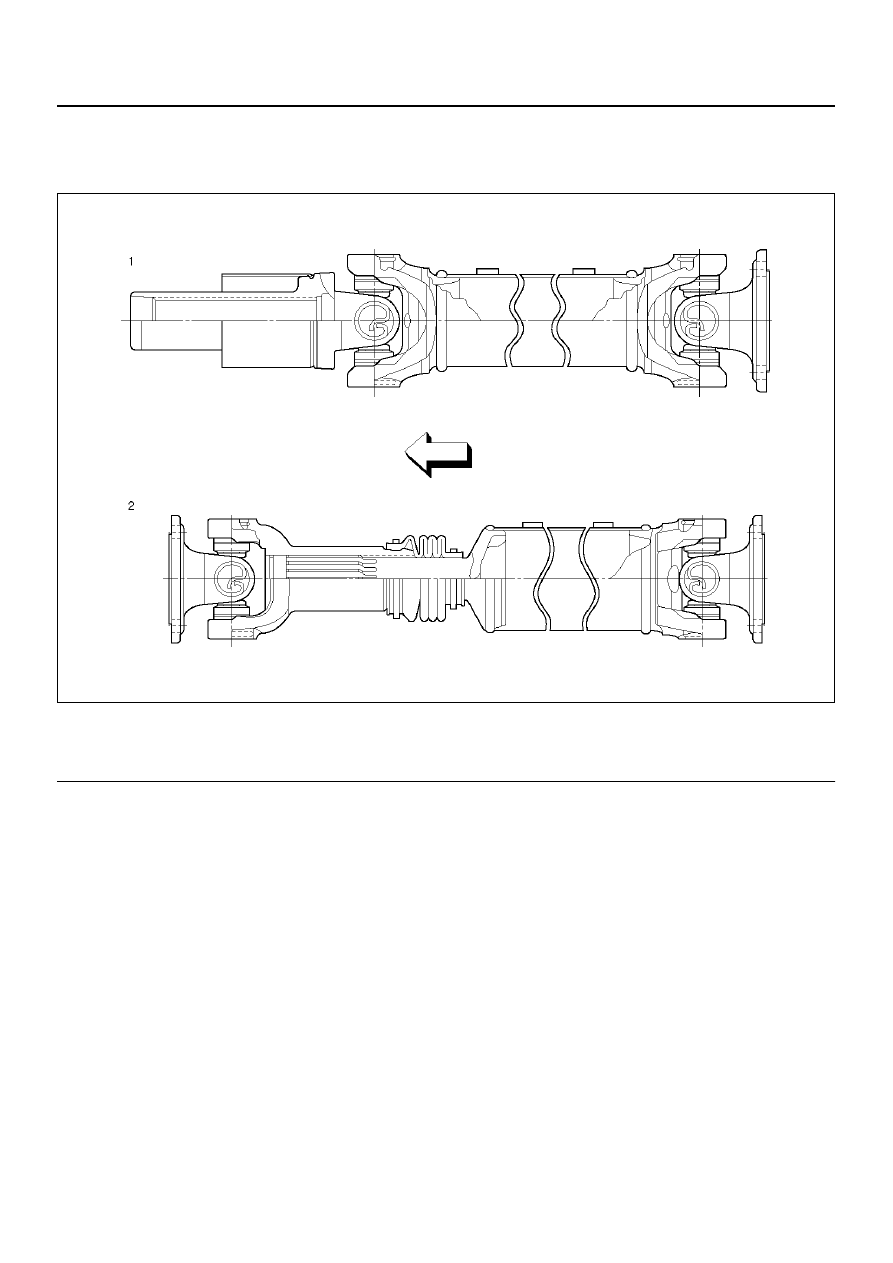

DRIVE SHAFT SYSTEM

Rear Propeller Shaft

General Description

401RX00005

EndOFCallout

Propeller Shaft

Torque is transmitted from the transmission to the rear

axle through one propeller shaft and universal joint

assemblies. All propeller shafts are the balanced tubular

type. A splined slip joint is provided in some drivelines.

• Since the propeller shaft is balanced carefully,

welding or any other modification are not permitted.

• Alignment marks should be applied to each propeller

shaft before removal.

• Be sure vehicle is stopped, engine is not running,

brake is secured and vehicle is secured to prevent

injury.

• Be careful not to grip the propeller shaft tube too

tightly in the vise as this will be cause deformation.

Phasing

The propeller shaft is designed and built with the yoke

lugs (ears) in line with each other. This design produces

the smoothest running shaft possible, called phasing.

Vibration can be caused by an out-of-phase propeller

shaft. The propeller shaft will absorb vibrations from

speeding up and slowing down each time the universal

joint spins. This vibration would be the same as a

person snapping a rope and watching the "wave"

reaction flow to the end. A propeller shaft working in

phase would be similar to two persons snapping a rope

at the same time, and watching the "waves" meet and

cancel each other out. In comparison, this would be the

same as the universal joints on a propeller shaft. A total

cancellation of vibration produces a smooth flow of

power in the driveline. It is very important to apply a

reference mark to the propeller shaft before removal, to

assure installation alignment.

Legend

(1) For Y22SE 4

´2 M/T Model

(2) For 6VD1 Model and Y22SE 4

´2 A/T Model