Content .. 1738 1739 1740 1741 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1740

4C–18

DRIVE SHAFT SYSTEM

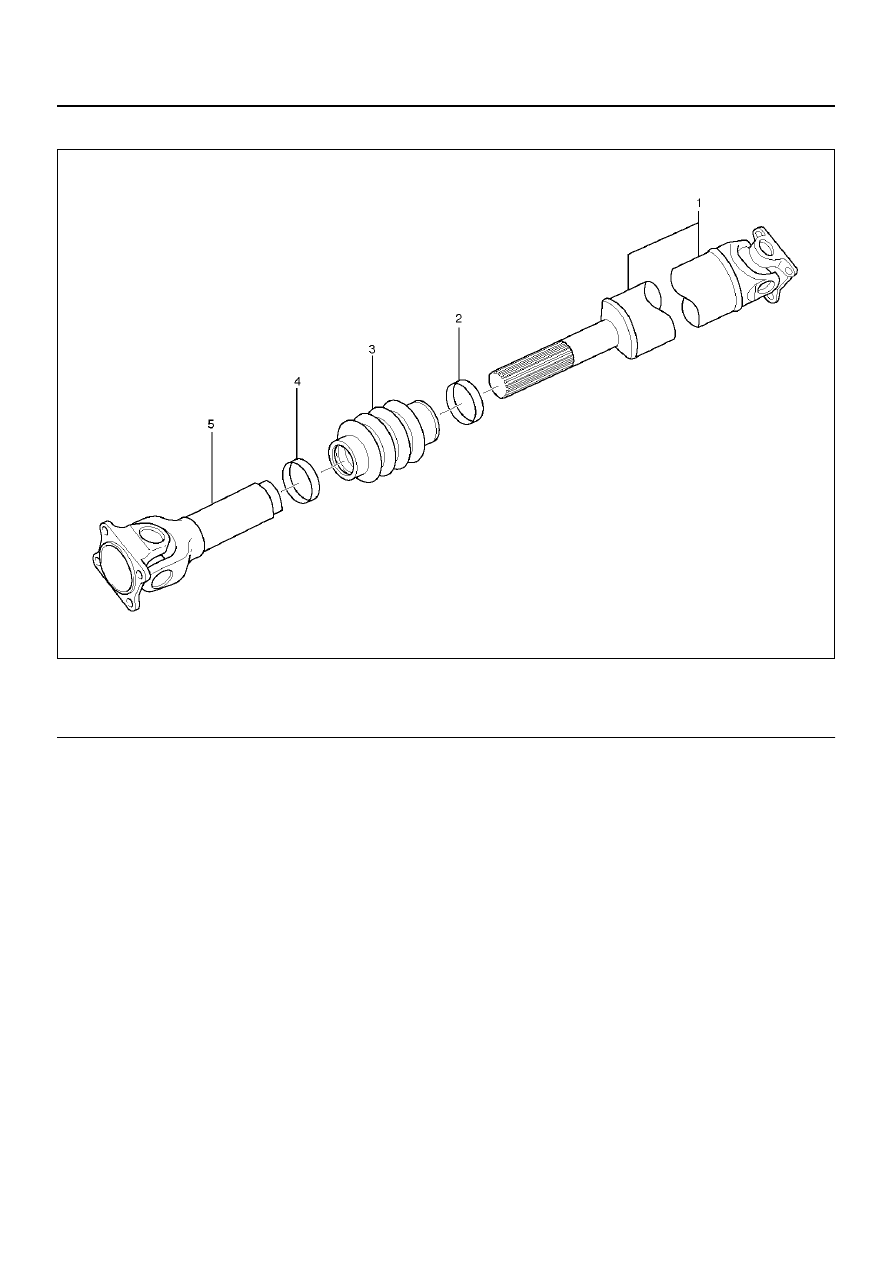

Slip Joint Disassembly (6VD1 Model Only)

401RW081

EndOFCallout

1. Lay the shaft horizontally on a bench and secure.

2. Indicate the original assembled position by marking

the phasing of the shaft prior to disassembly.

3. Using the flat blade of a screwdriver, pry the loose

end of the boot clamp upwards and away from the

propeller shaft boot. Be careful not to damage the

boot.

4. When boot clamps becomes loose, remove by

hand.

5. Repeat for the other boot clamp.

6. Remove the spline yoke assembly from the tube

assembly, by securing the boot with one hand and

pulling on the spline yoke.

7. Remove the boot from the tube assembly.

Legend

(1) Spline Yoke and Universal Joint Assembly

(2) Clamp

(3) Boot

(4) Clamp

(5) Tube and Universal Joint Assembly