Content .. 1735 1736 1737 1738 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1737

4C–6

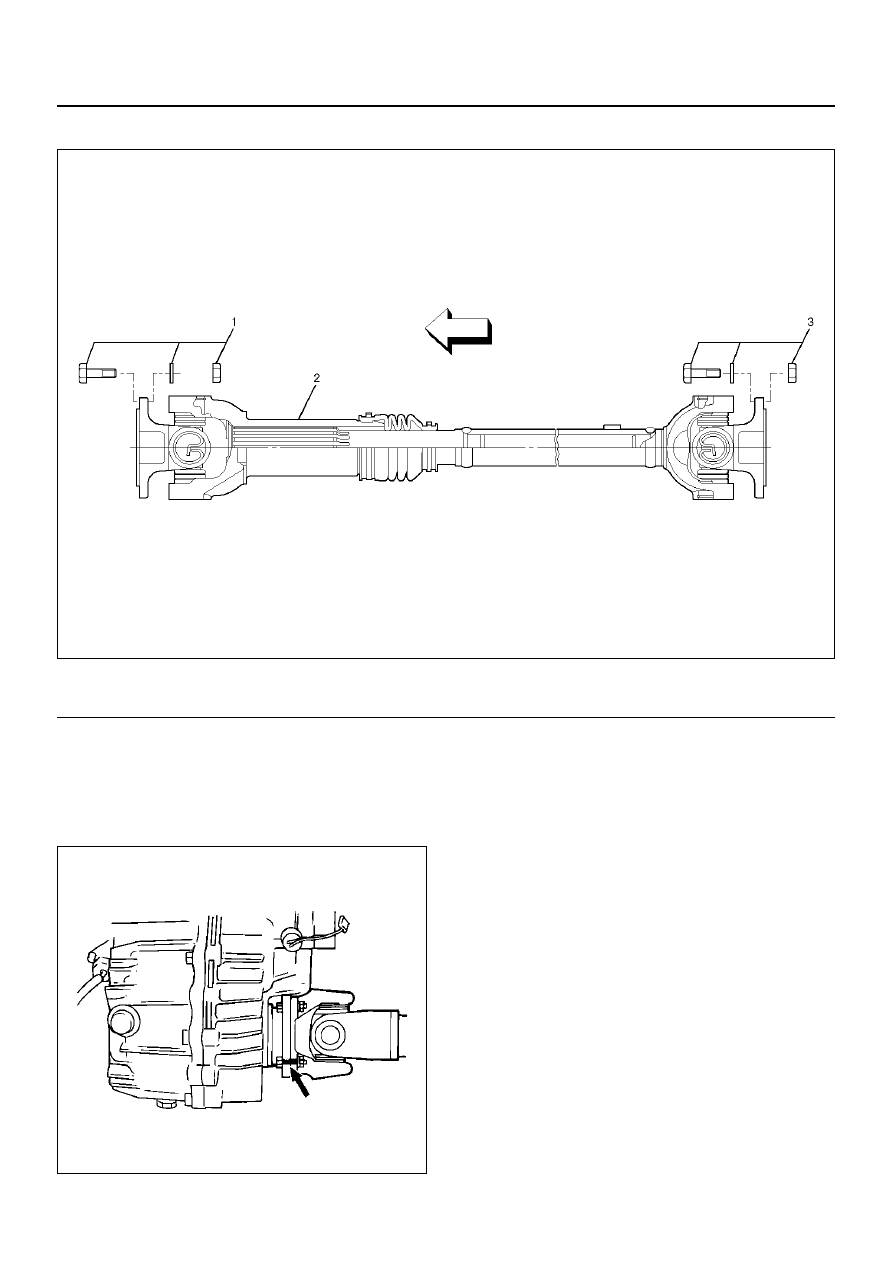

DRIVE SHAFT SYSTEM

Front Propeller Shaft and Associated Parts

401RW093

EndOFCallout

Removal

1. Raise the vehicle on a hoist.

NOTE: Apply alignment marks on the flange at the front

propeller shaft both front and rear side.

401RS020

2. Remove bolt, nut and washer (Front axle side).

3. Remove bolt, nut and washer (Transfer side).

4. Remove front propeller shaft.

Installation

NOTE: Never install the shaft assembly backwards.

Never insert bar between yoke lugs when tightening or

removing bolts. Completely remove the black paint from

the connecting surface of flange coupling on each end

of propeller shaft. Clean so that no foreign matter will be

caught in between.

1. Align the mark which is applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque:63 N·m (46lb ft)

Legend

(1) Bolt, Nut and Washer (Front Axle Side)

(2) Front Propeller Shaft (Single Cardan Type)

(3) Bolt, Nut and Washer (Transfer Side)