Content .. 1706 1707 1708 1709 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1708

9J1–43

RESTRAINT CONTROL SYSTEM

DTC 25 Driver Deployment Loop Short To Ignition

CAUTION: When Diagnostic Trouble Code (DTC) 25

has been set, it is necessary to replace the Sensing

and Diagnostic Module (SDM). Setting DTC 25 will

also cause DTC 71 to set. When a scan tool “CLEAR

CODES” command is issued and the malfunction is

no longer present, DTC 71 will remain current.

Ensure that the short to voltage condition is repaired

prior to installing a replacement SDM to avoid

damaging the SDM.

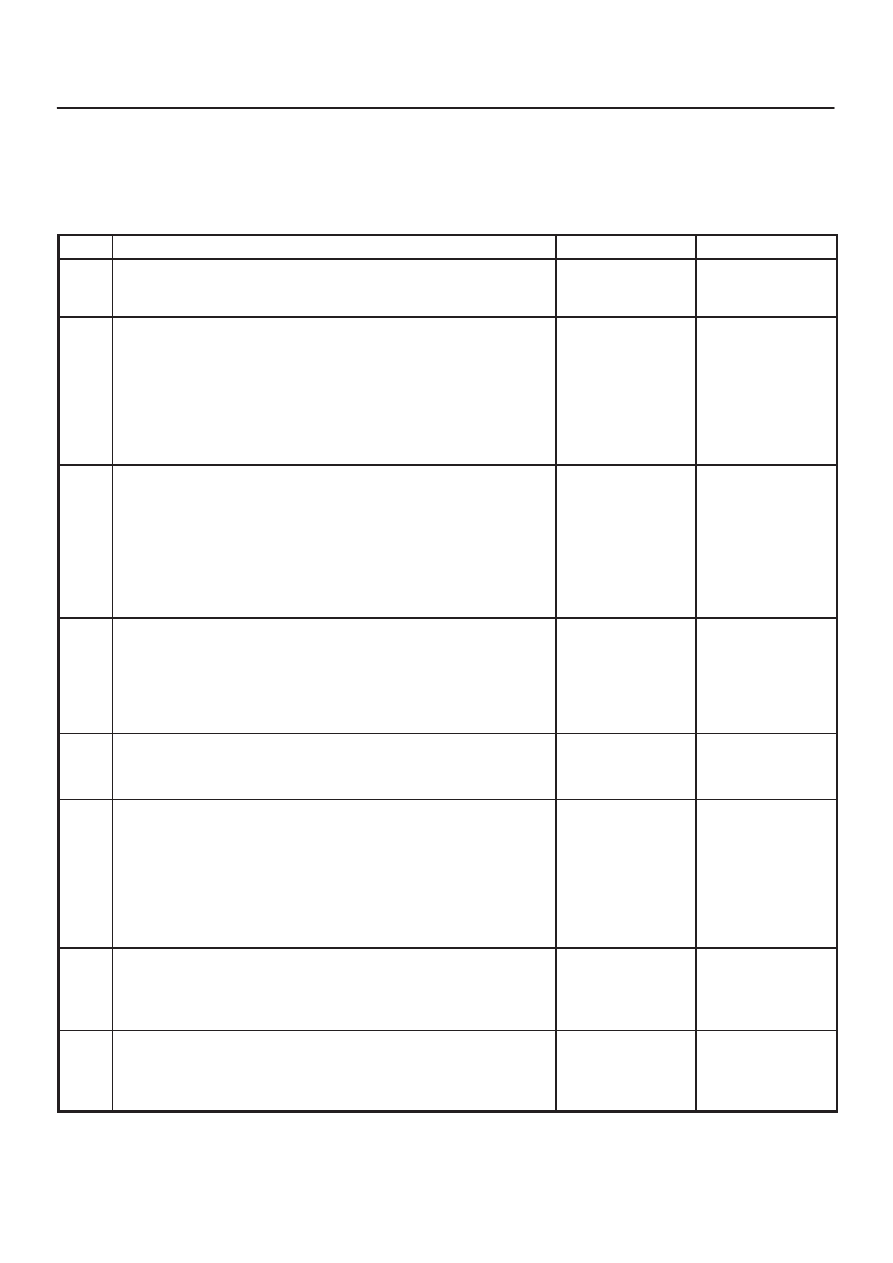

Step

Action

Yes

No

1

Was the “SRS Diagnostic System Check” performed?

Go to

Step 2

Go to

“SRS

Diagnostic

System Check.”

2

1. When measurements are requested in this chart use J–39200

DVM with correct terminal adapter from J–35616–A.

2. Ignition switch “OFF.”

3. Connect scan tool data link connector. Follow directions given

in the scan tool operator’s manual.

4. Ignition switch “ON.”

5. Read driver sense low.

Is driver sense low more than 3.5 volts?

Go to

Step 3

Go to

Chart A

3

1. Ignition switch “OFF.”

2. Disconnect SRS coil assembly yellow 2–pin connector at the

base of the steering column. Leave passenger air bag

assembly connected.

Connect SRS driver / passenger load tool J–41433 and

appropriate adapter to SRS coil assembly harness connector.

3. Ignition switch “ON.”

Is driver sense low more than 3.5 volts?

Go to

Step 4

Go to

Step 6

4

1. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS drive / passenger load tool.

4. Measure resistance on SDM harness connector from terminal

“3” to terminal “12” (Ignition 1).

Does DVM display “0L” (infinite)?

Go to

Step 5

Replace SRS

harness.

Go to

Step 7

5

Measure resistance on SDM harness connector from terminal “4”

to terminal “12” (Ignition 1).

Does DVM display “0L” (infinite)?

Go to

Chart A

Replace SRS

harness.

Go to

Step 7

6

1. Ignition switch “OFF.”

2. Connect SRS driver / passenger load tool J–41433 and

appropriate adapter J–35616–A to driver air bag assembly

harness connector located of top of the steering column.

3. Reconnect SRS coil assembly harness connector at the base

of the steering column.

4. Ignition switch “ON.”

Is driver sense low more than 3.5 volts?

Ignition switch

“OFF.”

Replace SRS coil

assembly.

Go to

Step 7

Ignition switch

“OFF.”

Replace driver air

bag assembly.

Go to

Step 7

7

1. Reconnect all components, ensure all components are

properly mounted.

2. Ignition switch “ON.”

Is passenger sense low less than 3.5 volts?

Replace SDM.

Go to

Step 8

Go to

Chart A

8

1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Repeat the “SRS

Diagnostic

System Check.”

Go to

Step 8