Content .. 1162 1163 1164 1165 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1164

TRANSFER CASE

4D–25

9. Remove needle bearing (8).

10. Remove bearing collar (9).

226RS071

11. Remove ball (10).

12. Remove plate (11).

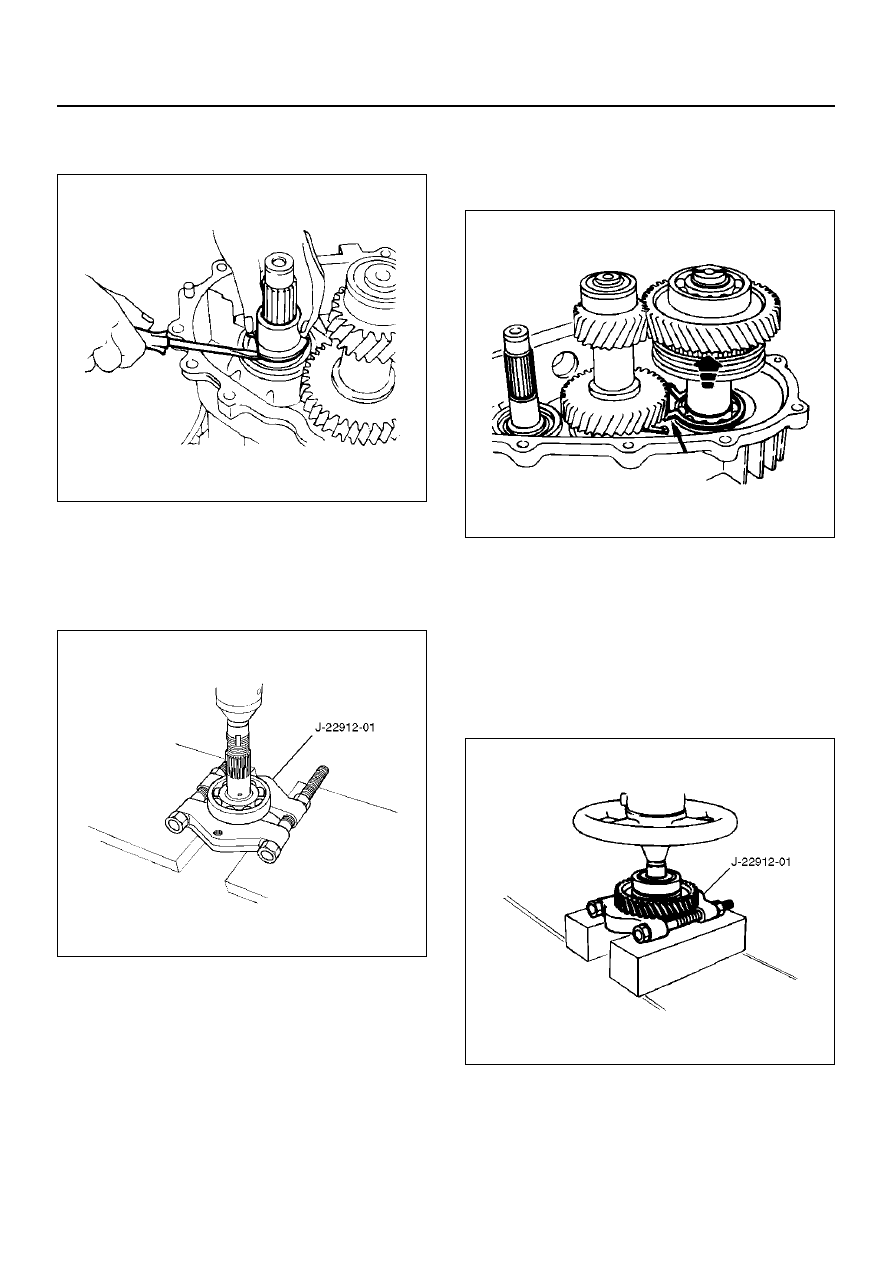

13. Use a bench press and the ball bearing remover J–

22912–01 to remove the ball bearing (12) from the

input shaft (13). (A/T)

265RS002

14. Use a pair of snap ring pliers to remove the bearing

snap ring (14).

15. Use a plastic hammer to tap the front output gear

assembly (15) free.

262RS009

16. Remove bearing snap ring (16).

17. Use a bench press and the bearing remover J–

22912–01 to remove the following parts.

18. Remove ball bearing (17), and bearing collar (18).

Remove sub–gear snap ring (19), spacer (20),

belleville spring (21), and sub–gear (anti–lash plate)

(22). (M/T)

Remove front output gear (23) and needle bearing

(24).

262RS010

19. Remove inside ring (25).

20. Remove outside ring (26).

21. Remove block ring (27).