Content .. 1128 1129 1130 1131 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1130

4A1–14

DIFFERENTIAL (FRONT)

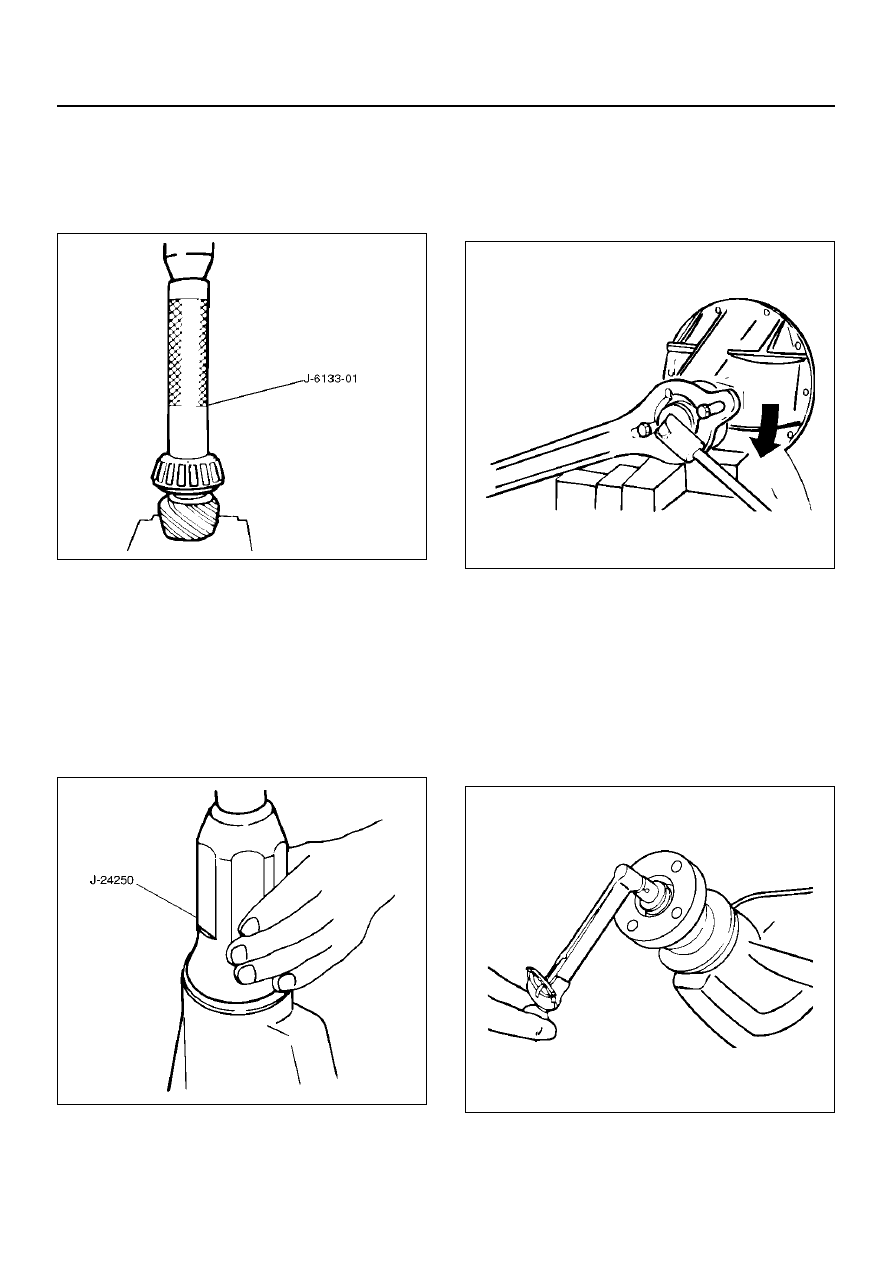

4. Place the shim on the drive pinion. Install the inner

bearing onto the pinion using an installer J–6133–01

and a press.

NOTE: Do not apply pressure to the roller cage and

apply pressure only to the inner race.

425RW036

5. Discard the used collapsible spacer and install a

new one.

6. Install pinion gear.

7. Install outer bearing.

8. Install oil seal slinger.

9. Use oil seal installer J–24250 to install a new oil

seal that has been soaked in front axle lubricant.

NOTE: Take care to use a front differential oil seal,

NOT the rear differential oil seal.

415RS011

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.

2. Tighten the nut to the specified torque using the

pinion flange holder J–8614–01.

Torque: 217N·m (160lb ft)

NOTE: Discard used flange nut and install new one and

do not over tighten the flange nut.

415RW006

3. Adjust pinion bearing preload.

a

Measure the bearing preload by using a

torque meter. Note the scale reading

required to rotate the flange.

b

Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:0.6–1.1 N·m(5.6–10.0 lb in)

NOTE: Do not tighten the flange nut more than

678 N·m(500lb ft).

425RW018