Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 88

4A2–10

DIFFERNTIAL (REAR)

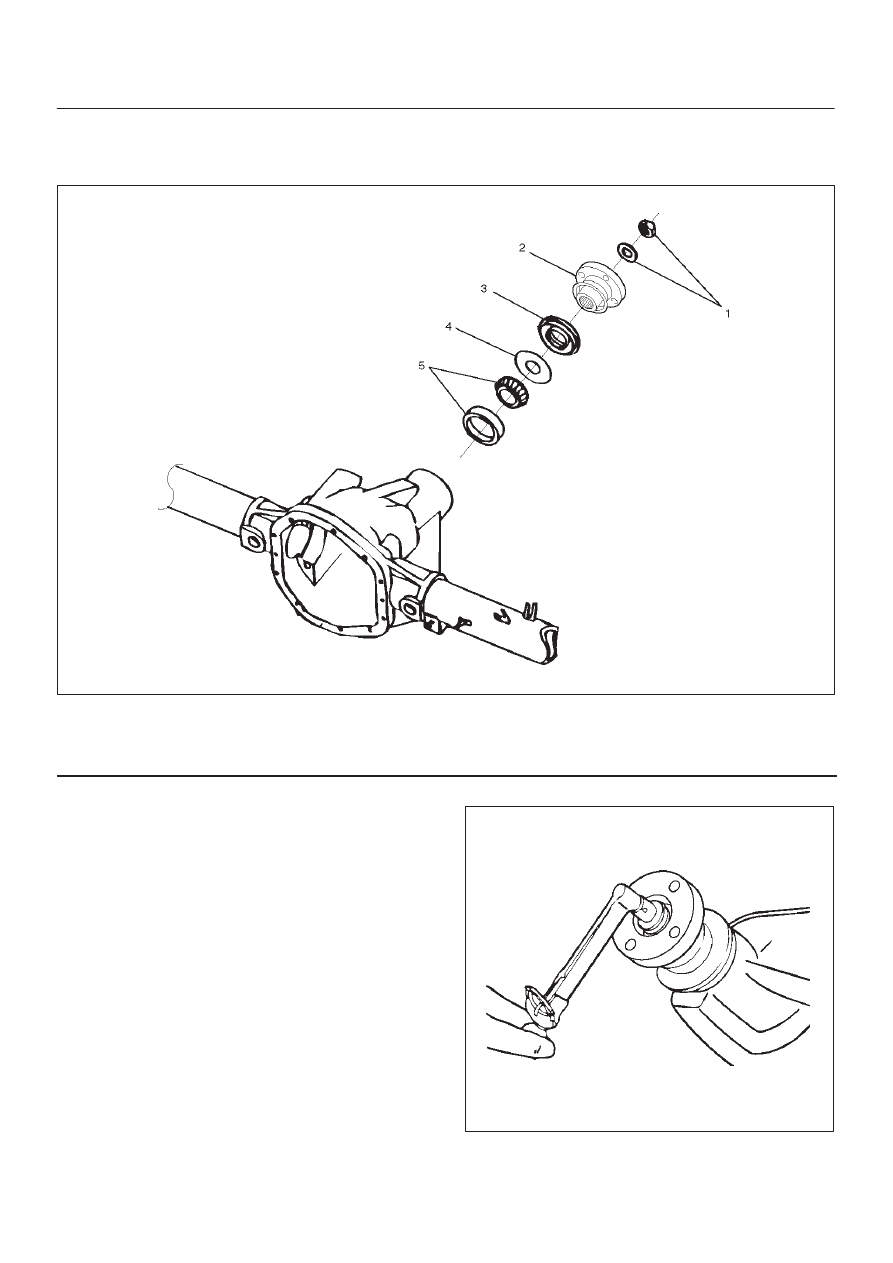

Pinion Oil Seal

Pinion Oil Seal and Associated Parts

420RW013

Legend

(1) Flange Nut and Washer

(2) Flange

(3) Oil Seal

(4) Outer Oil Seal Slinger

(5) Outer Pinion Bearing (Cup and Cone)

Removal

1. Remove the rear propeller shaft. Refer to

Rear

Propeller Shaft in this section.

2. Drain the rear axle oil.

3. Check and record preload with an inch pound torque

wrench. This will give combined pinion bearing, seal,

carrier bearing, axle bearing and seal preload.

425RW018