Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 86

4A2–2

DIFFERNTIAL (REAR)

General Description

The rear axle assembly is of the semi–floating type in

which the vehicle weight is carried on the axle housing .

The center line of the pinion gear is below the center line

of the ring gear (hypoid drive).

All parts necessary to transmit power from the propeller

shaft to the rear wheels are enclosed in a salisbury type

axle housing (a carrier casting with tubes pressed and

welded into the carrier). A removable aluminum cover at

the rear of the axle housing permits rear axle service

without removal of the entire assembly from the vehicle.

The 8.9 inch ring gear rear axle uses a conventional ring

and pinion gear set to transmit the driving force of the

engine to the rear wheels. This gear set transfers this

driving force at a 90 degree angle from the propeller shaft

to the drive shafts.

The axle shafts are supported at the wheel end of the

shaft by a roller bearing.

The pinion gear is supported by two tapered roller

bearings. The pinion depth is set by a shim pack located

between the gear end of the pinion and the roller bearing

that is pressed onto the pinion. The pinion bearing

preload is set by crushing a collapsible spacer between

the bearings in the axle housing.

The ring gear is bolted onto the differential case with 10

bolts.

The differential case is supported in the axle housing by

two tapered roller bearings. The differential and ring gear

are located in relationship to the pinion by using selective

shims and spacers between the bearing and the

differential case. To move the ring gear, shims are deleted

from one side and an equal amount are added to the other

side. These shims are also used to preload the bearings

which are pressed onto the differential case. Two bearing

caps are used to hold the differential into the rear axle

housing.

The differential is used to allow the wheels to turn at

different rates of speed while the rear axle continues to

transmit the driving force. This prevents tire scuffing

when going around corners and prevents premature wear

on internal axle parts.

The rear axle is sealed with a pinion seal, a seal at each

axle shaft end, and by a liquid gasket between the rear

cover and the axle housing.

Limited Slip Differential (LSD)

The axle assembly may be equipped with an limited slip

differential (LSD). It is similar to the standard differential

except that part of the torque from the ring gear is

transmitted through clutch packs between the side gears

and differential case.

The LSD construction permits differential action when

required for turning corners and transmits equal torque to

both wheels when driving straight ahead. However, when

one wheel tries to spin due to a patch of ice, etc., the

clutch packs automatically provide more torque to the

wheel which is not trying to spin.

In diagnosing customer complaints, it is important to

recognize two things:

1. If, both wheels slip, with unequal traction, the LSD

has done all it can possibly do.

2. In extreame cases of differences in traction, the

wheel with the least traction may spin after the LSD

has transferred as much torque as possible to the

non-slipping wheel.

Limited Slip Differntials impose additional requirements

on lubricants, and require a special lubricant or lubricant

additive. Use 80W90 GL–5 LSD lubricant.

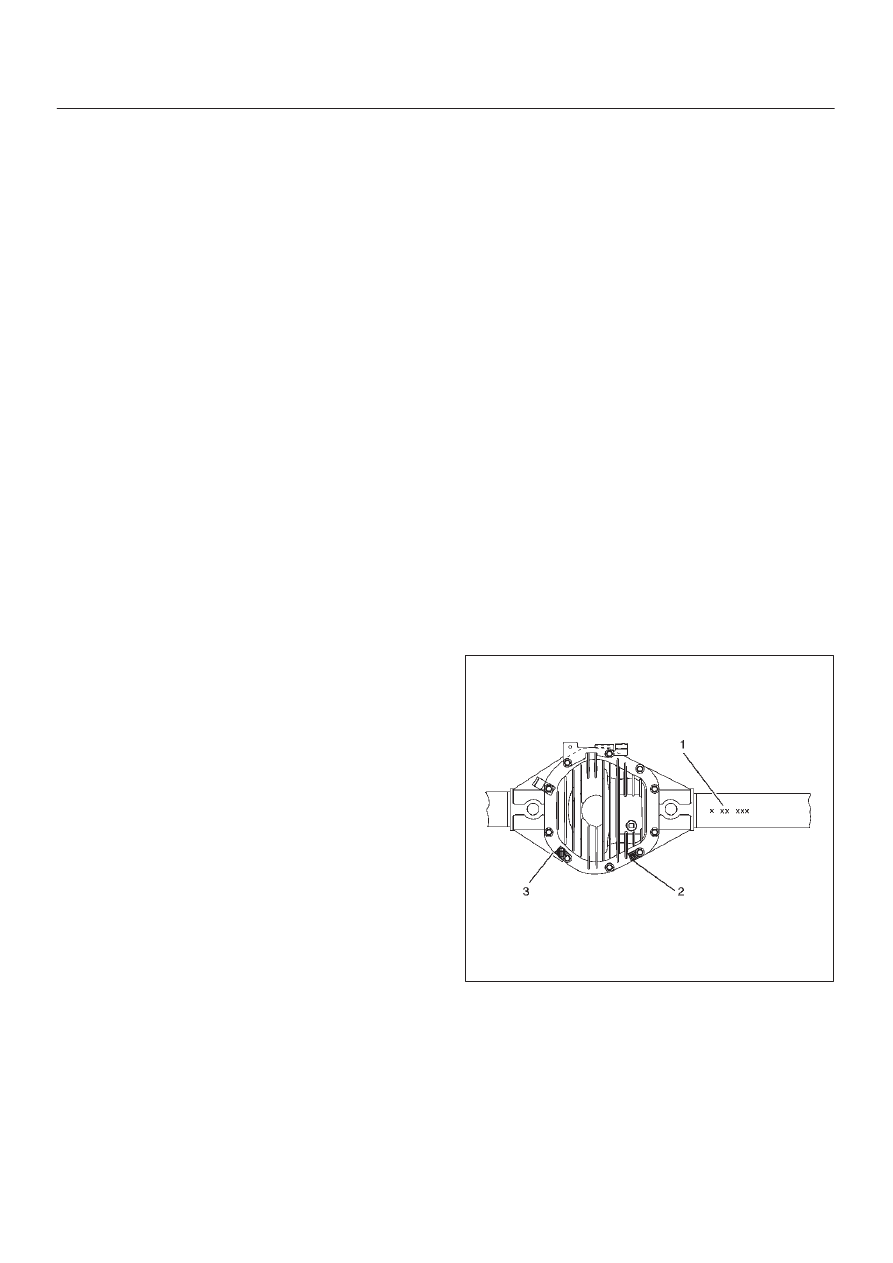

Rear Axle Identification

The Bill of Material and build date information(1) is

stamped on the right axle tube on the rearward side.

The axle ratio is identified by a tag(3) which is secured by

a cover bolt. If the axle has limited-slip differntial, it also

will be identified with a tag(2) secured by a cover bolt.

425RX001