Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 45

2A–26 POWER–ASSISTED STEERING SYSTEM

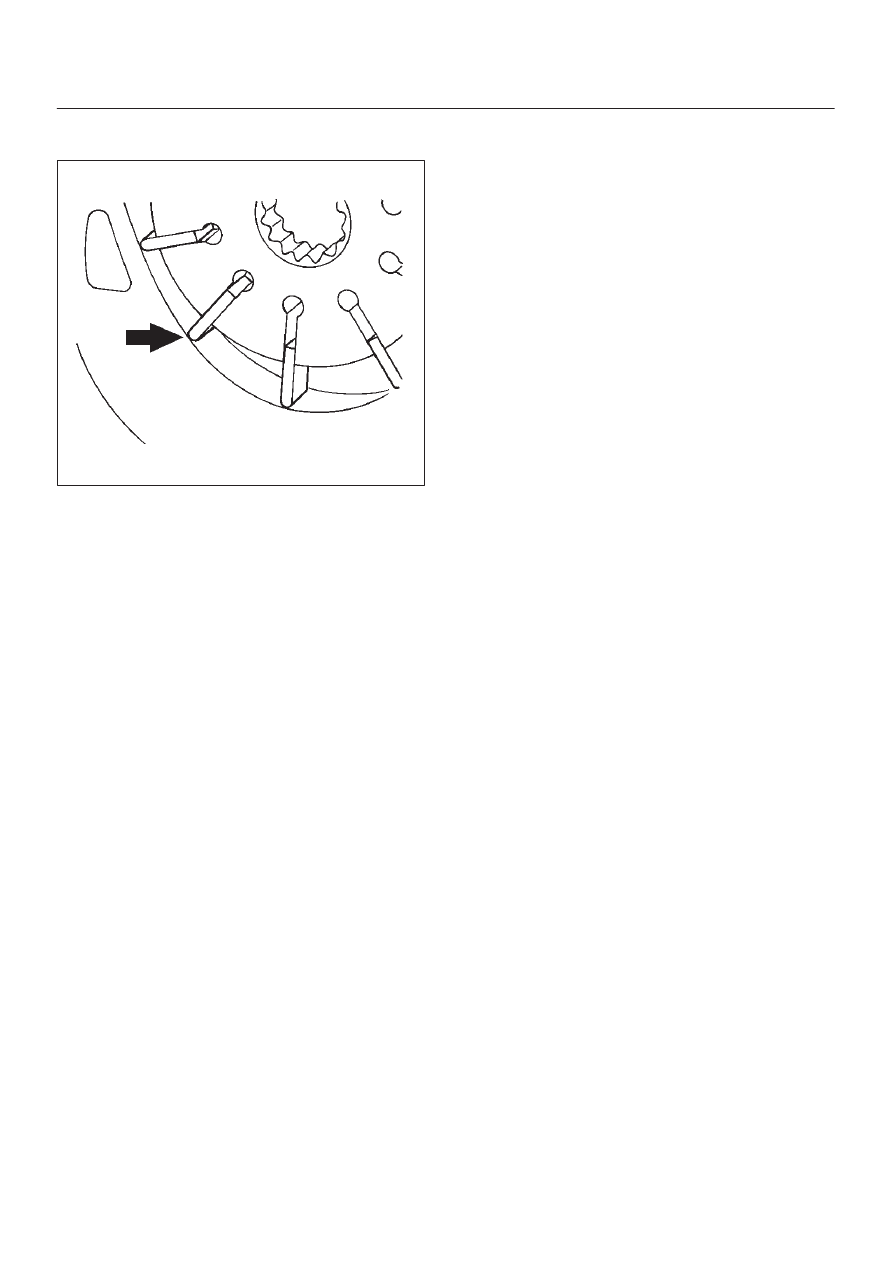

3. Install the vanes to roter with curved face in contact

with the inner wall of cam.

442RS005

4. Install rotor and vanes to cam.

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to

discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate may

cause poor pump performance, pump seizure or oil

leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it to

specified torque.

Torque: 24 N·m (17 lb ft)

11. Install suction pipe with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it to

specified torque.

Torque: 10 N·m (87 lb in)

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to

discard used O-ring. Tighten the connector to

specified torque.

Torque: 59 N·m (43 lb ft)

14. Install pressure switch assembly and tighten it to

specified torque.

Torque: 18 N·m (13 lb ft)