Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 44

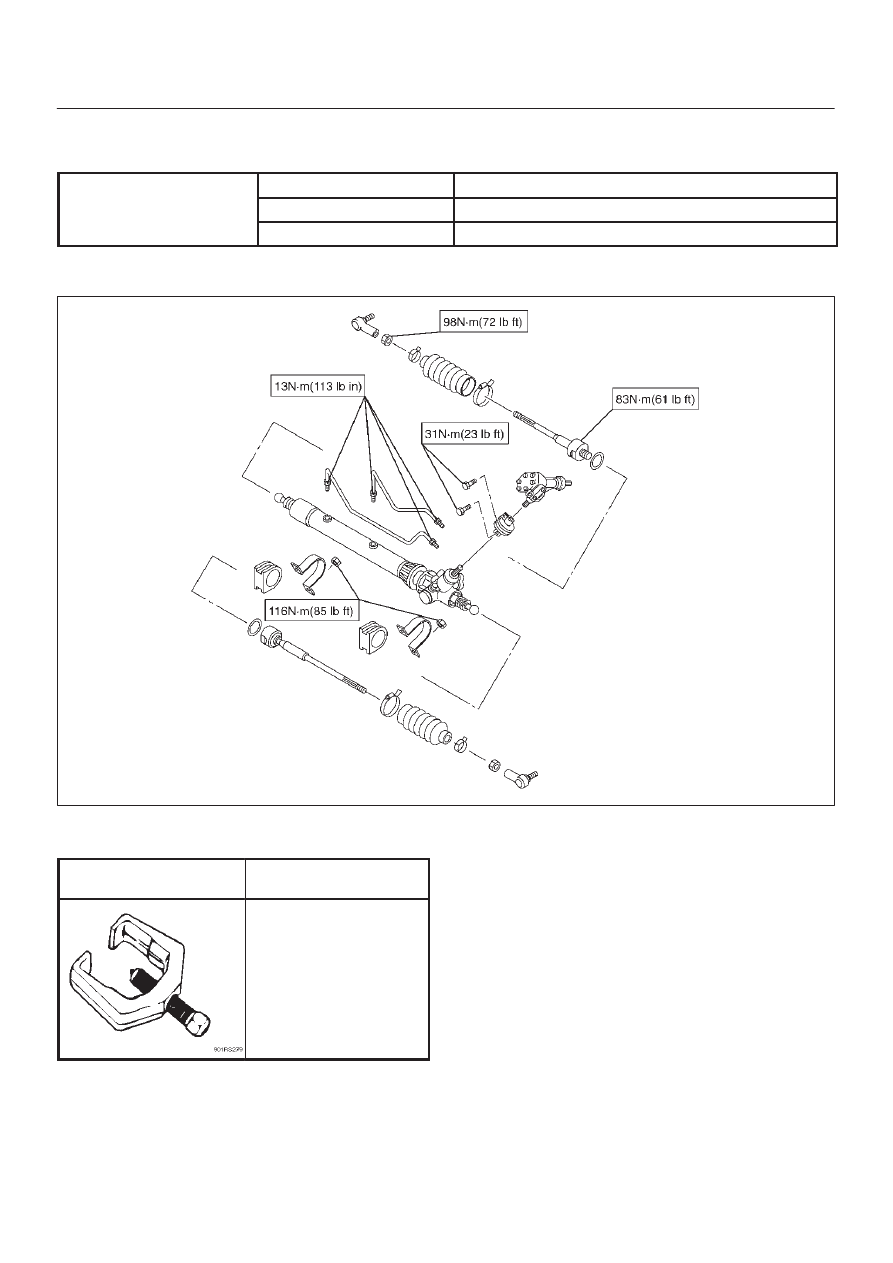

2A–22 POWER–ASSISTED STEERING SYSTEM

Main Data and Specifications

General Specifications

Power Steering unit

Type

Rack and pinion

Rack stroke

152 mm (5.98 in)

Lock to lock

3.64

Torque Specifications

440R100003

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

J–29107

Tie rod end remover