Infiniti M35/M45 Y50. Manual - part 654

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-1089

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis Logic

NBS005GS

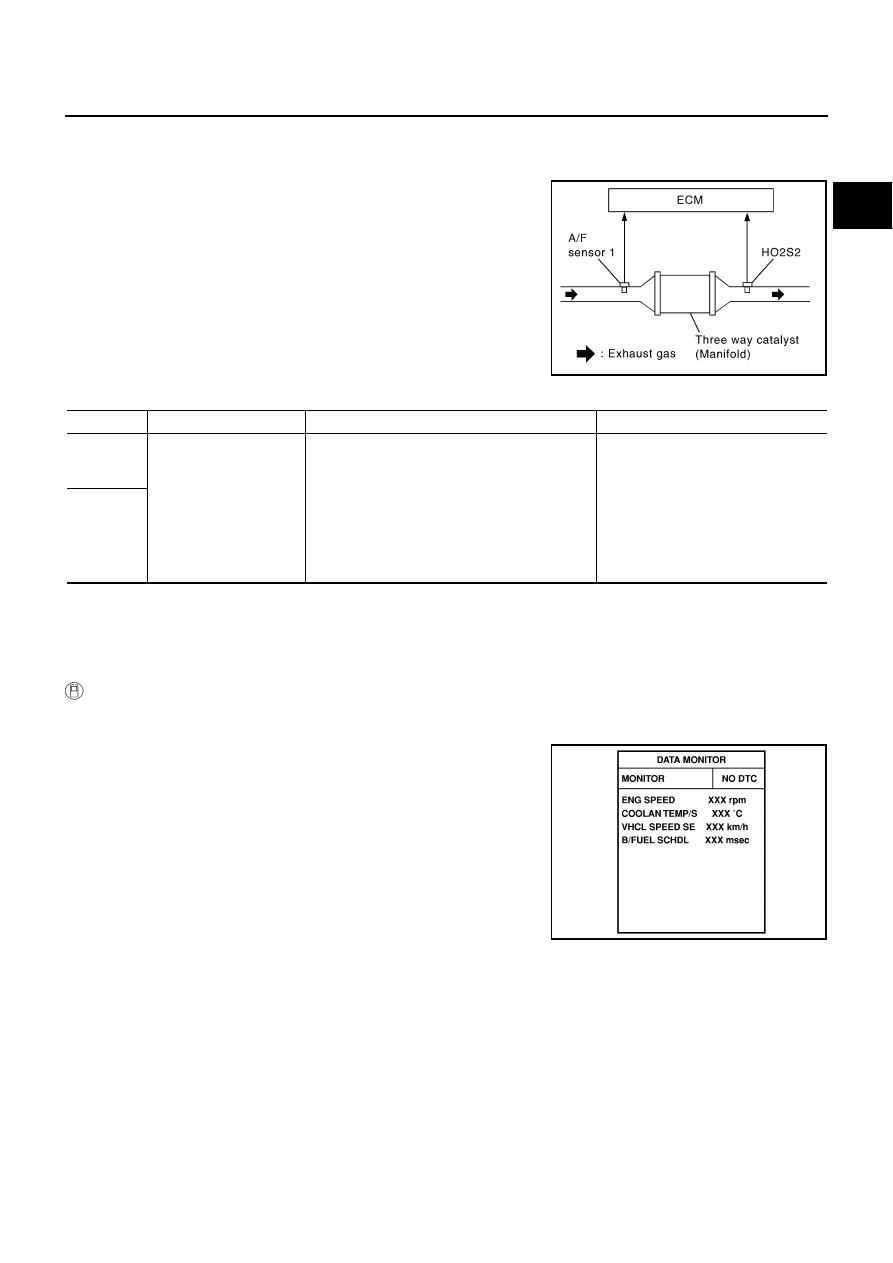

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC Confirmation Procedure

NBS005GT

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1.

Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2.

Start engine and warm it up to the normal operating tempera-

ture.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

5.

Let engine idle for 1 minute.

6.

Make sure that “COOLAN TEMP/S” indicates more than 70

°

C

(158

°

F).

If not, warm up engine and go to next step when “COOLAN

TEMP/S” indication reaches to 70

°

C (158

°

F).

7.

Open engine hood.

PBIB2055E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0420

0420

(Bank 1)

Catalyst system efficiency

below threshold

●

Three way catalyst (manifold) does not operate

properly.

●

Three way catalyst (manifold) does not have

enough oxygen storage capacity.

●

Three way catalyst (manifold)

●

Exhaust tube

●

Intake air leaks

●

Fuel injector

●

Fuel injector leaks

●

Spark plug

●

Improper ignition timing

P0430

0430

(Bank 2)

SEF189Y