Infiniti M35/M45 Y50. Manual - part 402

BASIC SERVICE PROCEDURE

EC-81

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

10.

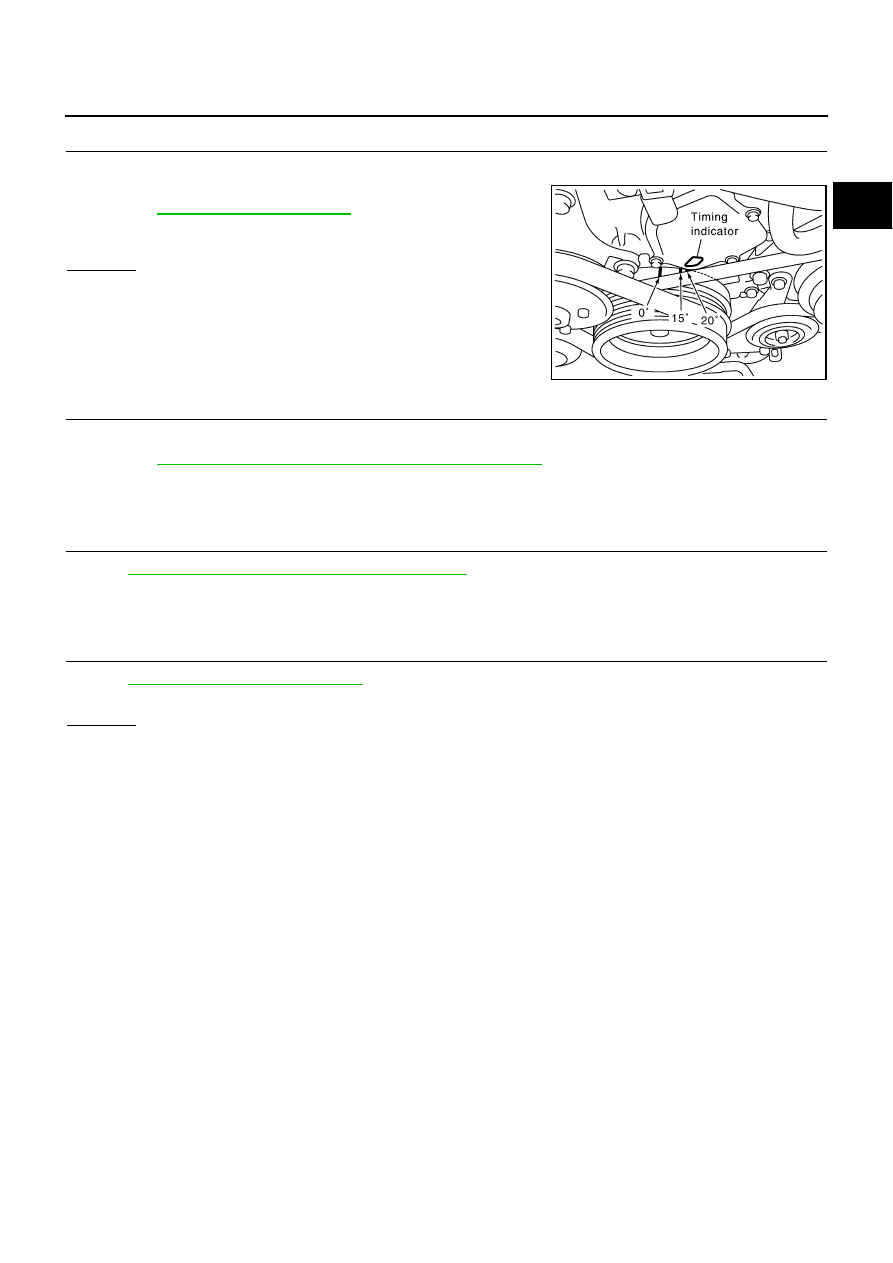

CHECK IGNITION TIMING

1.

Run engine at idle.

2.

Check ignition timing with a timing light.

Refer to

OK or NG

OK

>> GO TO 19.

NG

>> GO TO 11.

11.

PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1.

Stop engine.

2.

Perform

EC-86, "Accelerator Pedal Released Position Learning"

>> GO TO 12.

12.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform

EC-86, "Throttle Valve Closed Position Learning"

>> GO TO 13.

13.

PERFORM IDLE AIR VOLUME LEARNING

Refer to

EC-86, "Idle Air Volume Learning"

.

Is Idle Air Volume Learning carried out successfully?

Yes or No

Yes

>> GO TO 14.

No

>> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

15

±

5

°

BTDC (in P or N position)

PBIB1602E